plastic

POLYMER : The word polymer literally means ” many parts “. that contains many chemically bonded parts which themselves are bonded together to form a solid.

Two industrially important polymeric materials are:

- Plastics

- Elastomers

Plastic is a synthetic material made from a wide range of organic polymers such as polyethylene, PVC, nylon, etc., that can be moulded into shape while soft, and then set into a

rigid or slightly elastic form.

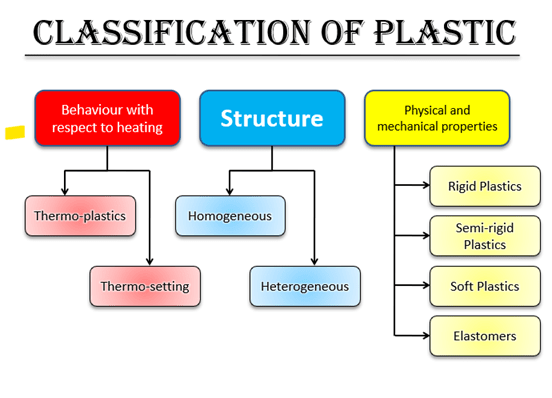

There are many ways of classifying plastics. They can be classified considering various aspects, as according to their:

- Behaviour with respect to heating,

- Structure

- Physical and mechanical properties.

Themoplastic & thermosetting

| THERMOPLASTICS | THERMO-SETTING PLASTICS |

|

Thermoplastics variety softens by heat and hardens when cooled down. It can be used by remolding as many times as required. |

Thermosetting plastics can not be reused .This variety requires a great pressure and momentary heat during molding which hardens on cooling. |

Thermo-plastics

PROPERTIES

- Allow plastic deformation when it is heated.

- They are brittle and glossy.

- They are soluble in certain solvents.

- Swell in the presence of certain solvents.

Polystyrene used for electrical insulation, handles of tools…

Polyamide used for making ropes, belts, etc…

PVC or polyvinyl chloride for the manufacture of insulation materials, pipes, containers, etc…

Thermo-setting plastics

PROPERTIES

-

These are soluble in alcohol and certain organic solvents, when they are

in thermo-plastic stage. This property is utilized for making paints and

varnishes from these plastics.

- These are durable, strong and hard.

-

They are mainly used in engineering application of plastics.

Polyesters (thermosetting, reinforced with glass fibers)

Properties: good mechanical, electrical, and chemical properties, good

resistance to heat and chemicals

Applications: boats, luggage, swimming pools, automotive bodies, chairs

Thermo-setting plastics

General Uses

- Electronic chips

-

Fibre-reinforced composites

- Polymeric coatings

- Spectacle lenses

- Dental fillings

Homogeneous plastics

This variety of plastic contains carbon chain i.e. the plastics of this group are composed only of carbon atoms and they exhibit homogeneous structure.

Heterogeneous plastics

This variety of plastic is composed of the chain containing carbon and oxygen, the nitrogen and other elements and they exhibit heterogeneous structure.

Based on physical and mechanical properties

Soft Plastics

Semi-rigid Plastics

Elastomers

Rigid plastics

These plastics have a high modulus of elasticity and they retain their shape under exterior stresses applied at normal or moderately increased temperatures.

Semi-Rigid plastics

These plastics have a medium modulus of elasticity and the elongation under pressure completely disappears, when pressure is removed.

The plastic keys on your keyboard are hard, while the plastic around the cables of the same computer is soft.

Soft plastics

-

These plastics have a low modulus of elasticity and the elongation under pressure disappears slowly, when pressure is removed.

-

Soft plastics are available in a large range of colours, sizes and particularly shapes.

USES: Used in making children’s toys e.g.: rattles etc., fishing baits.

Elastomers

These plastics are soft and elastic materials with a low modulus of elasticity. They deform considerably under load at room temperature and return to their original shape, when the load is released. The extensions can range upto ten times their original

dimensions.

properties

-

APPEARANCE: Some plastics are completely transparent in appearance. With the addition of suitable pigments, the plastics can be made to have appearance of variety of attractive, opaque, stable and translucent colours.

