Foundation

Spread footings

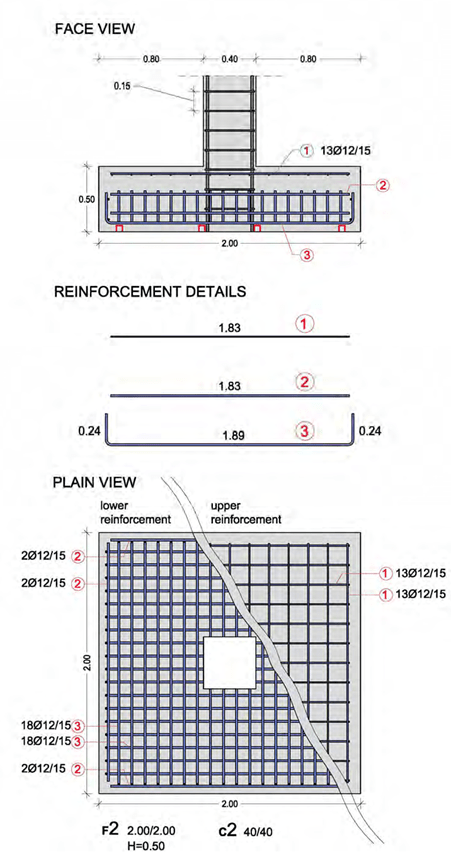

Paragraph 1.2.5 provides all information regarding spread footings. The following example con- cerns a simple spread footing with its footing shaped like a box.

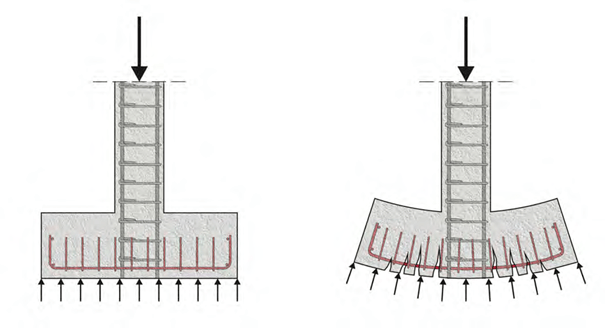

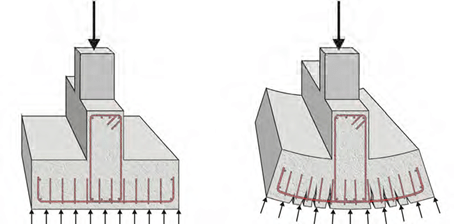

The spread footing behaves like an inverted cantilever with loads applied in the upward direc- tion. As a rule, a spread footing is a quite rigid element therefore, the applied soil stresses are almost linear and in case of a symmetric (with respect to the pedestal) footing, they are or- thogonal. These soil pressures consist the loads carried by the footing which behaves like a slab and is deformed by the way shown at the following figure.

Soil pressures and deformation of an isolated spread footing

The real deformation is in the order of a millimeter and although it is not visible to the human eye, it always has that same form. The reinforcement is placed at the lower surface of the foot- ing both along the x and y axis.

The column rebars can be anchored inside the footing either with a straight anchorage length or with a 90ο hook at their end (resembling a ‘shoe’). The chosen type of anchorage depends upon the footing’s total depth and the level on which the column is considered fixed which is usually the upper part of the adjacent connecting beams. Most of the times, that level is high enough to allow for a straight anchorage length. Practically, the need for hooks at the base of columns arises mainly in the case of a solid raft foundation with a relatively small slab thickness.

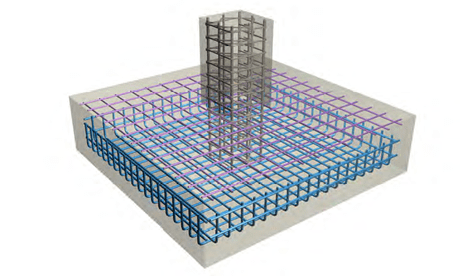

Reinforcement of an isolated spread footing

The reinforcement is the same both for flexible and rigid spread footings either being centrically or eccentrically constructed.

The footing is reinforced with an orthogonal wire mesh that may have horizontal and vertical bars of different diameter and spacing. Bending the rebars ends helps in the proper anchorage of the reinforcement.

According to the Greek regulation, the minimum allowable rebar diameter in a footing is Φ12 and the maximum acceptable spacing between the reinforcement bars is 15cm.

In certain occasions, the footing may have a reinforcement wire mesh both at its upper surface (see following figures).

Spread footing reinforced at the upper and lower surface

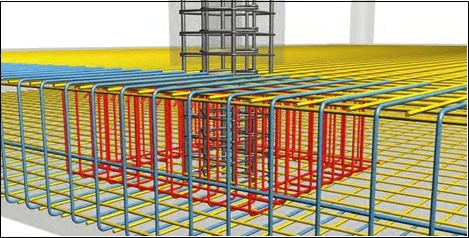

In some other cases, the spread footing may have punching shear reinforcement as well. This reinforcement is usually provided in the form of a peripheral stirrup cage.

