TOPICS

Introduction Detail drawing

Assembly drawing

Introduction

Working drawing is a set of drawing used during the work of making a product.

DEFINITION

Detail drawing

Detail drawing

Working drawing

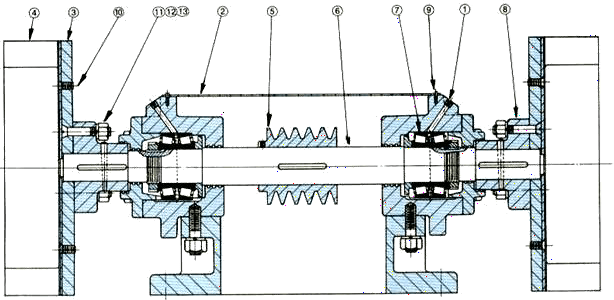

Assembly drawing is a drawing of various parts of a machine or structure assembled in their relative working positions.

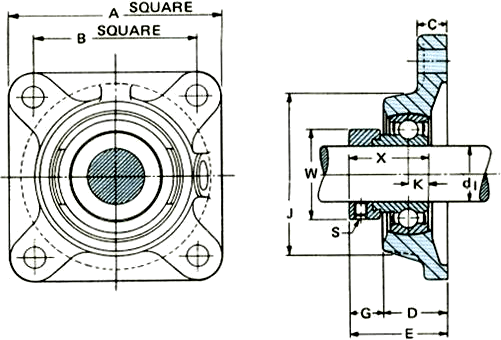

Detail drawing is a multiview representation gof a single part with dimensions and notes.

DEFINITION

Detail drawing conveys the information

and instructions for manufacturing the part.

PURPOSE

Assembly drawing conveys

- completed shape of the product.

- overall dimensions.

- relative position of each part.

- functional relationship among various components.

Detail Drawing

2.2 Size description

2.1 Shape description

Object’s views

INFORMATION IN DETAIL DRAWING

1. General information

Title block

2. Part’ s information

2.3 Specifications

Notes

GENERAL INFORMATION

- Name of company

- Title of drawing (usually part’s name)

- Drawing sheet number

- Name of drafter, checker

- Relevant dates of action (drawn, checked, approved etc.)

- Revision table

- Unit

- Scale

- Method of projection

PART’ S INFORMATION

Shape

Size

Specifications

- Orthographic drawing

- Pictorial drawing

- Dimensions and Tolerances

- Part number, name, number required

- Type of material used

- General notes

- Surface finish

- General tolerances RECOMMENDED PRACTICE

draw all parts using the same scale.

Otherwise, the scale should be clearly note under each part’s drawing.

PLACING AN INFORMATION

(This course)

Completed dimension orthographic drawing

Part No., Part name, material, Number required

Notes

Unit, fillets & rounds sizes etc.

