Staircases

Staircases appear in a number of forms and behave in different ways, as shown at the following figures: simply supported (pinned on both sides, fixed on one side, fixed on both sides), cantile- ver, winder, helical, etc. The following paragraphs examine the reinforcement of the most com- monly met staircases which are the orthogonal and the winder stairs.

Simply supported staircase

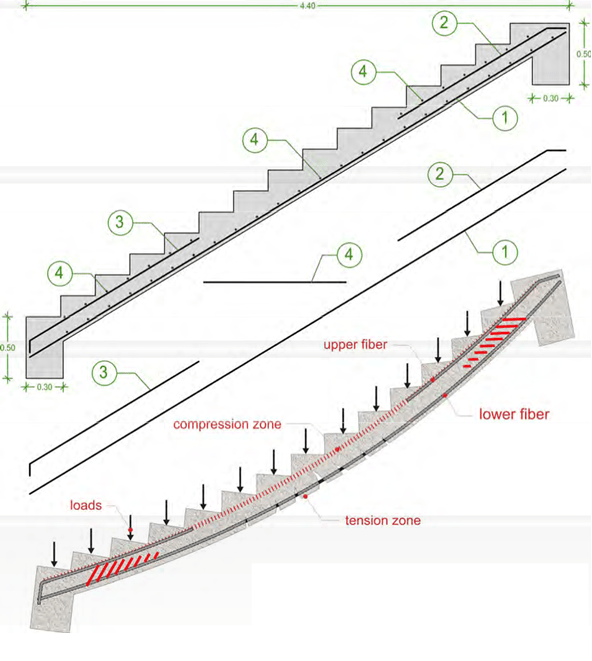

A simply supported staircase behaves similarly to the simply supported slab mentioned in para- graph 3.5.1

Simply supported staircase continued by slabs

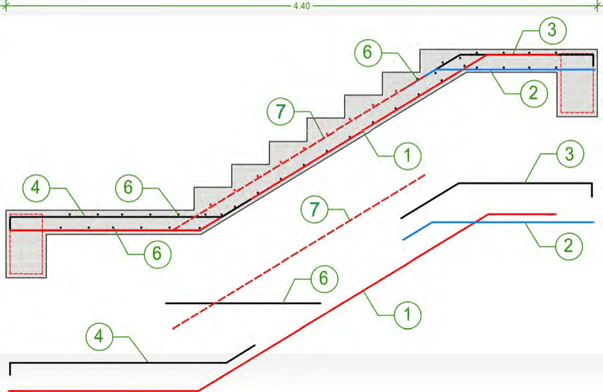

Due to the continuation of the staircase by slabs at its base and top, bending moment is formed in the supports (up- per fibers) and therefore, rebars are required both at their upper fibers.

Note:

In most occasions, staircases are continued by the floors’ slabs, as in the previous example; therefore, they contribute to the seismic diaphragmatic behavior of the floors’ slabs. During an earthquake, slabs sway only along their horizontal plane and consequently they are not stressed by additional flexure. On the other hand, the staircases, due to their slope, transfer the diaphragms’ seismic forces to the columns. This subjects them to deformation transverse to their plane which causes the formation of seismic flexural moments. All the above show that staircases behave like slabs when vertical loads are applied upon them and like beams when they are stressed by earthquake forces. Since the seismic loads continuously shift direction, the applied earthquake stresses constantly appear reversely therefore, staircases require rein- forcement both at their upper and lower fibers. Most of the times, due to the fact that the accu-

rate estimation of the staircase’s exact behaviour includes a large number of uncertainties, it is preferred to place reinforcement along the entire length of both its upper and lower surface (re- bars 7).

