STRUCTURAL SYSTEMS IN HIGH-RISE BUILDINGS

INTRODUCTION

It is difficult to distinguish the characteristics of a building which categorize it as tall/ High Rise.

In a typical single-storey area, a five-story building will appear tall.

In large cities, a structure must pierce the sky around 70 to 100 stories if it is to appear tall in comparison with its immediate neighbors.

INTRODUCTION AND DEFINITION

High rise is defined differently by different bodies

- Emporis standards

-

“A multi-story structure between 35-100 meters tall, or a building of unknown height from 12-39 floors is termed as high rise.

- The International Conference on Fire Safety –

-

“Any structure where the height can have a serious impact on evacuation ”

- Massachusetts, United States General Laws –

-

A high-rise is being higher than 70 feet (21 m).

Buildings higher than 100m is termed as skyscraper according to emporis.

Buildings 300m or higher is termed as super tall and buildings 600m or taller is termed as mega-tall.

In this study we shall consider all buildings above 35 meters (115 feet)

DEMAND FOR HIGH-RISE BUILDINGS

High rise buildings are becoming more prominent these days due to following reasons

- Scarcity of land

- Increasing demand for business and residential space

- Economic growth

- Technological advancement

- Innovations in structural systems

- Desire for aesthetics in urban cities

- Cultural significance and prestige

- Human aspiration to build higher

- Scarcity of land

Dr. Fazlur Rahman Khan (Structural Engineer)

He has been called the “Einstein of structural engineering” and the “Greatest Structural Engineer of the 20th Century” for his innovative use of structural systems that remain fundamental to modern skyscraper design and construction.

Innovations: Tube structural systems, Framed tube, Trussed tube and X-bracing, Bundle tube, Tube in tube, Outrigger and belt truss, Concrete tube structures & Shear wall frame interaction system

DEVELOPMENT OF STRUCTURAL SYSTEM

-

First Generation 1780-1850

-

The exterior walls of these buildings consisted of stone or brick, although sometimes cast iron was added for decorative purposes.

-

The columns were constructed of cast iron, often unprotected; steel and wrought iron was used for the beams; and the floors were made of wood.

-

Second Generation 1850-1940

- The second generation of tall buildings, which includes the Metropolitan Life Building (1909), the Woolworth Building (1913), and the Empire State Building (1931), are frame structures, in which a skeleton of welded or riveted-steel columns and beams, often encased in concrete , runs through the entire building.

DEVELOPMENT OF STRUCTURAL SYSTEMS

- Third Generation 1940-present

- Buildings constructed from after World War II until today make up the most recent generation of high-rise buildings.

- Within this generation there are those of steel- framed construction (core construction and tube construction), reinforced concrete construction (shear wall), and steel-framed reinforced concrete construction.

- Hybrid systems also evolved during this time. These systems make use more than one type of structural system in a building.

-

Structural system classification

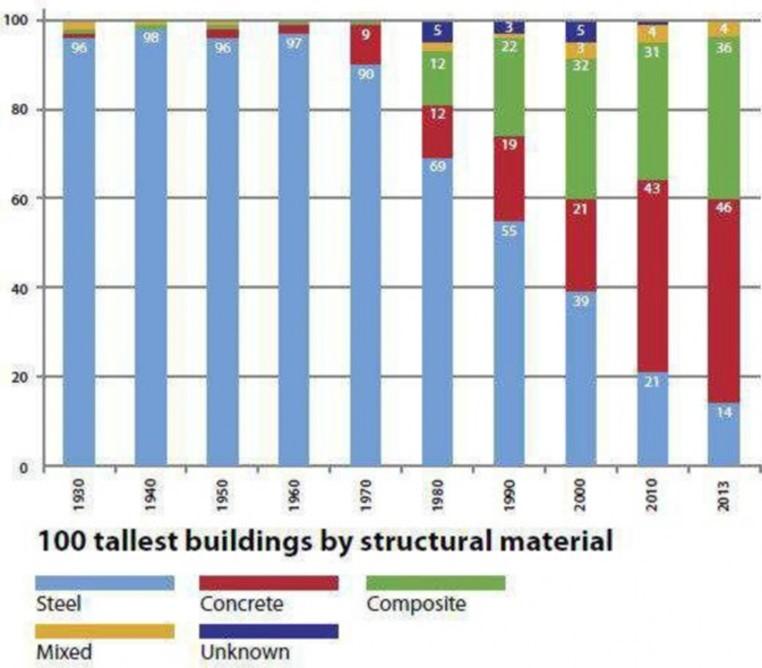

TALL BUILDING TRENDS

Considering the worlds 100 tallest buildings in 1990:

- 80 percent were located in North America.