Title block

EXAMPLE : Interpreting detail drawing

Revision table

Assembly Drawing

TYPES OF ASSEMBLY DRAWING

-

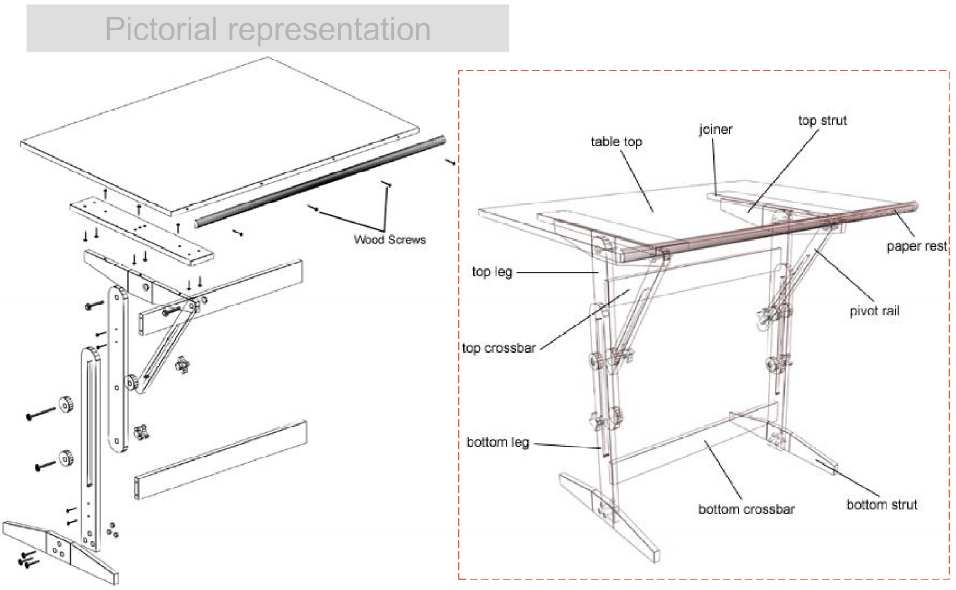

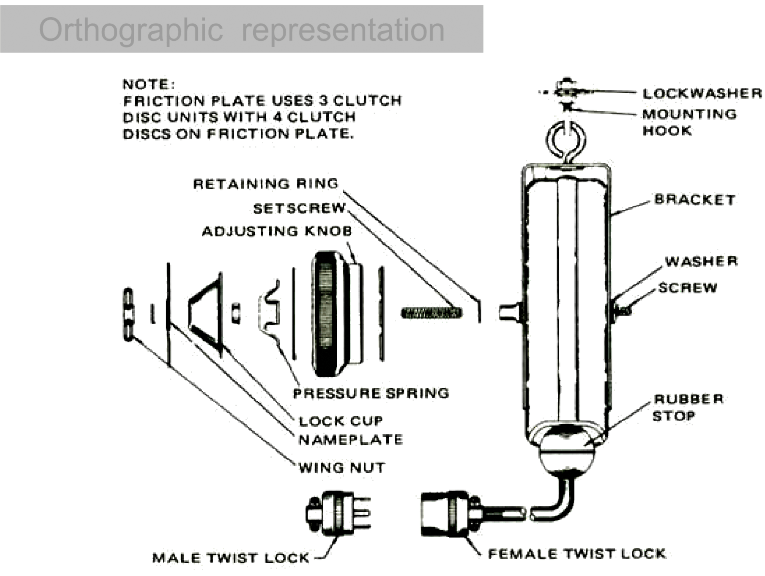

Exploded assembly drawings

The parts are separately display, but they are aligned according to their assembly positions and sequences.

-

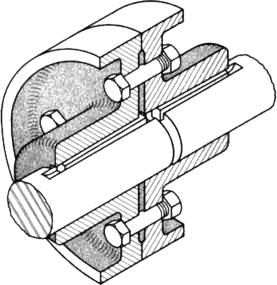

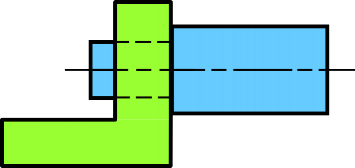

General assembly drawings.

All parts are drawn in their working position.

- EXPLODED ASSEMBLY

- EXPLODED ASSEMBLY

Pictorial representation

Finished product

-

EXPLODED ASSEMBLY

Orthographic representation

Pictorial

Orthographic

- GENERAL ASSEMBLY

Only dimensions relate to

machine’s operation are given in tabulated form (not shown).

Only dimensions relate to machine’s operation are given.

2. GENERAL ASSEMBLY

Locate above or beside the title block. Fill the table from the bottom.

PART LIST (BOM)

|

3 |

SET SCREW |

1 |

Stainless Steel,

M3 HEX SOCK CUP PT |

|

2 |

SHAFT |

1 |

Stainless Steel |

|

1 |

SUPPORT |

2 |

Cast Iron |

|

NO. |

PART NAME |

REQD. |

MATL. & NOTE |

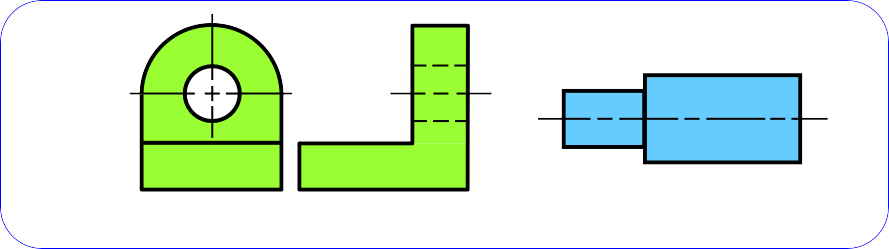

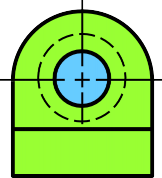

EXAMPLE : Selection of a necessary view

Student A Student B

Which is an appropriate view for assembly drawing ?

Hidden lines usually omit unless they are absolutely necessary to illustrate some important feature that the reader might otherwise miss.

GENERAL PRACTICE POINTS TO CONSIDER

- Surface finishing

- Tolerance

– Size

– Geometry

SURFACE FINISHING

Surface finishing means the quality of a surface. It relates to the level of roughness of a surface.

Purpose

- To control the accuracy in positioning and tightness between mating parts.

- To reduce the friction, especially for the part moves relative to other parts.

Tolerance is the total amount dimension may vary.

TOLERANCE

It is defined as the difference between the upper and lower limits.

Purpose

- To control an interchangeability of parts.

- To ensures the mating part will have a desired fit.