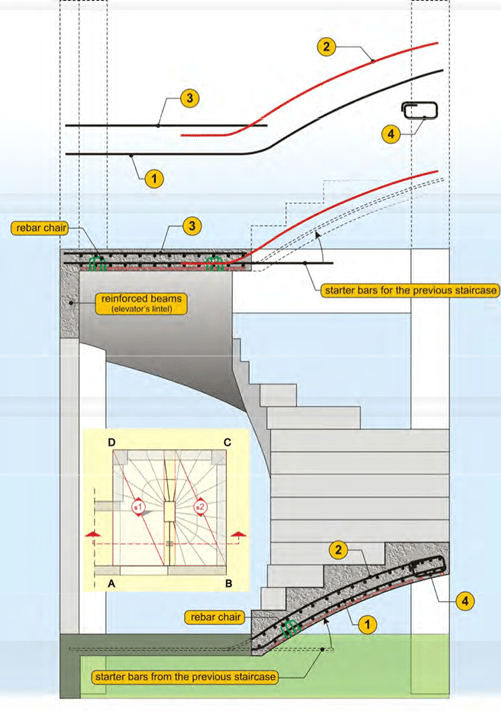

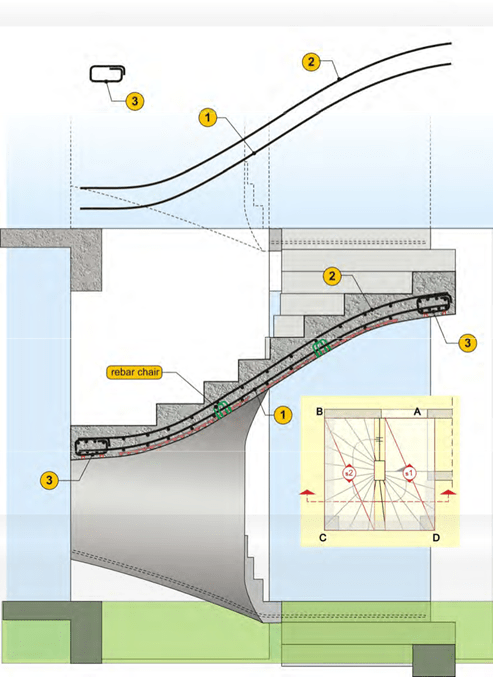

Starter bars in staircases

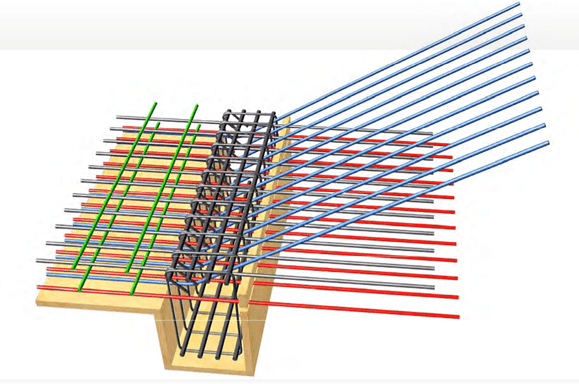

A staircase connects two subsequent floors therefore, it cannot be monolithically casted with them since the formwork and the reinforcement implementation as well as the concreting are done firstly at the subjacent floor and after a few days at the superjacent floor. The most usual way to construct a staircase12 is together with the superjacent floor. However, in order to achieve a connection with the subjacent floor there must be properly placed starter bars. More- over, starter bars must be positioned and at the superjacent floor for the staircase of the next level.

The following describe the practice followed for the positioning of starter rebars in the subjacent and the superjacent floor.

Starter bars at the base of a staircase

The landing reinforcement is extended towards the direction of the staircase for the next floor whose formwork and reinforcement implementation as well as its concrete casting will be car- ried out in a following phase of the construction.

The proper position of the starter bars is secured between thin formwork strips.

12 The most practical and economical method is the use of a completely prefabricated reinforced concrete staircase fitted inside the structural frame. In earthquake resistant structures, the staircase is an element strongly affected by the seismic forces therefore, the installation of a pricast staircase in an already constructed structural frame is a sensitive task. It requires special attention in order to provide an adequate support and accurately predict the effect that its installation will have to the structure. The precast staircase can be installed upon the load bearing system either after the frame construction of both two floors, supported by special starter bars, or during the construction of the super- jacent floor, supported by starter bars fitted only to the subjacent floor.

The starter bars are bent at the proper angle prior the staircase’s planking

Before the positioning of the staircase’s formwork (planking), the starter bars are properly bent at the necessary height (of course they could be implemented as already bend-up bars how- ever, this entails accuracy difficulties).

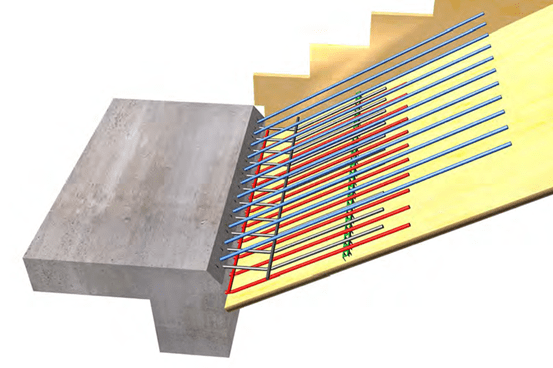

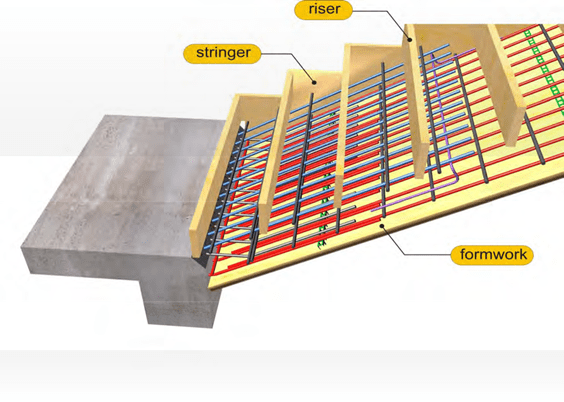

The formwork and reinforcement of a staircase around the area of the starter bars