- Almost 90 percent were exclusively office use.

-

More than half were constructed of steel.

In 2013, for the world’s 100 tallest buildings:

- The largest share (43 percent) are now in Asia. (Only one new 200-m-plus building was built in North America in 2013, compared to 54 in Asia.)

- Less than 50 percent are exclusively office use. Almost a quarter are mixed- use and 14 percent are residential.

-

Almost half were constructed of reinforced concrete and only 14 percent of

steel. (The remaining are composite or mixed structural materials.)

TALL BUILDING TRENDS

- 80 percent were located in North America.

A composite tall building utilizes a combination of both steel and concrete acting compositely in the main structural elements.

A mixed—structure tall building is any building that utilizes distinct steel or concrete systems above or below each other.

STRUCTURAL CONCERNS

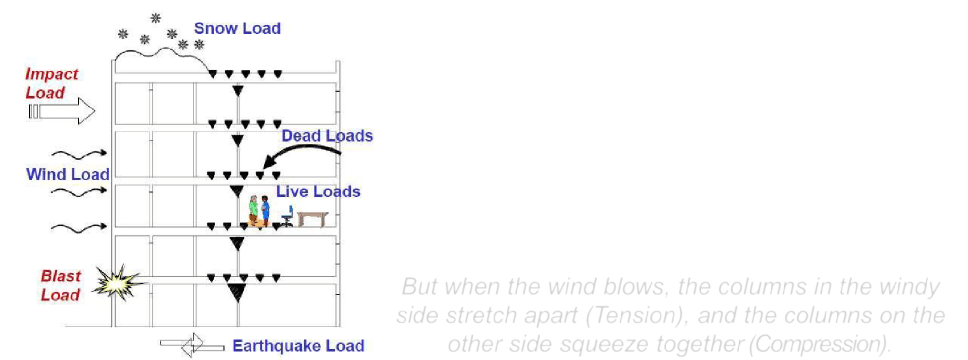

The skyscraper pushes down on into the ground. But when the wind blows, the columns in the windy side stretch apart (Tension), and the columns on the other side squeeze together (Compression).

-

The primary structural skeleton of a tall building can be visualized as a vertical cantilever beam with its base fixed in the ground. The structure has to carry the vertical gravity loads and the lateral wind and earthquake loads.

STRUCTURAL CONCERNS

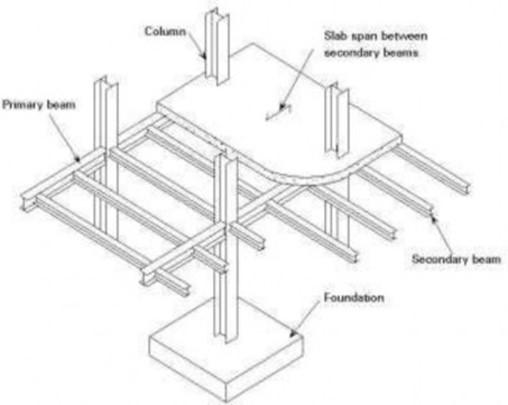

Fighting gravity

-

The weight of the building is supported by a

group of vertical columns

- Each floor is supported by horizontal steel/concrete girders running between vertical columns.

-

Curtain wall made of steel and concrete

attaches to the outside

Wind resistance

-

Buildings taller than 10 storeys would generally require additional

steel for lateral system.

STRUCTURAL CONCERNS

-

For taller skyscrapers, engineers have to construct especially strong cores through the center of the building for the wind resistance.

- The effects of wind can also be minimized by aerodynamic shaping of the building. Wind tunnel testing considers appropriate loading for overall lateral system design and cladding design, and predicts motion perception and pedestrian level effects.

