BOOKS

AISC 360 -16 Specifications

(Free on web site www.aisc.org).

Steel Structures, 3rd Ed. by Zahid and Ashraf.

LRFD Steel Design Aids, 4th Ed. by Zahid (Always bring in the practical classes).

Unified design of steel structures book by Louis

Geschwindner.

Introduction To Steel Structures

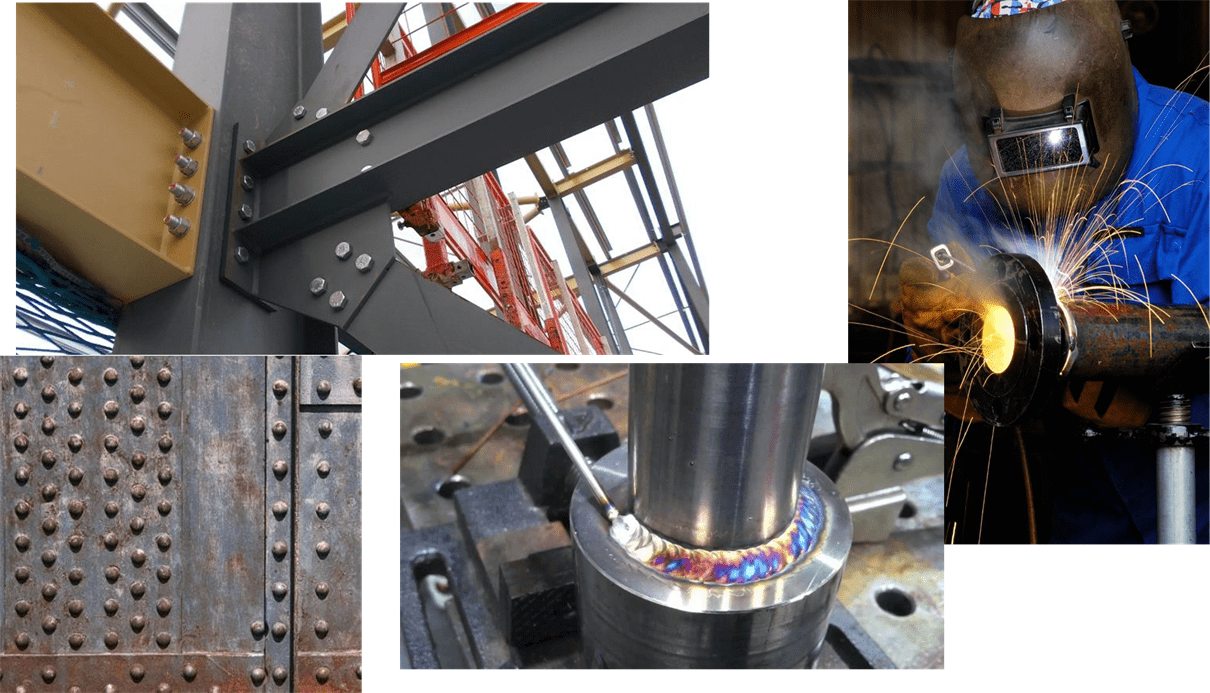

- Steel structures are assembly of structural steel shapes joined together by means of riveted / bolted or welded connections.

- Selection of a section out of those available in the market.

- Concrete structures are easily joined together by monolithic construction.

- But special methods are required to join individual members for steel structures.

Hot Rolled Sections

Cold Formed Sections

Cold Formed Sections

Cold Forming is a process where light gauge steel members are manufactured by rolling or shaping the steel after it is cold.

This process makes the

This process makes the

steel stronger.

steel stronger.