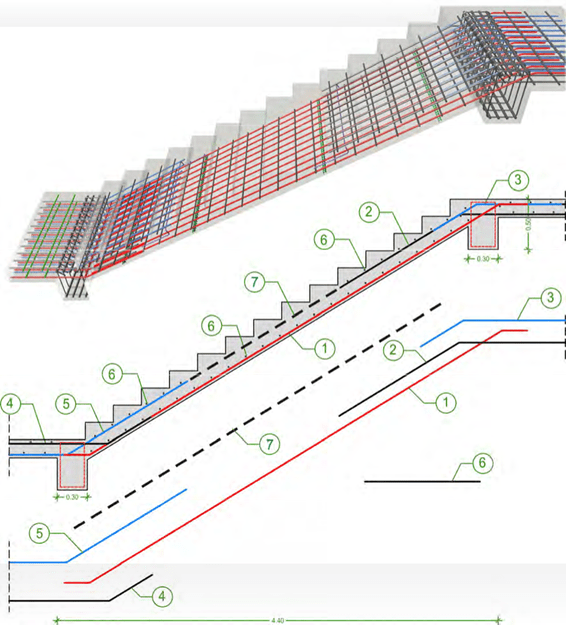

During the final phase of the staircase’s reinforcement implementation, the lower rebars (in red color) are wired to their proper position with the distribution bars. The next phase includes the positioning of any necessary additional upper rebars followed by the placement of their distribu- tion bars. The stringers and the risers are placed last.

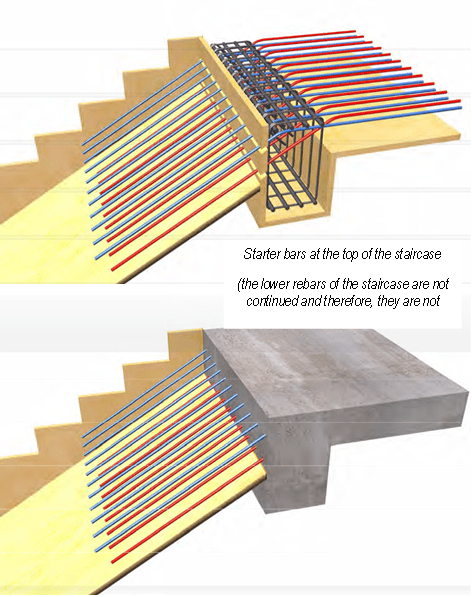

At the top part of the staircase, the reinforcement is normally implemented based on the fact that the staircase will be monolithically casted with the slabs-beams of the floor. Generally though, it is necessary to place starter bars for the next staircase.

Note:

In the special occasions where the staircase will be constructed in a following phase, starter bars are left at the top part of the staircase according to the following details13:

The staircase that will be constructed in a following phase will be supported upon those starter bars and the starter bars of the lower floor.

13 In the case where the stair ends to a slab instead of a beam, it is recommended to construct a reinforced zone in that area. The starter bars will remain the same and the slab’s lower rebars will be extended “waiting” to be anchored

Staircase with landings

The flights of the orthogonal staircases are not always straight. On the contrary, most of the times they are polylines with successive sloped and horizontal segments. The following exam- ple shows a typical staircase with landings into which most cases are reduced.

When the staircase contributes to the seismic diaphragmatic behavior of the floors (as is the rule), it is recommended to use negative rebars as well [dashed bar (7)]

Notes:

The negative rebars, apart from everything else, help in the proper concreting of the staircase’s sloped flights because they retain the wet concrete in a sat- isfactory degree.

