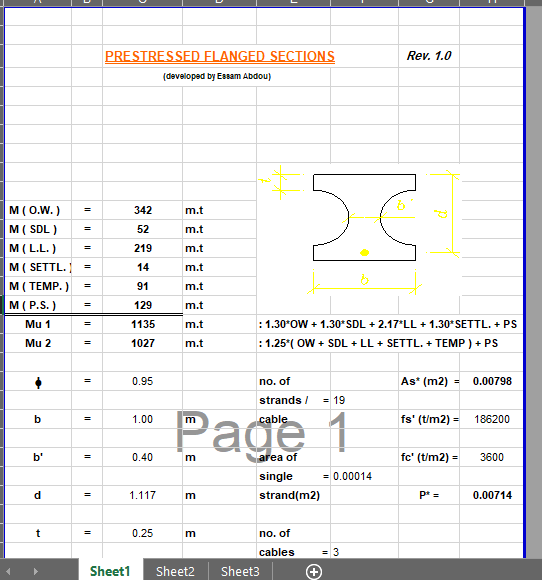

PRESTRESSED FLANGED SECTIONS

Prestressed flanged sections are structural members commonly used in construction and engineering projects, particularly in the design of bridges and other long-span structures. These sections consist of a reinforced concrete beam with a flange, which is a widened portion at the top and/or bottom of the beam, and prestressing tendons. Prestressing is a technique used […]

PRESTRESSED FLANGED SECTIONS Read More »