Steel Structure Frame work

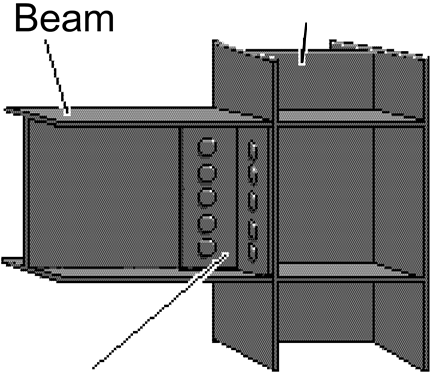

Connections

Column

Column

Bolted Connection

-

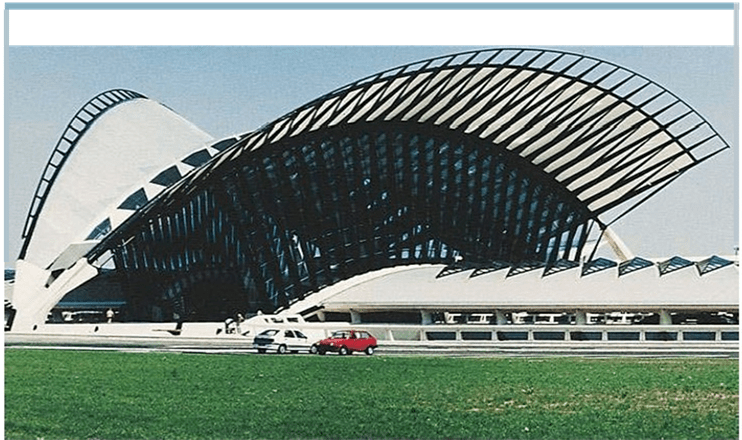

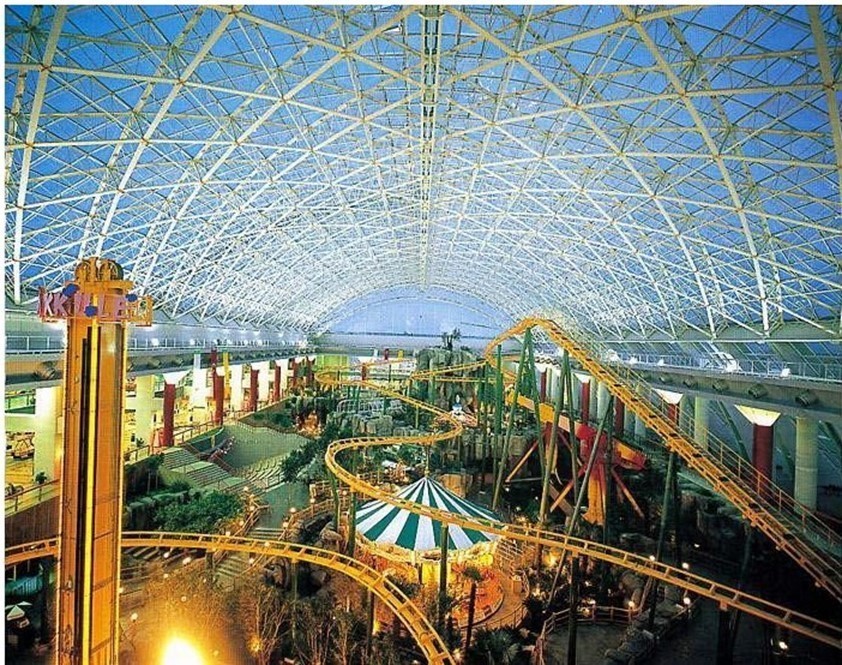

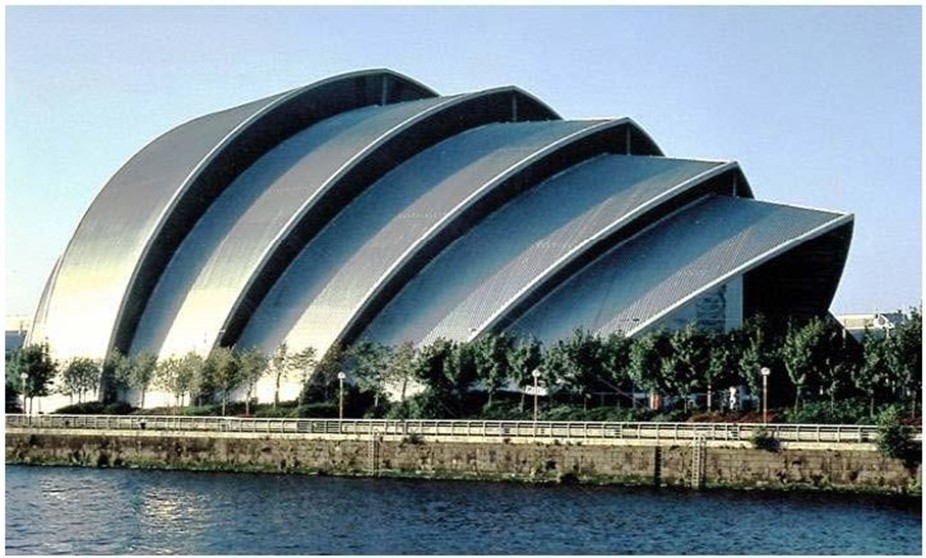