Controlling punching shear, with the use of stirrup cages.

Punching shear stresses are similar to the shear stresses (diagonal flexure) and they appear along the perimeter of the col-

Punching shear stresses are similar to the shear stresses (diagonal flexure) and they appear along the perimeter of the col-

umn. Punching shear is a type of column sliding along the side of a cone that forms a 35° angle with the horizontal axis, as shown at the opposite fig- ure. The first stirrup leg must be placed at a maximum dis- tance of 0.5d away from the face of the pedestal and the last stirrup leg at a maximum distance of 1.25d.

Note:

In this specific spread footing,

punching shear is controlled by stirrup cages (figure a) however, it could be also controlled with bundles of properly bent-up rebars (figure b), or with special industrial elements (figure c).

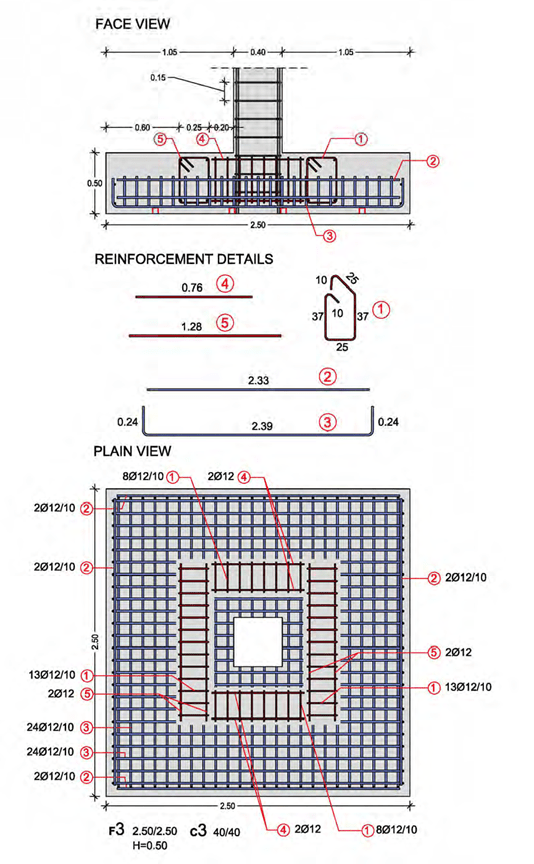

The density and rebar diameters of the reinforcement (punching shear reinforcement included) for the 2.50/2.50 footing with a 40/40 column are given bellow:

Spread footing with punching shear reinforcement

Frame foundation

-

Spread footings without connecting beams (semelles)

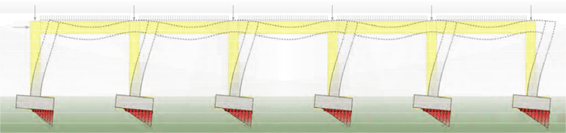

Columns belong to frames i.e. clusters of columns and beams and the behavior of their founda- tion depends upon the interaction between the frames and the soil. It is important to examine the frames’ behavior in relation to the foundation and soil.

The simplest frame consists of two columns, as shown at the following figures:

Two-column frame with centric spread footings

<project: foundation110>

Behavior of a two-column frame with centric spread footings (no seismic loads applied)

When no seismic forces are applied, the soil pressures have a slight trapezoidal form and the spread footing is subjected to severe rotation.

Behavior of a two-column frame with centric spread footings (under seismic loads)

When seismic loads are applied, the two spread footings are heavily over-stressed and they are forced to ‘work’ partially thus leading to large soil pressures. When the earthquake forces shift direction, there is a symmetrical change in the spread footings’ over-stressing.

Notes:

-

In case of an earthquake, a large part of the footing cannot work in the required way. All spread footings have almost the same behavior (boundary spread footings are slightly over-stressed), as shown at the following figure. <project: foundation115>

2. According to the present regulation, the use of spread footing untied by connecting beams is not allowed. However it is useful to know the way they behave, because, in Greece, most buildings constructed prior to 1978 have no connecting beams and there- fore, their possible rehabilitation requires special attention.