-

Use of damping systems

as the building becomes taller and the building’s sway due to lateral forces becomes critical, there is a greater demand on the girders and columns that make up the rigid-frame system to carry lateral forces.

-

CLASSIFICATION OF TALL BUILDING STRUCTURAL SYSTEMS

Can be classified based on the structural material used such as concrete or steel

Structural systems of tall buildings can also be divided into two broad categories:

- 1) INTERIOR STRUCTURES

-

2) EXTERIOR STRUCURES

- This classification is based on the distribution of the components of the primary lateral load-resisting system over the building.

- This classification is based on the distribution of the components of the primary lateral load-resisting system over the building.

- A system is categorized as an interior structure when the major part of the lateral load resisting system is located within the interior of the building.

- Likewise, if the major part of the lateral load-resisting system is located at the building

perimeter, a system is categorized as an exterior structure.

It should be noted, however, that any interior structure is likely to have some minor components of the lateral load-resisting system at the building perimeter, and any exterior structure may have some minor components within the interior of the building.

By

INTERIOR STRUCTURAL

SYSTEM

-

1)RIGID FRAME

-

A rigid frame in structural engineering is the load- resisting skeleton constructed with straight or curved members interconnected by mostly rigid connections which resist movements induced at the joints of members. Its members can take bending moment, shear, and axial loads.

-

Can build upto 20 to 25 floors

-

2)SHEAR WALL STRUCTURE

-

Concrete continuous vertical walls may serve both architecturally partitions and structurally to carry gravity and lateral loading. Very high in plane stiffness and strength make them ideally suited for bracing tall building

-

Usually built as the core of the building

-

Can build upto 35 Floors

Seagram

building

Shear wall core

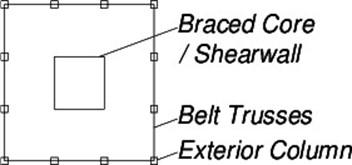

3) OUTRIGGER STRUCTURES

-

The core may be centrally located with outriggers extending on both sides or in some cases it may be located on one side of the building with outriggers extending to the building columns on the other side

-

The outriggers are generally in the form of trusses (1 or 2 story deep) in steel structures, or walls in concrete structures, that effectively act as stiff headers inducing a tension compression couple in the outer columns.

-

Belt trusses are often provided to distribute these tensile and compressive forces to a large number of exterior frame columns.

-

Build upto 150 floors

-

-

- 1) Tube system

- The tube system concept is based on the idea that a building can be designed to resist lateral loads by designing it as a hollow cantilever perpendicular to the ground.

- In the simplest of the tube, the perimeter of the exterior consists of closely spaced columns that are tied together with deep spandrel beams through moment connections.

- This assembly of columns and beams forms a rigid frame that amounts to a dense and strong structural wall along the exterior of the building.

-

The different tubular systems are- 1) Framed tube 2) Braced tube 3) Bundled tube 4) Tube in tube

2) Diagrid systems

-

With their structural efficiency as a varied version of the tubular systems, diagrid structures have been emerging as a new aesthetic trend for tall buildings in this era of mixture of different styles.

-

Early designs of tall buildings recognized the effectiveness of diagonal bracing members in resisting lateral forces.

-

Most of the structural systems deployed for early tall buildings were steel frames with diagonal bracings of various configurations such as X, K, and chevron. However, while the structural importance of diagonals was well recognized, the aesthetic potential of them was not appreciated since they were considered obstructive for viewing the outdoors.

-

Efficiently resists lateral shear by axial forces in the

diagonal members but have Complicated joints

Hearst tower, New York

- Space truss

- Space truss

- Space truss structures are modified braced tubes with diagonals connecting the exterior to interior. In a typical braced tube structure, all the diagonals, which connect the chord members – vertical corner columns in general, are located on the plane parallel to the facades.

-

However, in space trusses, some diagonals penetrate the interior of the building.

-

Exo skeleton structure

-

- In exo-skeleton structures, lateral load-resisting systems are placed outside the building lines away from their facades.

-

Due to the system’s compositional characteristics, it acts as a primary building identifier – one of the major roles of building facades in general cases.