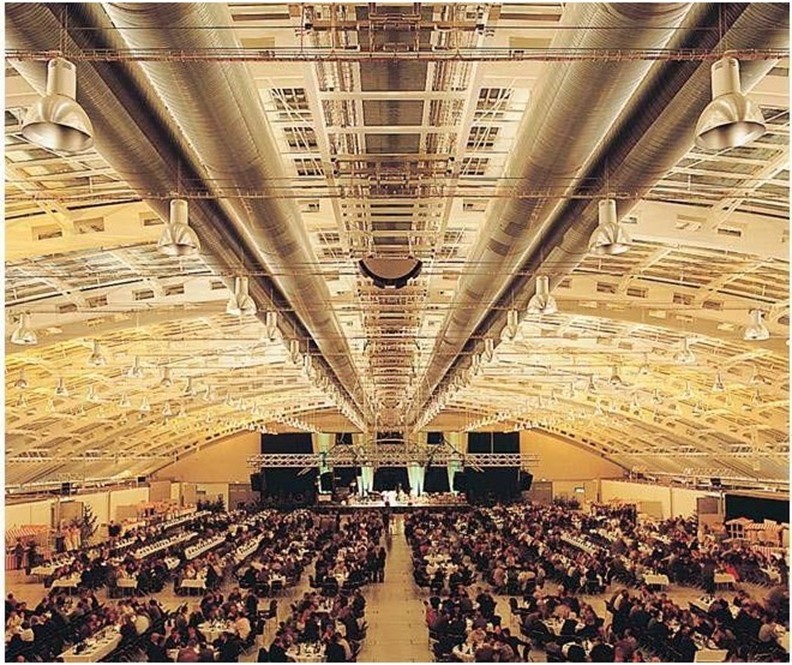

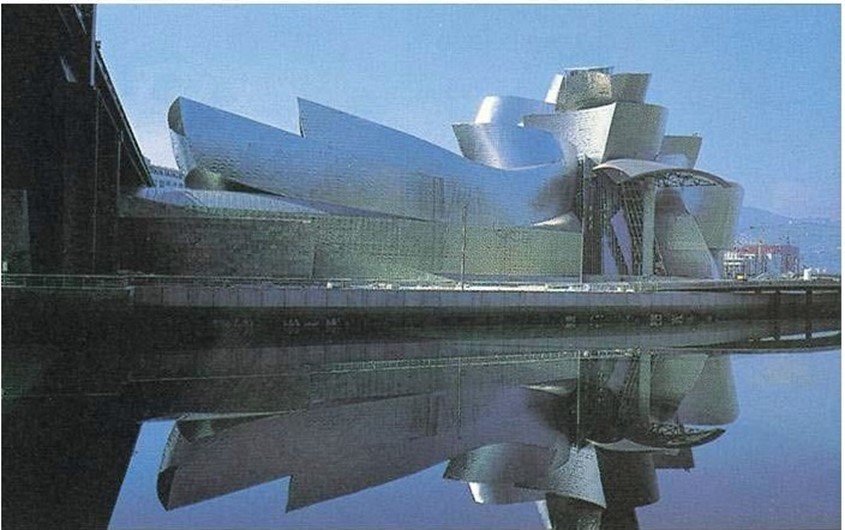

Steel construction is being used for almost every type of structure including multi- storey buildings, bridges, industrial buildings, towers, etc.

