Engineering Basic Forces

Introduction / Motivation

Have you ever wondered why skyscrapers don’t fall over? Why bridges don’t sink into the rivers they span, or why bicycles are different sizes and shapes? Why are some buildings made of wood and others are made of steel and glass? That’s easy! Because they are made that way right?

Well, how do the people who design things know which material is best to use, how tall a building can be, or even where the best place is to put a bridge? Engineers design structures, such as buildings, dams, airplanes, automobiles, tunnels, chairs, bicycle frames and even toys to hold weight and withstand forces that are placed on them that could tear them apart. So what is a force?

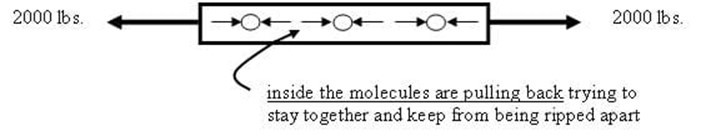

We all know from experience that a force is the amount of pushing or pulling required to move an object. Engineers determine the loads or external forces that act upon a structure. When external forces are applied to a structure, internal stresses (internal forces) develop resistance to the outside forces. The opposition of external and internal forces is what holds the structure together. Once engineers know the loads acting on a structure, they calculate the resulting internal stresses, and design each piece of the structure so it is strong enough to carry the loads without breaking.

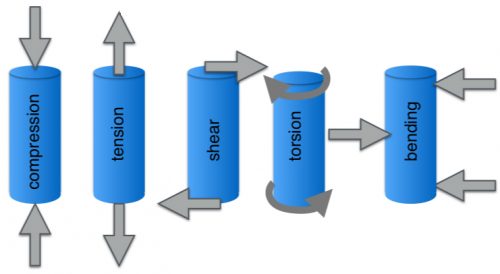

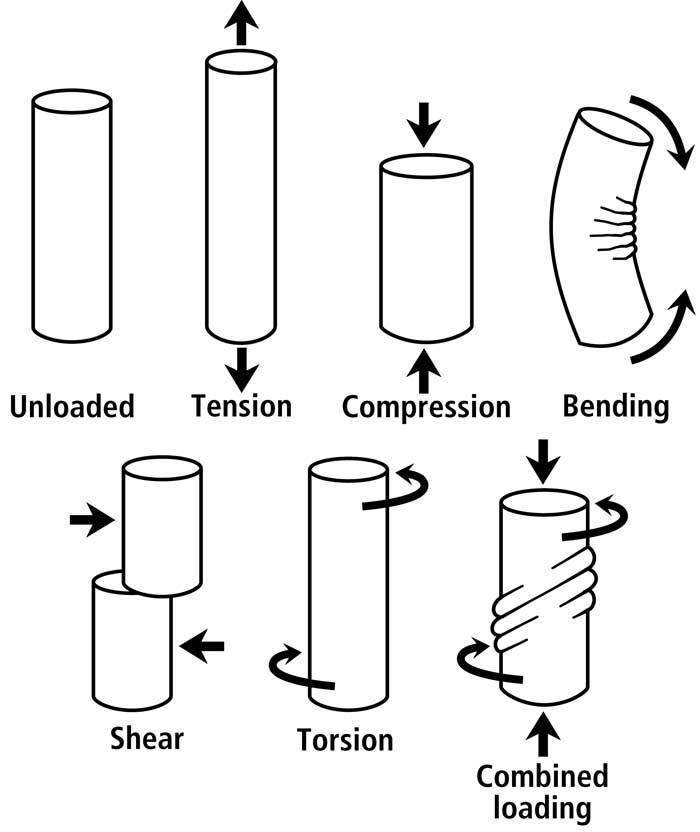

The five types of loads that can act on a structure are tension, compression, shear, bending and torsion.

- Tension: Two pulling (opposing) forces that stretch an object trying to pull it apart (for example, pulling on a rope, a car towing another car with a chain – the rope and the chain are in tension or are “being subjected to a tensile load”).

Figure 1. Tension.

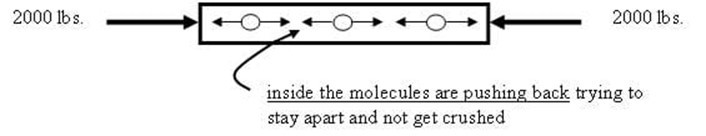

Figure 1. Tension. - Compression: Two pushing (opposing) forces that squeeze an object trying to compress it (for example, standing on a soda can, squeezing a piece of wood in a vise – both the can and the wood are in compression or are “being subjected to a compressive load”).

Figure 2. Compression.

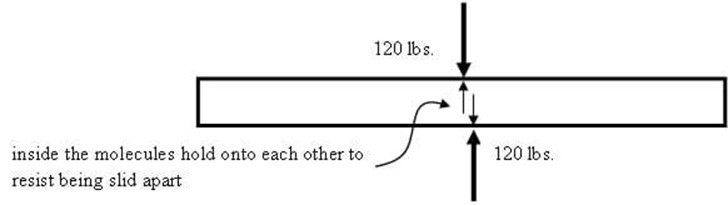

Figure 2. Compression. - Shear: Two pushing or pulling adjacent forces, acting close together but not directly opposing each other. A shearing load cuts or rips an object by sliding its molecules apart sideways (for example, pruning shears cutting through a branch, paper-cutter cutting paper – the branch and paper are “subjected to a shear loading”).

Figure 3. Shear.

Figure 3. Shear.

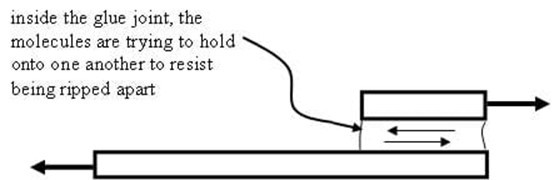

Another example: Pulling on two pieces of wood that have been glued together; the glue joint is “being subjected to a shear loading.”