-

Fire proofing of the system is not a serious issue due to

-

its location outside the building line.

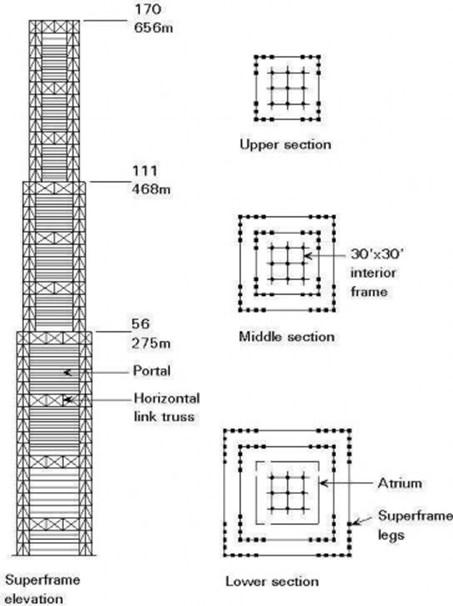

- Super frame structures

-

Superframe structures can create ultra high-rise buildings upto 160 floors.

-

Superframes or Megaframes assume the form of a portal which is provided on the exterior of a building.

- The frames resist all wind forces as an exterior tubular structure. The portal frame of the Superframe is composed of vertical legs in each corner of the building which are linked by horizontal elements at about every 12 to 14 floors.

- Since the vertical elements are concentrated in the corner areas of the building, maximum efficiency is obtained for resisting wind forces.

Case Study : PETRONAS TOWER

Petronas tower is a symbol of national pride and shows the nation’s advancement in the word economy and technologies. Conrete was used for its construction mainly because it was easily available and cheap when compared with steel, which was a new material for the builders.

The architect successfully incorporated malaysian and Islamic motiffs in the design. The skybridge was an important feature of the design which was implemented later. Petronas tower has ‘tube in tube’ structural system. The structural members are made with high strength concrete which was cast in site. The perimeter columns are held together with the help of ring beams. The internal core structure is made of concrete shear walls. The building didn’t require extra damping systems because the heavy structural members made of concrete. Even though no new advncements in technology was made during the project , the available technology was used smartly.

BURJ KHALIFA DUBAI, UAE

- The Burj Dubai project is designed to be the centerpiece of the large scale Burj Dubai Development that rises into the sky to an unprecedented height of 800 meters and that consists of more than 160 floors.

- The decision to build Burj Khalifa is reportedly based on the government’s decision to diversify from an oil based economy to one that is service and tourism based.Unlike many super-highrise buildings with deep floor plates,

-

the Y-shape floor plans of Burj Dubai maximize views and

provide tenants with plenty of natural light.

-

According to officials, it is necessary for projects like Burj Khalifa to be built in the city to garner more international recognition, and hence investment. The structural system of burj khakifa was a new system developed for the building. The system is called ‘butressed core’ . In this system the lateral loads and gravity loads are shared equally between the interior core and perimeter structural systems linked by the link beam which makes the structure super strong.

FUTURE TALL BUILDINGS

-

Nothing could be more stunning than the latest generation of skyscrapers, known as the ‘supertalls’.A tower has to be over 300 metres high to qualify as a supertall, but there is no shortage of contenders: at 829.8 metres high, the Burj Khalifa in Dubai is undeniably the world’s tallest building, but it won’t be for very long as the race to build upwards continues around the world.

-

We are entering the era of the “megatall.” This term is now officially being used by the Council to describe buildings over 600 meters in height, or double the height of a supertall .

CONCLUSION

-

With the present technology and known materials , it is possible to

build more higher and faster.

- It is now possible to build skyscrapers so fast using pre- fabricated units that it can lead to environmental problems, stress on resources and overcrowding if not controlled.

- To build higher the base of the building will have to be made wider. The bundled tube system was a great innovation and was able to span great heights during it’s time , to attain the height of burj khalifa the bundled tube system will need a bigger base when compared with the buttressed core system.

-

New improved structural systems and new materials in the future can lead us to even greater heights and more stable buildings. It’s not technology holding buildings back. It’s money.

THANK YOU