- There are two main structures:-

categories of steel

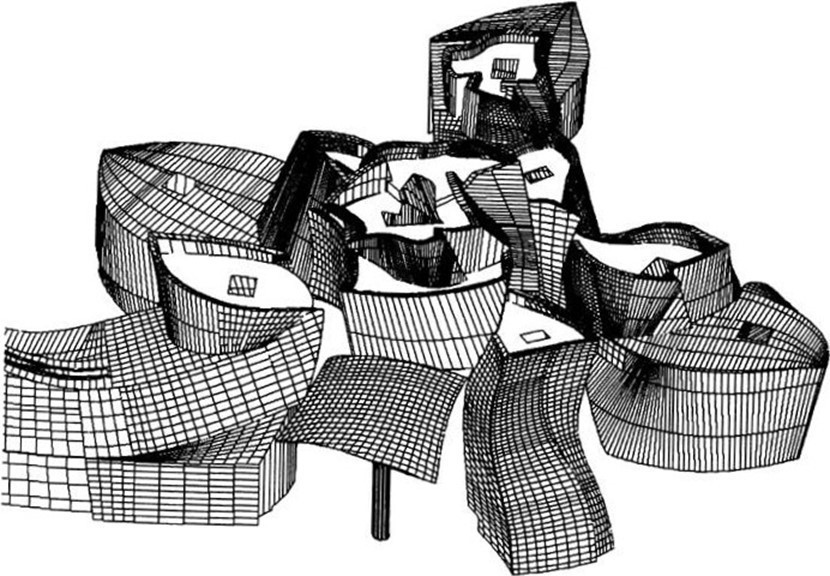

- Framework or skeletal systems.

- Shell systems.

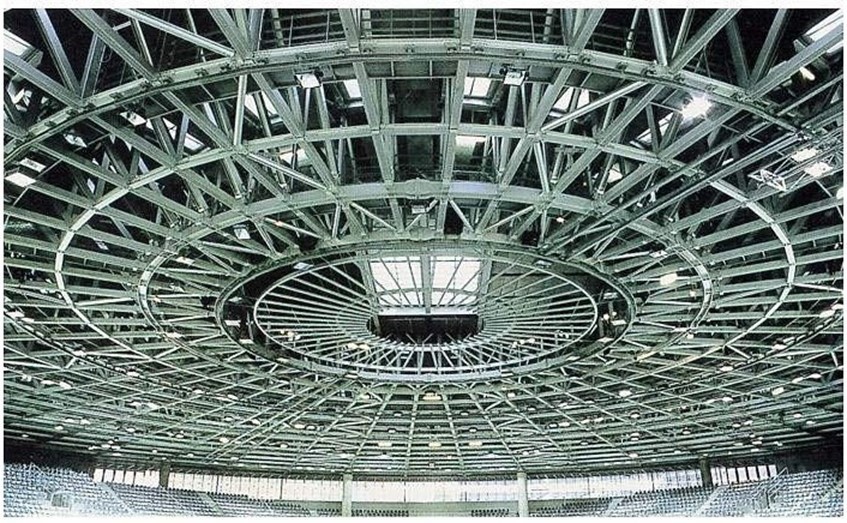

Framework Or Skeletal Systems

-

The main load carrying elements in this type are one-dimensional or line elements (such as beams, columns, etc.) forming two-dimensional or three- dimensional frames.