-

Spread footings with connecting beams (semelles)

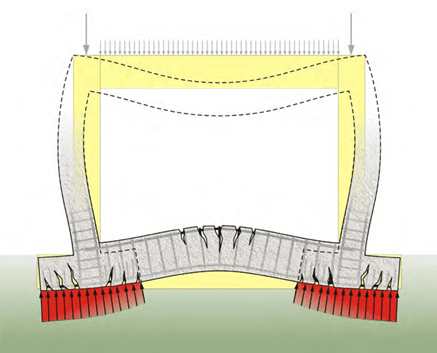

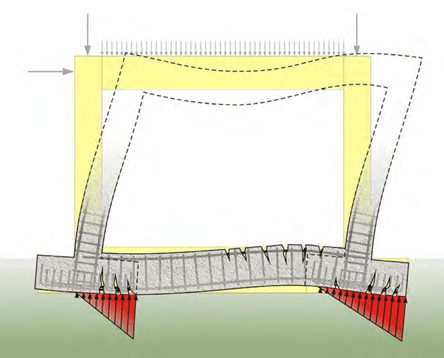

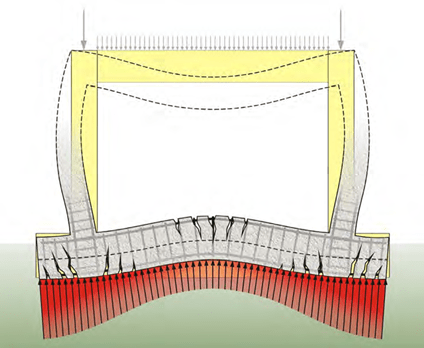

Generally, it is useful to place connecting beams at the foundation because they carry the hori- zontal shear forces and prevent damage from differential settlements. However, in earthquake resistant structures, they are not just simply useful but absolutely necessary because apart from everything else, they centerline the spread footings and secure the fixed support of columns to a high degree. The following figures shown the behavior of spread footings tied together with connecting beams.

Two-column frame with spread footings and connecting beam

<project: foundation120>

Frame’s behavior (no seismic loads applied)

When no seismic forces are applied, the soil stresses have an almost orthogonal form and the spread footings together with the connecting beam are roughly deformed.

Frame’s behavior when the earthquake forces are applied to the +x direction

In the duration of an earthquake, both spread footings work in a satisfactory level. The one is over-stressed thus creating larger soil pressures while at the same time, the other one is re- lieved. When the earthquake shifts direction, the stress conditions reverse. The connecting beam is subjected to large and continuously changing deformation and stresses.

Notes:

-

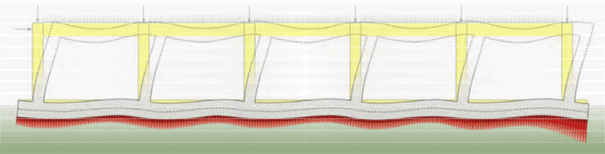

In a multi-column frame with spread footings and connecting beams, the behavior of the former, in a seismic event, is satisfactory. The boundary spread footings are over- stressed (or slightly under-stressed depended upon the earthquake’s direction).

<project: foundation125>

- The earthquake causes reverse stresses in every part of a connecting beam thus applying almost the same flexure at the upper and the lower fiber.

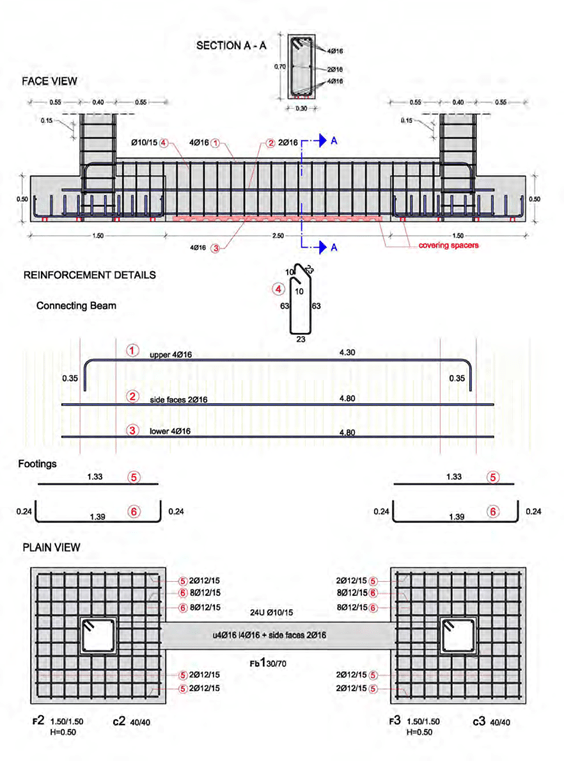

The following figures show the plain view, the elevations and the detailing of the two-column frame foundation reinforcement of the example:

Foundation reinforcement of a two-column frame <project: foundation121>

-

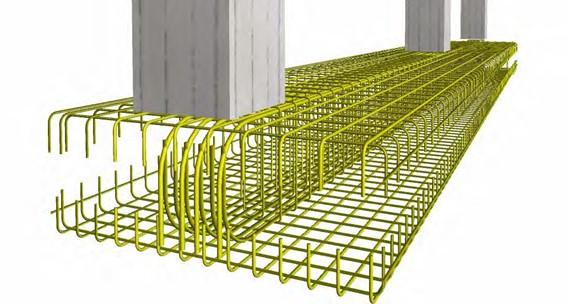

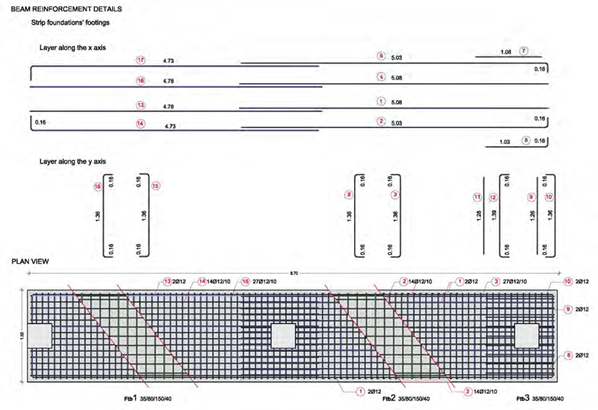

Continuous connecting beam

In case of more than two continuous spread footings and consequently more than one connect- ing beams, the reinforcement follows the same rules mentioned above.

Reinforcement of a continuous connecting beam <project: foundation130>

Extending the footing away from the edge column is extremely useful for the proper behavior of the spread footing (it levels the stress distribution) and therefore, must be aimed when it is con- structional feasible.

Strip foundation

The strip foundation is the foundation element that behaves, simultaneously, like a spread foot- ing and a beam. Strip foundations combine the properties of spread footings and connecting beams.

Two-column frame with a strip foundation that extends (beyond the columns) on both sides

<project:foundation140>

The strip foundation behaves in a way similar to that of spread footings tied together by a con- necting beam. However, due to the fact that the footing and the foundation wall consist a unified body along the entire length of the structure, the systems inertia is larger therefore, its behav- iour is more satisfactory.

Behavior of a two-column frame with strip foundation (no seismic loads applied)

When no earthquake forces are applied, the soil pressures are symmetrically distributed in the entire length of the strip foundation.

The stresses created to the soil are larger in the area of columns.

Behavior of a two-column frame with strip foundation (under seismic loads)

In the duration of an earthquake, one edge is over-stressed thus creating larger soil pressures while at the same time, the other edge is relieved. When the seismic forces shift direction the footings’ over-stressing symmetrically changes. The deformation and stress applied upon the strip foundation are large and continuously reversing.

The footing behaves like a bilateral cantilever (fixed upon the strip foundation’s wall). Its behav- ior is similar to the behavior of the spread footings therefore, it requires reinforcement to its lower fiber, as shown at the figure below.

Behavior of the a strip foundation’s footing

The soil’s reaction, stresses the footing slab in an upward direction. This causes deformations at the lower surface of the footing which are carried by the reinforcement.

Notes:

-

Strip foundations behave extremely well during an earthquake. Depended upon the seismic forces’ direction one edge is heavily over-stressed. In large parts of the strip foundation, the deformation continuously reverses and therefore, it requires strong rein- forcement both at the upper and lower fibre, especially at the first and last opening of a continuous strip foundation. <project:foundation145>

- In order to have a more efficient behavior of the strip foundation’s boundary parts, it is useful to extend the strip foundation beyond the edge columns to an appropriate length.

- Strip foundation with wall and footing

The behavior of this element is quite obvious since the footing distributes the applied loads to the soil, it is stressed by the soil’s reaction and behaves like a cantilever slab while the founda- tion wall behaves in a way similar to a beam.

