Bitumen Production Methods

Four different methods are used to produce petroleum bitumen including:

- Distillation (Straight Run)

- Air Blowing

- Deasphalting

- Blending

In this post we will clarify each of these methods for you.

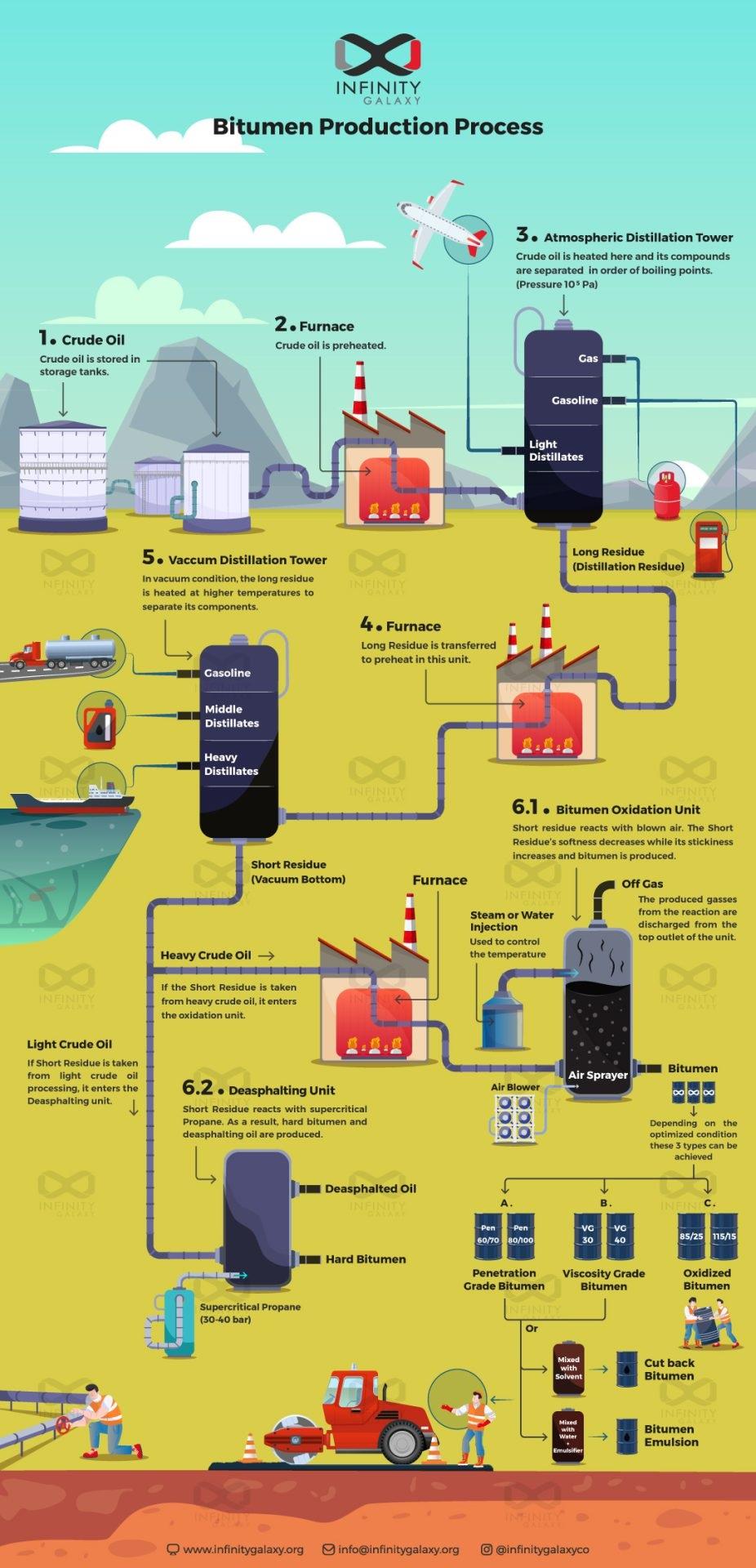

Distillation (Straight Run)

Bitumen is mainly obtained from the distillation of crude oil.

Two different types of distillation towers are used in this process:

- Atmospheric Distillation Tower

- Vacuum Distillation Tower

First, crude oil is heated in the atmospheric distillation tower at a temperature of 300 to 350 °C. In this situation, light oil components that have a low boiling point are removed from the upper part of the tower .The residual of the end of this tower is known as the Atmospheric Residue.

In the continuation of the distillation process, the atmospheric residue is transferred to the vacuum distillation tower.

This is done to prevent the thermal cracking of molecules and remove the last trace of light fractions. Under vacuum conditions , the pressure drop causes the boiling temperature to decrease and each light component to separate.

The residue of this tower is called the vacuum bottom. The vacuum bottom is usually a hard material that can be used directly.For this reason, it is called straight run bitumen.

But sometimes the bitumen coming out of the vacuum tower does not have proper physical properties and its properties must be modified, which is called straight run bitumen.

Air Blowing

Air Blowing is the main way to produce bitumen. Air blowing is used when the feedstock does not have the expected properties.

In this process, the air is blown into the bitumen with a flow rate of 85 to 140 cubic meters per minute at a temperature of 280 degrees Celsius.

The purpose of air blowing is to harden bitumen and change its physical properties for different applications.

Infinity Galaxy, as an international bitumen supplier, has prepared the following infographic for you to know more about the air blowing process.

Air Blowing is done in two ways, Air Rectification and Fully Air.

- Air Rectification

The air rectification method is used to adjust the physical properties of bitumen, such as reducing penetration and increasing softening point and viscosity.

Air rectification is performed in two ways: Continuous Blowing and Batch Blowing.

The difference between the two batch and continuous methods is in the way of blowing air.

In the continuous process, the vacuum bottom enters the blowing tower with a constant flow rate. After blowing the air, the bitumen is continuously discharged from the air blowing tower.

Meanwhile, in the batch blowing method, the blowing tower is filled with a certain volume of feedstock. Blowing air occurs under certain conditions. When the product reaches the desired specifications, the tower is discharged.

In a continuous process, more bitumen is produced per unit of time than in the batch method.

- Fully Air Blowing

In the fully air blowing method, also known as oxidation, more air is passed through the feedstock than in the air rectification method.

By increasing oxidation, final products with different penetration and viscosity are produced.

In this process, by controlling the reaction variables, oxidized bitumens with specific physical and chemical properties can be prepared. For example, chemical reactions lead to an increase in the apparent molecular weight and polarity of bitumen which can affect the adhesion property of bitumen in bonding the aggregates to each other. These bitumens can be widely used in roofing applications.

Deasphalting

One of the methods of bitumen production is solvent deasphalting.

In this method, bitumen is separated from crude oil by using propane or butane solvents. The vacuum bottom is mixed with propane (butane) and then de-asphaltene oil is extracted from it.

Depending on the solvent used in the process, asphaltene and petroleum resins are among the residual products produced by the deasphalting unit.

The operating technique used in the deasphalting unit and the type of crude oil processes play an important role in determining the characteristics of the bitumen produced.

Blending

One of the methods of bitumen production is the blending process. In this method, bitumens with different physical properties are mixed.

In the blending process, specific ratios of bitumen with higher viscosity are mixed with bitumen of lower viscosity to produce bitumen with specific characteristics.