The main load carrying elements in this type are one-dimensional or line elements (such as beams, columns, etc.) forming two-dimensional or three- dimensional frames. -

Examples are:-

Multi-storey buildings, large halls, domes etc.

- Highway and railways large span bridges.

- Towers, poles, structural components of hydraulic works.

- All other trusses and rigidly connected frame structures.

- The frameworks of industrial buildings with their internal members such as crane girders, platforms, etc.

Shell Systems

The main load carrying elements in this category of structures are plates and sheets besides some skeletal members.

The main load carrying elements in this category of structures are plates and sheets besides some skeletal members.-

Examples are:-

- Gas tanks for the storage and distribution of gases.

- Tanks and reservoirs for the storage

of liquids.

- Bins and bunkers for the storage of loose material.

-

Special structures such as blast furnaces,

air heaters, etc.

- Large diameter pipes.

- All other plate and shell structures.

Freedom of Expression

Creativity

Creativity

Easy Extension

Easy Fixing of Facade

Easy and Efficient Fabrication

Express Function

Large Span

Large Span

No Limit of Architectural Design

No Limits of Architectural Design

Recycling ispossible

Slender columns,more space

Transparency

Visible Connections

Visible Connections

Weather Independent Construction

Advantages & Disadvantages of

Steel Construction

Merits of Steel Construction

-

Reliability

- Consistency and uniformity in properties.

- Better quality control because of factory manufacture.

- Large elasticity.

-

Ductility.

- Because of truly homogeneous and elastic material, steel satisfies most of the assumptions involved in the derivation of the analysis and design formulas and hence the results obtained are reliable.

- Because of truly homogeneous and elastic material, steel satisfies most of the assumptions involved in the derivation of the analysis and design formulas and hence the results obtained are reliable.

2. Industrial Behavior

- Hot Rolled steel sections are manufactured in factories.

-

Also, the members may be cut and prepared for

assembly in factories.

-

Only joining of these components is carried out at the site by installing rivets or bolts and by welding different components.

- Sometimes parts of the structure are also assembled in

the factories, that is, there is a great adaptation to

prefabrication. - Manual errors reduce greatly in such cases, the speed of construction increases and the total cost reduces.

3. Lesser Construction Time

- Because of the industrial nature of steel construction, progress of the work is very fast making the structures economical.

- The reason is that these structures can be put to use earlier.

- The reduction in labour cost and overhead charges and the benefits obtained from the early use of the building contribute to the economy.

4. High Strength And Light Weight Nature

- Steel provides high strength per unit weight.

-

Dead loads become lesser.

- Dead loads are a bigger part of the total loads on a structure.

- When dead load reduces, the underneath members become still smaller due to less weight acting on them.

- More important for long-span bridges, tall buildings, and for structures having poor foundation conditions.

- Dead loads are a bigger part of the total loads on a structure.

-

Factor (C) is defined as the ratio of the density of a

material () to the stress (Strength) it can carry (f) and is one of the least for steel.

|

Material |

C = / f (m-1) |

|

Aluminium |

1.1 x 10-4 |

|

Steel |

3.2 x 10-4 |

|

Wood |

4.5 x 10-4 |

|

Concrete |

24.0 x 10-4 |

5. Uniformity, Durability And

Performance

- Durability means long life of a structure.

- Steel is a very homogeneous and uniform material.

- It satisfies the basic assumptions of most of the analysis and design formulas.

- If properly maintained by painting, etc., the properties of steel do not change appreciably with time.

- Hence, steel structures are more durable.

-

Elasticity

- Steel behaves closer to design assumptions than most of the other materials because it follows Hooke’s law up to fairly high stresses.

- The stress produced remains proportional to the strain applied or the stress-strain diagram remains a straight line.

- The steel sections do not crack or tear before ultimate load and hence the moments of inertia of a steel structure can be definitely calculated.