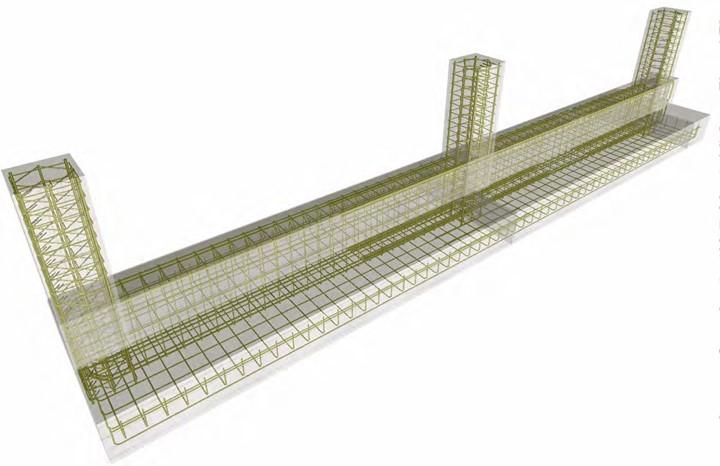

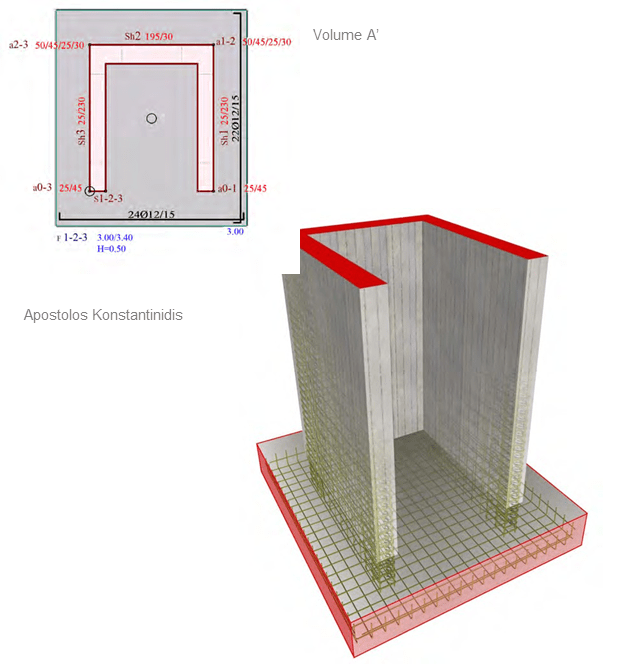

3-D figure of the a strip foundation’s reinforcement

<project:foundation150>

The footing’s reinforcement follows the same rules that apply to isolated spread footings how- ever, its one dimension is of a large length.

The foundation wall reinforcement follows the same rules that apply to connecting beams. Its reinforcement details are analogous to the corresponding reinforcement details of the previously mentioned continuous connecting beam.

-

Strip foundation with a unified wall and footing

In a strip foundation with a unified wall and footing (orthogonal section), the footing’s total depth is equal to the wall’s height.

The only difference between the regular strip foundation and the strip foundation with a unified wall and footing is the fact that the latter requires reinforcement at the footing’s lower surface.

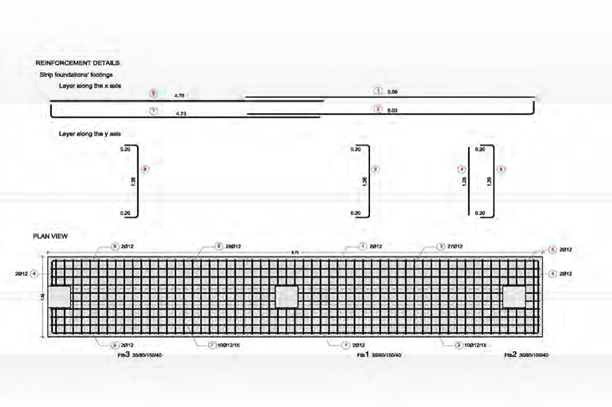

Reinforcement of an orthogonal strip foundation

<project:foundation160>

In the strip foundation where the footing and the wall have the same dimensions a hidden beam is formed. In this specific case, it has a four-legged stirrup while the footing is reinforced with a wire mesh placed both at its upper and lower part.

The footing’s reinforcement follows the rules that apply to isolated spread footings but rebars are placed both at the upper surface.

The wall reinforcement (in the case where the hidden beam is formed), follows the same rules that apply to connecting beams.

The foundation wall reinforcement details of this specific strip foundation are similar to the rein- forcement details of the previously mentioned continuous connecting beam.

-

Strip foundation in which the wall extends beyond the column’s face

Generally, it is useful to place stirrups inside the column and the beam of a joint area that belongs either to the superstructure or the foundation. However practically, this is a strenuous procedure and therefore, it is pre- ferred, in priority order, to place stirrups in- side the columns.

Generally, it is useful to place stirrups inside the column and the beam of a joint area that belongs either to the superstructure or the foundation. However practically, this is a strenuous procedure and therefore, it is pre- ferred, in priority order, to place stirrups in- side the columns.

When the foundation wall extends beyond the face of the column, additional vertical re- inforcement is required. This reinforcement may be provided in the form of regular stir-

rups or additionally fitted stirrups in the shape of a hairpin, as shown at the following figures.

The column with 80/25 section, in the common wall of

the building, is partially sited upon the strip foundation that has a wall of 35/80.

1st example: one-sided extension of the foundation wall

1st example: one-sided extension of the foundation wall

After the implementation of the stirrup cages inside the strip foundation walls, the wall’s part that extends beyond the column remains un-reinforced along the vertical axis. The hairpin bars (in red colour) that will be placed in that area are shaped and placed in a separate phase.

Strip foundation that extends beyond the column

The vertical reinforcement positioned at the common area between the foundation wall and the column, is comprised of hairpin bars placed afterwards one by one.

In that area, the vertical reinforcement at the back side of the strip foundation is provided by the column’s longitudinal reinforcement (i.e. from the column rebars).

Wall reinforcement of a strip foundation, that extends beyond the column, with additional hairpin bars

The ends of the hairpin bars may have a straight length or they may be bent in the form of a hook, depended upon which of the two is more feasible (see relevant note).

2nd example: two-sided extension of the foundation wall

2nd example: two-sided extension of the foundation wall

The 80/25 column is sited upon the center of the strip foundation wall. The strip foundation and the foundation wall have sections of 50/80 and 35/80 respectively.