Figure 4. Shear forces on glued wood.

Figure 4. Shear forces on glued wood.

A Moment of a Force

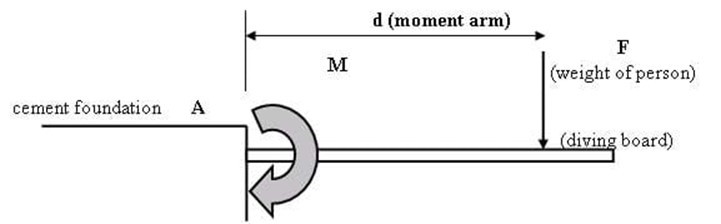

Understanding a moment of a force is key to understanding the last two types of loads. A moment is a “turning force” caused by a force acting on an object at some distance from a fixed point. Consider the diving board sketch in Figure 5. The heavier the person (force), and the farther they walk out on the board (distance), the greater the “turning force,” which acts on the concrete foundation (fixed point).

Figure 5. Moment of a force.

Figure 5. Moment of a force.

The force (F) produces a moment or “turning force” (M) that tries to rotate the diving board around a fixed point (A). In this case, the moment bends the diving board.

The stronger the force, and the greater the distance at which it acts, the larger the moment or “turning force” it will produce.

A moment or “turning force” (M) is calculated by multiplying a force (F) by its moment arm (d). The moment arm is the distance at which the force is applied, taken from the fixed point:

Figure 6: Equation for a moment of a force.

Figure 6: Equation for a moment of a force.

(As long as the force acting on the object is perpendicular to the object.)

If a force measured in Newtons is multiplied by a distance in meters, then the units for the moment are N-m (read “Newton-meters”). If the force is measured in pounds and multiply by a distance in inches, then the units are be lb-in (read “pound-inches”). Units for moments can be any force unit multiplied by any distance unit.

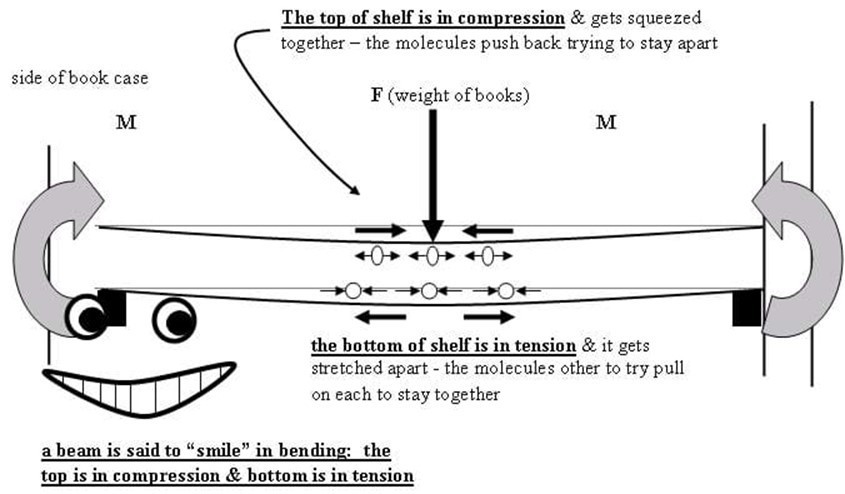

- Bending: When a moment or “turning force” is applied to a structural member that is fixed on both ends, such as a pole beam, making it deflect or bend. A moment that causes bending is called a bending moment. Bending produces tension and compression inside a beam or a pole, causing it to “smile.” The molecules on the top of the smile get squeezed together, while the molecules on the bottom of the smile get stretched out. A beam or pole in bending will fail in tension (break on the side that is being pulled apart) (for example, a shelf in a bookcase, and the earlier diving board scenario).

Figure 7. A bookcase example of bending.

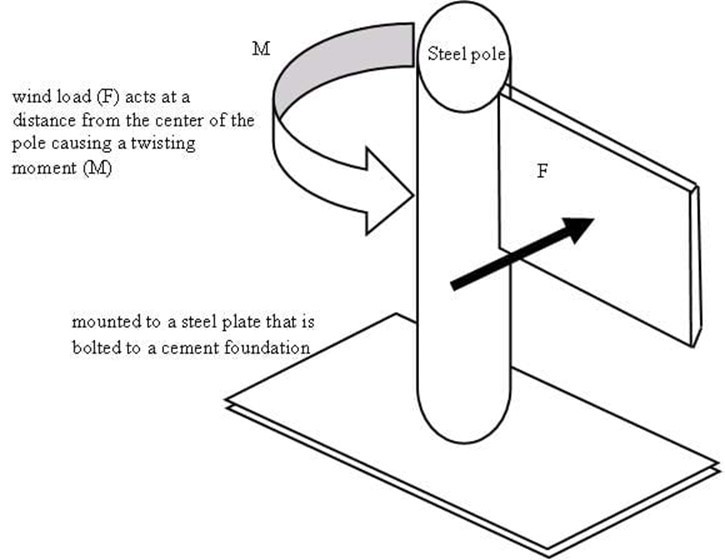

Figure 7. A bookcase example of bending. - Torsion (Twisting): Created when a moment or “turning force” is applied to a structural member (or piece of material) making it deflect at an angle (twist). A moment that causes twisting is called a twisting or torsional moment. Torsion produces shear stresses inside the material. A beam in torsion will fail in shear; the twisting action causes the molecules to be slid apart sideways (for example, a pole with a sign hanging off one side).

Figure 8. Torsion.

Figure 8. Torsion.