-

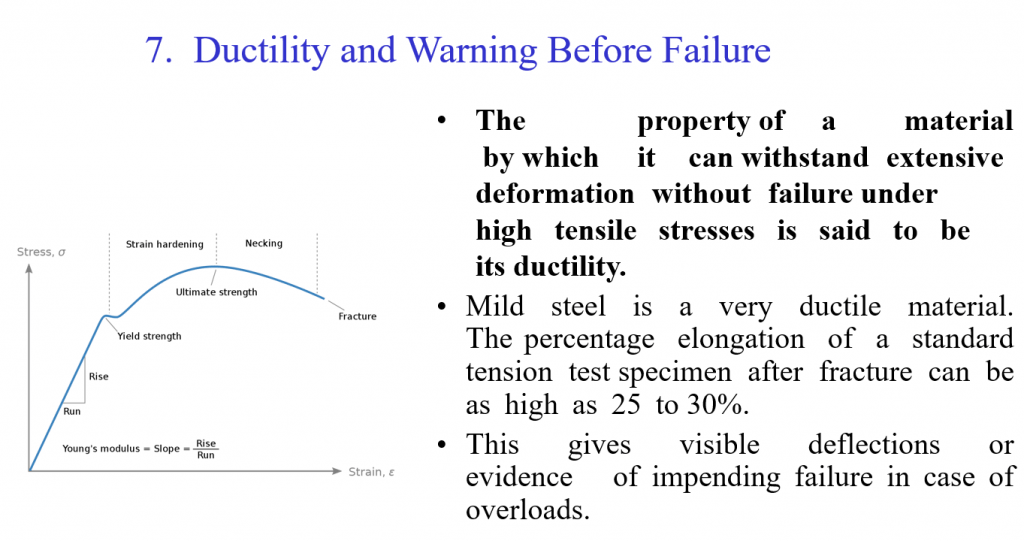

Ductility and Warning Before Failure

|

tension |

test specimen after |

fracture |

can |

be |

|

as high |

as 25 to 30%. |

- This gives visible deflections or evidence of impending failure in case of overloads

-

The extra loads may be removed from the structure to prevent collapse.

- Even if collapse does occur, time is available for occupants to vacate the building.

- Even if collapse does occur, time is available for occupants to vacate the building.

-

Additions To Existing Structures

- Additions to existing steel structures are very easy to be made.

- Connections between new and existing structures can be employed very effectively.

- New bays or even entire new wings of buildings can be added to existing steel frame buildings, and steel bridges may often be widened.

-

Possible Reuse

- Steel sections can be reused after a structure is disassembled.

-

Scrap Value

- Steel has a scrap value even though it is not reusable in its existing form.

-

Water-Tight And Air-Tight Construction

-

Steel structures provide completely

impervious construction.

- Structures like reservoirs, oil pipes, gas pipes, etc., are preferably made from structural steel.

-

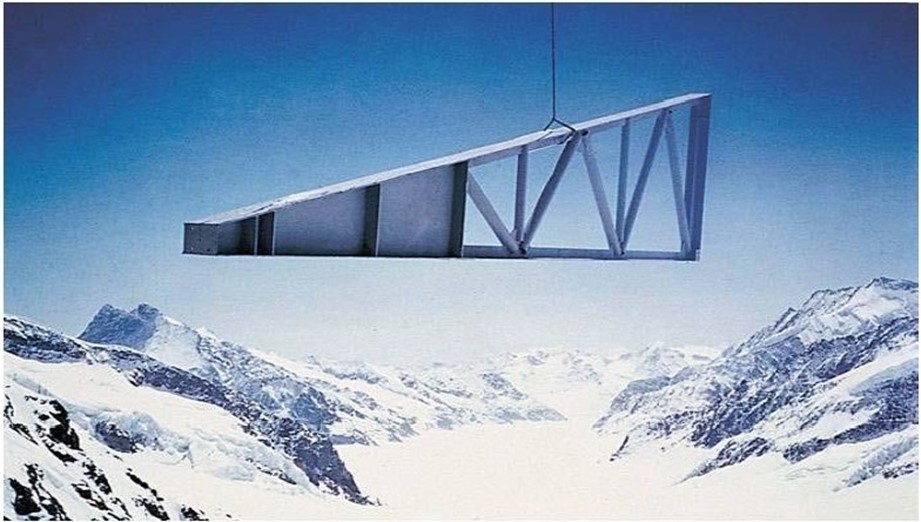

Long Span Construction

High-rise buildings, long span bridges and tall transmission towers are made up of structural steel.