After the implementation of the stirrup cages inside the strip foundations’ walls, the wall parts that extend beyond the column remains un-reinforced along the vertical axis. The double hair- pin rebars (in red colour) that will be placed in that area are shaped and positioned in a sepa- rate phase.

The ends of the hairpin bars are formed with a straight length

The vertical reinforcement positioned at the common area between the foundation wall and the column, is comprised of bilateral hairpin bars positioned one by one on both sides of the beam.

In this specific example, the stirrups placed inside the strip foundations’ wall are four legged and after the cages’ implementation the outer part of the wall, in the column area, remains without vertical reinforcement. The inner transverse reinforcement (the 2 middle legs of the 4 legged stirrups) in that specific area of the foundation wall is provided by the column rebars.

Vertical reinforcement placed inside the wall of a strip foundation that extends, beyond the column, on both sides

Notes:

Notes:

-

There is no need to mention that in order to assemble any of the previously mentioned reinforcements, the formwork must not be constructed until after the comple- tion of the reinforcing.

-

If there is access to those specific parts of the strip foundation, it is useful to form the hooks at the ends of the hairpin bars either during their shaping or after their implementation.

-

The next figure shows a combination of prefabricated hooks and proper fitting after the rebars’ implementation. The 90ο bend can be achieved by means of a special bending tool by the steel fixer.

Raft foundation

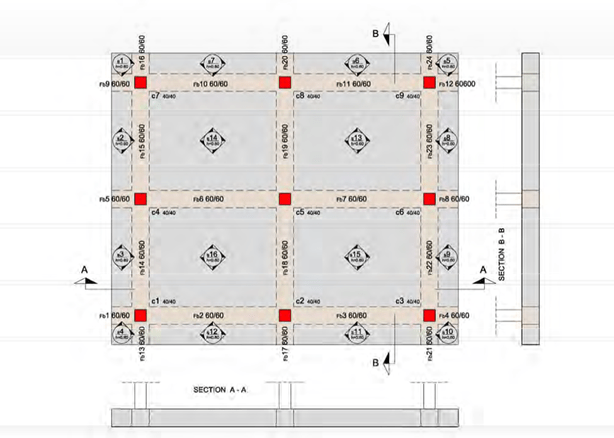

The extensive foundation (which is usually called raft foundation), is a unified foundation that extends throughout the entire area of the columns.

Raft foundation

As a rule, raft foundation is used as a building’s foundation when the soil has a low bearing ca- pacity.

The behaviour of the raft foundation resembles the behaviour of a strip foundation grate.

Form of soil pressures in a raft foundation

The stresses applied upon the soil are larger in the columns’ area and lighter in the intermediate areas. The presence of beams acting as stiffeners helps in a more even distribution of the soil pressures between the columns’ areas and the intermediate areas of the raft foundation.

The raft foundation may belong in one of the following four general categories, (1) ribbed raft foundation, (2) solid raft foundation, (3) raft foundation with hidden beams, (4) mixed raft foun- dation.

-

Ribbed raft foundation

Ribbed raft foundation

In a ribbed raft foundation apart from the unified foundation slab there are also beams which behave as stiffeners. The beams add stiffness to the foundation and apart from everything else, they level the soil stresses.

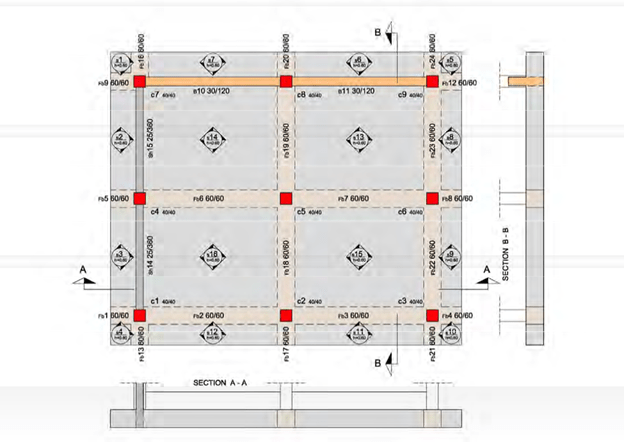

Unified foundation slab (raft foundation) with stiffeners (beams)

<project: FoundationRough10>

The formwork’s assembling and the reinforcement implementation of a raft foundation stiffened by beams are two relatively strenuous procedures.

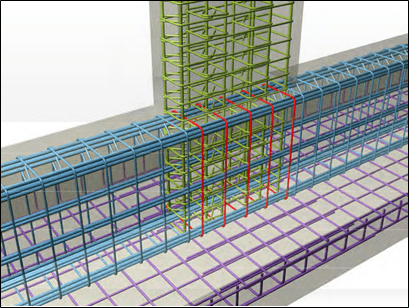

As shown at the following figure, the ribbed raft foundation reinforcement can be separated into three categories:

- slabs’ reinforcement (in yellow color)

- slabs’ free edges reinforcement (in blue color)

- slabs’ free edges reinforcement (in blue color)

- beams’ reinforcement (in green color) The column rebars are in grey color.