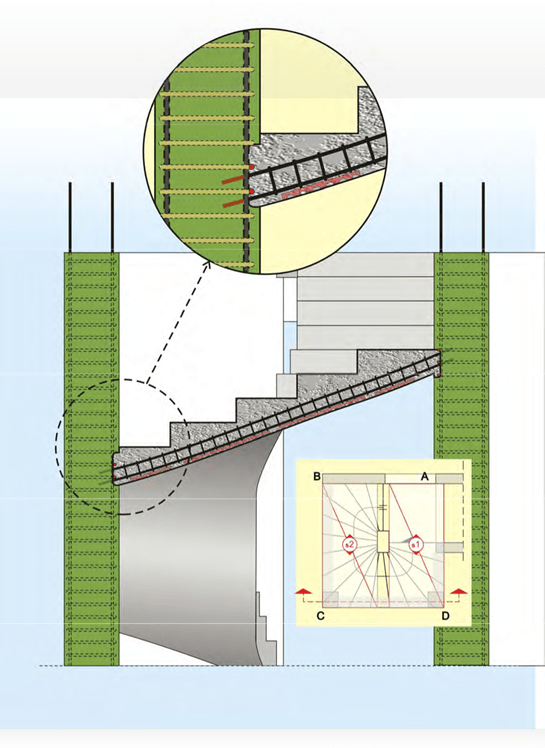

A good solution in order to cover the needs for (a) distribution rebars of the lower reinforcement, (b) free edges’ hairpin bars and (c) rebar chairs, is to use the unified bars shown at the next figure.

Another solution for the combination of these three requirements is the use of the upper reinforcement’s distribution bars. This solution provides stronger re- bar chairs.

Lower distribution rebars – free edges hairpin bars and rebar chairs, with a single bar

Upper distribution rebars – free edges hairpin bars and rebar chairs, with a single bar

Winder staircase

As a rule, in small buildings for space economy, the staircase is constructed with winder steps therefore; practically it does not have level but crooked flights.

These flights, for a less strenuous reinforcement implementation, are considered to be level and are reinforced by following rules similar to those regarding straight staircases.

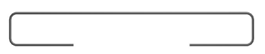

Every flight is reinforced separately from the other however, constructional they intersect. The two primary flights which are sited upon two opposite beams (sections 1-1 and 2-2) are firstly reinforced then follows the reinforcement of the secondary vertical flights.

In space-economical winder staircases, the supports’ distances between the columns are rela- tively short therefore; there is no need to construct beams as well. This happens because, apart from the technical difficulties that it involves, it leads to the formation of extremely strong short columns which are particularly dangerous during an earthquake. An efficient simulation of the static behavior can be achieved by using reinforced zones between the supports from column to column or from beam to column and then to reinforcing the primary and secondary staircase flights, as shown at the following example.

PLAN VIEW

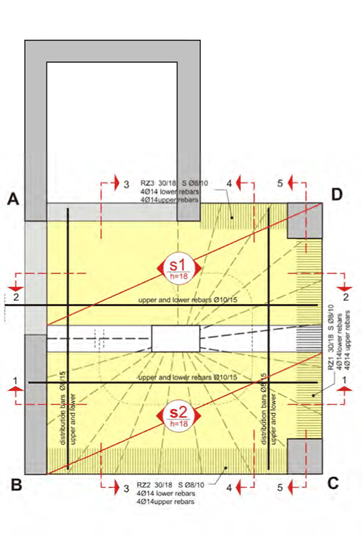

SECTION 1-1

The support of the staircase upon the shear wall can be achieved by various ways based on the designer’s simulation and the dominate practices. Some of the support options are presented below:

-

Simultaneous reinforcement implementation and concrete casting of both the staircase and the shear wall. Theoretically, this is the most effective solution however, it involves large con- structional difficulties and therefore it is not usually chosen.

-

Positioning of starter bars (3) and (4) during the shear wall’s construction. This practice is being followed in the above example. It is recommended to place the starter bars by the way explained in §3.2.7, in short height though.

-

Positioning of starter bars (3) and (4) during the shear wall’s construction, without the forma- tion of a ‘nest’.

-

Positioning of starter bars (3) and (4) after the shear wall’s construction, by drilling holes and resins usage.

-

Fitting of special supports upon the shear wall, for the formation of specific support condi- tions e.g. pin support.

-

Avoidance of anchorage into the shear wall by forming a reinforced zone parallel to it (this zone is, either way formed by the distribution reinforcement). Of course, in any case, the longi- tudinal reinforced zone RΖ2 must be properly anchored upon the shear wall.