Industrial buildings up to a span of 90 m can be designed by plate girders or trusses.

Bridge spans up to 260 m are made with plate girders.

For through truss bridges, spans of 300 m

have been used.

Temporary Construction

- For temporary structures, steel construction is always preferred.

-

Army constructions during war are mostly

made out of structural steel.

- The structures may be disassembled by opening few bolts, component parts are carried to new places and the structure is easily reassembled.

Demerits Of Steel Construction

1. High Maintenance Costs and Corrosion

- Most steels are susceptible to corrosion when freely exposed to air and water and must therefore be periodically painted.

-

This requires extra cost and special care.

- The use of weathering steels, in suitable design applications, tends to eliminate this cost.

- If not properly maintained, steel members can loose 1 to 1.5 mm of their thickness each year.

- Accordingly such constructions can loose weight up to 35% during their specified life and can fail under the external loads.

-

High Fireproofing Costs

-

Although steel members are incombustible, their strength is tremendously reduced at temperatures prevailing in fires.

- At about 400C, creep becomes much more pronounced.

- Creep is defined as plastic deformation under a constant load for a long period of time.

- This produces excessively large deflections / deformations of main members forcing the other members to higher stresses or even to collapse.

- Steel is an excellent conductor of heat and may transmit enough heat from a burning compartment of a building to start fire in other parts of the building.

- Extra cost is required to properly fire proof the building.

-

Susceptibility To Buckling

Buckling is a type of collapse of the members due to sudden large bending caused by a critical compressive load.

Buckling is a type of collapse of the members due to sudden large bending caused by a critical compressive load.- The steel sections usually consist of a combination

of thin plates.

- Further, the overall steel member dimensions are also smaller than reinforced concrete members.

-

If these slender members are subjected to compression, there are greater chances of buckling.

- Sometimes steel, when used for columns, is not very economical because considerable material has to be used merely to stiffen the columns against buckling.

-

High Initial Cost / Less

Availability

- In few countries, Pakistan is one such example, steel is not available in abundance.

- Hence, its initial cost is very high compared with the other structural materials.

- This is the most significant factor that has resulted in the decline of steel structures in these countries.

-

Aesthetics

-

For certain types of buildings, the steel form

is architecturally preferred.

- However, for majority of residential and office buildings, steel structures without the use of false ceiling and cladding are considered to have poor aesthetic appearance.

- A considerable cost is to be spent on such structures to improve their appearance.

- Cladding is a covering of metal, concrete, plastic or timber put on the surface of a structural member to completely encase it. The cladding not only protects the member but also improves its appearance.

Specifications

specifications.

-

These include formulas that guide the designer in checking strength, stiffness, proportions and other criteria that may govern the acceptability of the member.

-

There are a variety of specifications that have been

developed for both materials and structures.

- Each is based on years of research and experience gained through actual structural usage.

- Following specifications will be used in this class quite often:

|

1- |

AISC 360: |

American Institute of Steel Construction. |

|

2- |

AISI: |

American Iron and Steel Institute |

|

3- |

AWS: |

American Welding Society. |

|

4- |

AASHTO: |

American Association of State Highway and Transportation Officials. |

|

5- |

AREA: |

American Railway Engineering Association. |

|

6- |

ASTM: |

American Society for Testing and Materials. |

|

7- |

ASCE: |

American Society of Civil Engineers |

TYPES OF LOAD

1. Dead Load

- It almost retains its magnitude and point of application throughout the life of the structure and is denoted by D.