Reinforcement of a ribbed raft foundation

The foundation slabs are reinforced with two wire meshes, one placed at the lower fibers and one at the upper fibers, by following the reinforcement rules that apply to slabs.

The beams are reinforced with strong stirrups and bars placed both at the upper and lower fi- bers, by following the reinforcement rules that apply to beams.

The slabs’ free edges are reinforced with common hairpin bars or with a wire mesh folded like a hairpin, by following the reinforcement rules that apply to slabs.

Note:

A foundation grate can be stiffened either by beams or by walls. In the latter case, the rein- forcement of the foundation slab does not depend upon the wall’s reinforcement.

-

Solid raft foundation

The unified solid raft founda- tion is the most simple founda- tion form and its formwork as- sembling as well as its rein- forcement implementation do not require hard labor.

Solid raft foundation

In the solid raft foundation, there is only one unified foundation slab.

The foundation slabs are reinforced with two wire meshes, one placed at the lower fibers and one at the upper fibers. Since the most intense stresses appear along the columns’ axis, their surrounding areas are usually reinforced with stronger or double grates.

The slabs’ free edges are reinforced with common hairpin bars or with a wire mesh shaped like a hairpin.

Notes:

-

On a practical level and mainly when using a folded wire mesh as a free edge’s reinforcement, the hairpin re- bars are positioned in the 2nd phase, as shown at the first figure.

The alternative solution for providing the free edges’ reinforcement includes the formation of hooks at the ends of the upper and lower rebars as shown at the second figure. This solution compared to the hairpin solution, apart from everything else, has a higher shaping-cost but mainly it lacks a natural peripheral rebar chair.

The alternative solution for providing the free edges’ reinforcement includes the formation of hooks at the ends of the upper and lower rebars as shown at the second figure. This solution compared to the hairpin solution, apart from everything else, has a higher shaping-cost but mainly it lacks a natural peripheral rebar chair.

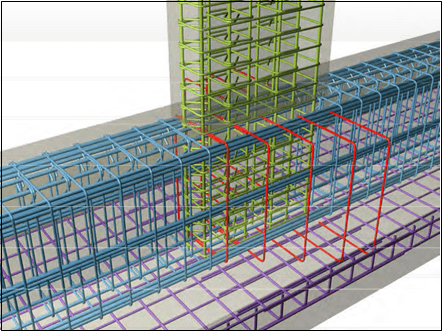

The reinforcement of a solid raft foundation can be separated into three categories, as shown at the following figure:

- slabs’ reinforcement

- slabs’ free edges reinforcement

- slabs’ free edges reinforcement

- punching shear reinforcement (when necessary) in the area surrounding certain columns (in red color)

The column rebars are in grey color.

Reinforcement of a solid raft foundation

The punching shear reinforcement, when it is required, is similar to the one used in the isolated spread footings of paragraph 3.7.1, as shown at the following figure.

Raft foundation with punching shear reinforcement

When the columns are subjected to large loads and the foundation slab’s thickness is analogi- cally small, it is obligatory to use punching shear reinforcement. That reinforcement can be pro- vided by stirrup cages, as it is in this example, by bundles of properly bent rebars or by special industrial elements.

-

Raft foundation with hidden beams

In a raft foundation with hidden beams, the foundation slab is unified and has no additional stiffeners. This means that geometrically, it is as sim- ple as the previous case.

Its formwork assembling does not re- quire a lot of effort as opposed to its reinforcement implementation.

Raft foundation with hidden beams <project: FoundationRough20>

The reinforcement of the raft foundation with hidden beams is the same with the reinforcement placed inside the ribbed slab foundation. The only difference lays in the fact that the total depth of the beam-stiffener is equal to the slab’s thickness.

Reinforcement of a raft foundation with hidden beams

The stirrups placed inside the hidden beams may be two-legged or four-legged (as they are in this example). On other occasions, stirrups with more than four legs can be used.

-

Mixed raft foundation

The mixed raft foundation is an extensive foundation which is partially stiffened by beams or by walls.

Mixed raft foundation

<project: FoundationRough40>

This specific raft foundation includes solid parts, parts stiffened by beams and parts stiffened by walls.

The formwork assembling and the reinforcement implementation of a mixed raft foundation in- volve a lot of difficulties however, sometimes, it is an unavoidable solution e.g. in basements where it is obligatory to have shear walls.

Foundation cases

-

Foundation of composite elements

The composite elements, in the case of spread footing foundation, require one unified spread footing.

In order to comprehend the reinforcement of composite elements, the following sections regard the reinforcement of the unified footings used in the two characteristic examples of paragraph 3.3

Elevator

Staircase

In the case where the foundation of the staircase is composed of a unified spread footing, due to its extremely extensive surface, it is required to place a double reinforcement grate (at the upper and lower surface).