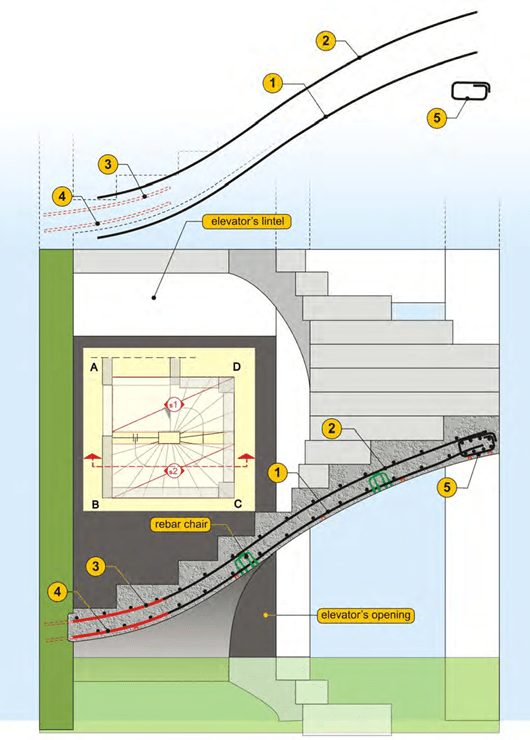

SECTION 2 – 2

SECTION 3 – 3

The reinforcement zone along the secondary direction of the staircase’s support, could be ne- glected however, as a slab’s free edge, it would require hairpin reinforcement (see § 2.6.1). The difference in labor cost and used materials between those two options is not significant. The use a reinforced zone with the upper and lower reinforcement enhances the ductile behavior of the staircase.

Due to the large section width of the staircase, the shear strength is usually satisfactorily high therefore, usage of open-form stirrups-rebar chairs is acceptable. Of course, it is more effective for the stirrups to be properly closed with hooks bent at 135ο.

SECTION 4 – 4

In winder staircases, extra attention must be paid to the horizontal area between the flights both during the design and the planking of the staircase so as to ensure that the staircase’s thick- ness (vertical to the planking) is equal to the thickness of its outer flight. Then it will be feasible to secure the proper positioning of the upper reinforcement grate with rebar chairs of equal height. These rebar chairs can be four-legged industrial produced, wiggly impromptu created or handmade hairpin bars placed at the distribution rebars ends.

SECTION 5 – 5

When the staircase is supported upon a column, the applied rules are the same with those men- tioned above regarding the staircase’s support upon a shear wall.

Either there are starter bars or they are fitted afterwards with resins, the bars of the reinforced zone are placed as unified pieces. Since, as a rule, the outer flight is smooth, it can be rein- forced with bars of a larger diameter compared to those used in the staircase.

Generally, the smaller the diameter of the staircase rebars is, the less strenuous is the shaping of the bars’ various parts.

Notes:

-

If the masonry filling at the area surrounding the staircase is considered to be rigid, the con- struction of reinforced zones, in the secondary flights of the staircase, enhances the ductility of the surrounding area. This, in the case of an earthquake, helps to the cracking avoidance in both the staircase and the filling walls (behavior analogous to a bonding beam).

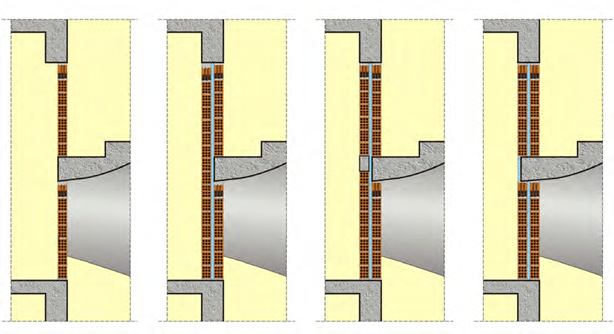

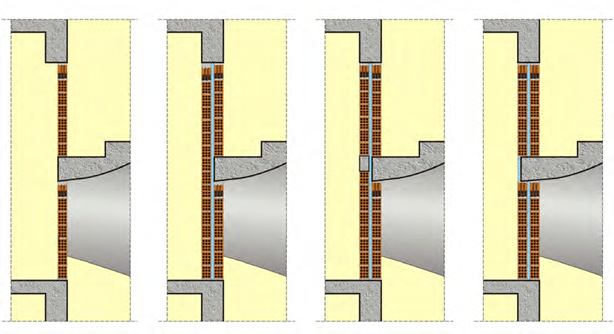

- Extending the staircase under the floors’ beams is not mandatory however, when it is done is ensures a more effective staircase reinforcement and a better brick fitting. The following figures show 4 cases where the stair is extended under the beams:

- Masonry stretcher bond without thermal insulation

- Double stretcher bond with thermal insulation

- Double stretcher bond with thermal insulation

- The same as (b), with an additional bonding beam at the free wall

- Extension of the staircase to the entire wall thickness and a thermal insulation strip placed to the staircase’s end

(a) (b) (c) (d)