- This load is usually the self weight of the structure (not only this member but all other members resting on it).

- This is estimated by multiplying volume of a member with the standard density of the material of construction.

- This load constitutes a bigger part of the total load on a structure.

-

Live Load

- The load due to persons occupying the structure and their belongings, denoted by L.

- Its magnitude and point of application changes with time.

- In case of bridges, live load consists of weight of vehicles moving over the bridge.

-

Typical values for common occupancy types

are given in next slide.

|

Occupancy or Use |

Live Load (kg/m2) |

|

Private apartments, school class rooms |

200 |

|

Offices |

250 |

|

Fixed-seats, assembly halls, library reading rooms |

300 |

|

Corridors |

400 |

|

Movable seats assembly hall |

500 |

|

Wholesale stores, light storage warehouses |

600 |

|

Library stack rooms |

750 |

|

Heavy manufacturing, heavy storage warehouses, sidewalks and driveways subject to trucking |

1200 |

-

Self Load

- This is type of dead load, which is due to self weight of the member to be designed.

- For design, a reasonable value of self load depending on past experience is assumed in the start which is then compared with the actual self weight at the end.

- Corrections in design are made if necessary.

- Other types of loads are wind load, earthquake loads, water ad earth retaining loads and temperature loads, etc.

-

Imposed / Superimposed Load

- This term is used for all external loads, leaving the self weight, acting on the member to be designed.

- This includes snow load, wind load, earthquake load, etc. Part of dead load may also act as imposed load.

-

Service Loads

-

The maximum intensity of load expected during the life of the structure depending upon a certain probability of occurrence is called service load.

-

No additional factor of safety or overload factor is included in the service loads.

-

Factored Loads

-

-

Service loads increased by some factor of safety or

overload factor are called factored loads.

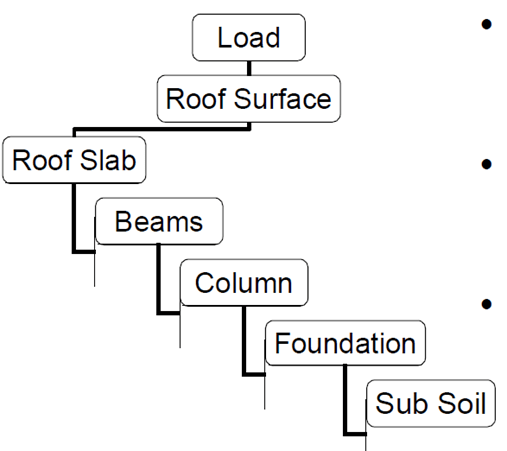

Mechanism Of Load Transfer

The load acts at the floor finish, goes to the underneath slab and transfers to the beams and walls.

This is then accumulated in the columns, moves to

the foundations and then finally dissipates in the

soil.

The terms member and support are defined relative to each other.

For the roof slab, beams and walls are

supports.

For the beams, columns are acting like supports, and for the columns, foundations are acting as supports.

Similarly, the underneath soil acts as support for the foundations.

Steel Structures Lectures are taken from

Steel Structures book by Dr. Zahid Ahmed

Siddiqui

Special Thanks to Dr. Zahid Ahmed Siddiqui

Objectives of Taking This Course

- Not interested, want to just pass.

- Not interested, want to get good grades.

-

Interested want to work in this field.

- For what grade knowledge, you will study this course?

-

How the teachers may help to achieve your target?

- Want to be an inspector, check teachers, check facilities, check neatness, check overall standard etc.

Assignment – 1

- Write and explain your objectives for Steel Structures.

- Search remarkable steel structures from internet, attach photographs and brief description of each, like longest bridge, tallest steel building, etc.

- Types of connections in Steel Structures

- Advantages and disadvantages of Steel Structures

Submission Due Date: 1 week