Vehicle ramps on ground

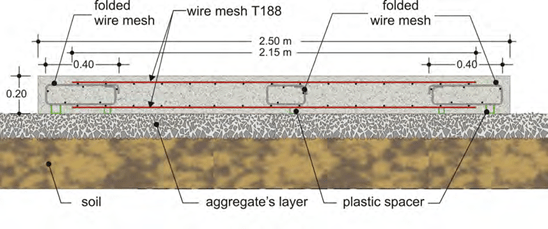

The vehicle ramp on ground is an extensive load bearing element which at the same time con- stitutes its self-foundation. As in every other foundation, the soil condition has a fundamental importance and most of the times in ramps’ case, it is formed at least partially with embankment (polder).

Most of the times, no matter how much effort has been put to the proper compaction of the em- bankment, there is uncertainty about its homogenous future behavior, as shown at the following figures.

The first case of a floor’s unfavorable behavior is the subsidence (recess) of the soil under the middle of the ramp’s width and the formation of tensile stresses in the lower fibers

[the deformations shown at the above and the following figure are presented in a large scale].

The second case of a floor’s unfavorable behavior is the subsidence of the soil under the one or the two ramp ends and the formation of tensile stresses in the upper fibers.

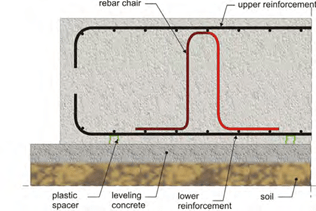

In these cases, the ramp must be reinforced with a double wire mesh, one placed at its lower surface and at its upper surface.

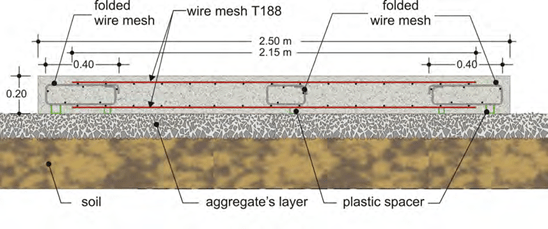

Prior to the ramp’s reinforcement implementation one should ensure a level and properly com- pacted surface. This can be achieved either with the use of a thin concrete layer (3 to 5 cm), or with the use of gravel or with 3Α and proper compaction.

Usage of aggregates for the formation of the ramp’s substrate allows the application of plastic spacers however, these must be positioned upside down so as to avoid sinking inside the sub- strate.

In order to provide the reinforcement with two wire meshes, it is mandatory to use rebar chairs.

For ramp widths reaching up to 2.5m and since there it is possible to cast and vibrate concrete from both sides of the ramp, rebar chairs can be replaced by open-form folded wire meshes (hairpins) or by closed form folded wire meshes which at the same time will provide efficient co- hesion of the ramp’s edges.

A combination of reinforcement, support and lap-splicing of a standardized wire mesh Τ188 (Φ6/15 with dimensions 2.15×5.0 m)

Notes:

-

In case of an extremely well-formed substrate, it is allowed to use only a single wire mesh which will be placed for example at the 2/3 of the ramp’s thickness.

-

In a ramp, stresses can be created in both directions; therefore, always assuming the same behaviour, the placed wire mesh is usually of a square shape. The wire meshes used for the ramp’s reinforcement must be normally lap-spliced (in usual cases a length of 2 up to 3 openings is enough).

-

Heavy-duty ramps require edge reinforcement as well. That reinforcement can be also used as rebar chairs.

-

The edge behavior does not appear only to the ramps’ edges but also to the areas around joints. The joint edges are treated by the same way as the side edges. It is useful to place the joints in the shortest possible distances e.g. every 15 meters.

Extended slab on ground

Extended building slabs on ground, are mainly floors constructed upon the upper basement af- ter the foundation’s embankment (polder).

The slab on ground is an element analogous to the ramp on ground and their behavior is almost alike. The reinforcement is implemented with the same way however, it involves an additional difficulty that arises due to the extended slab’s surface which in the case of a double wire mesh creates problems in both the reinforcement implementation and the concrete casting.

Notes:

-

The problem of securing the double wire mesh’s proper position at the upper and lower parts of the slabs is not that intense in the superstructure because: firstly, there are the beams that separate and support the slabs’ reinforcement and secondly, the reinforce- ment of the slabs is strong and therefore, carries effectively not only its self weight but also the loads applied by the movement of the personnel responsible for the steel fixing and the concrete casting.

-

The solution to this problem is (a) a well-formed surface with fine aggregates properly compacted, or an additionally casted thin layer of concrete (3 to 5 cm) and (b) usage of narrow spaced rebar chairs (with practices similar to those mentioned in paragraph 2.6.1)

-

A larger live load, applied upon the slab, requires the use of a stronger wire mesh.

4. Generally, the standardized wire mesh with square openings like Τ196(#Φ5/10) and T188(#Φ6/15) of steel class B500A [table 2], presents a satisfactory behavior under the common loads applied upon basements’ slabs.