-

CHEMICAL RESISTANCE: The plastics offer great resistance to moisture, chemicals and solvents. The degree of chemical resistance depends on the chemical composition of plastics. Many plastics are found to possess excellent corrosion resistance. Hence they are used to convey chemicals.

-

DIMENSIONAL STABILITY: This property of plastic favours quite satisfactory with that of other common engineering materials.

-

DUCTILITY: The plastics possess excellent electric insulating property. They are

far superior to ordinary electric insulators.

-

MELTING POINT: Most of the plastics have low melting point and the melting

point of some plastics is only about 50 C. They cannot therefore be used in

positions having high temperatures or to convey boiling water.

-

OPTICAL PROPERTY: Several types of plastics are transparent and translucent.

-

RECYCLING: The most environmentally aware people condemn the use of plastics for the amount of pollution caused by them in disposal. The plastics used for soft-drink bottles, milk and juice bottles, bread bags, syrup bottles, coffee cups, plastic utensils, etc. can be conveniently recycled into carpets, detergent bottles, drainage pipes, fencing, handrails, grocery bags, car battery cases, pencil holders, benches, picnic tables, roadside posts, etc.

-

STRENGTH: An ideal section of plastics for structural member has yet not been designed. The plastics are reasonably strong. The strength of plastics may be increased by reinforcing with various fibrous materials.

-

-

Following considerations are responsible to discourage the use of plastics as the structural material:

- The plastics are costly.

- The plastics are subject to creep under constant heavy loads.

-

The behaviour of plastics is very sensitive to the changes in

temperature.

- The stiffness of plastics is very poor

-

WEATHER RESISTANCE: Only limited varieties of plastics can be exposed to weather. The certain plastics are seriously affected by ultraviolet light in the presence of sunlight. The resistance to sunlight of such plastics can be improved by incorporating fillers and pigments which absorb or reflect the ultraviolet light at the surface. Thus the interior of plastics is protected.

-

WEIGHT: The plastics, whether thermo-plastic or thermo- setting, have low specific gravity, the average being 1.30 to 1.40. The light weight of plastics reduces the transport costs and facilitates fixing.

ADVANTAGES of plastic

- Corrosion resistance

- Very Low electrical and thermal conductivity, insulator

- Easily formed into complex shapes, can be formed, casted and joined.

- Wide choice of appearance, colors and transparencies

DISADVANTAGES of plastic

- Low strength

- Low useful temperature range (up to 314o C)

- Less dimensional stability over period of time (creep effect)

- Aging effect, hardens and become brittle over time

- Sensitive to environment, moisture and chemicals

-

Damages due to sunlight

Uses of plastic

-

There are more than 10000 different kinds of plastics available in the market and their performance abilities span those of every other known material from soft rubber to steel.

-

The typical uses of plastics in building are summarized as follows:

-

- Corrosion resistance

- Bath and sink units

- Cistern ball floats

- Corrugated and plain sheets

- Decorative laminates and mouldings

- Electrical conduits

- Electrical Insulators

-

Films for water proofing, damp

proofing and concrete curing

- Floor tiles

- Foams for thermal insulation

- Jointless flooring

- Lighting fixtures

- Overhead water tanks

- Paints and varnishes

- Pipes to carry cold water

- Roof lights

- Safety glass

- Wall tiles

-

Water resistance adhesives

Fig: GRP Pipes: Glass-Fiber Reinforced Plastic Pipes

GLASS (Introduction)

Glass is an amorphous (non- crystalline) solid which is often transparent and has widespread practical, technological, and decorative usage in things like window panes, tableware, and optoelectronics.

The most familiar, and historically the oldest, types of glass are based on the chemical compound silica (silicon dioxide), the primary constituent of sand.

Main types of glass

- Annealed glass

- Toughened glass

- Laminated glass

- Coated glass

- Mirrored glass

-

Patterned glass

Annealed (Normal) glass

- Annealed glass is the basic flat glass product that is the first result of the float process(manufacturing).

-

It is common glass that tends to break into large, jagged shards.

- It is used in some end products and often in double- glazed windows.

-

It is also the starting material used to produce more advanced products through further processing such as laminating, toughening,

coating, etc.

Toughened glass

-

Toughened glass is made from annealed glass treated with a thermal tempering process.

(A sheet of annealed glass is heated to above its “annealing point” of 600°C; its surfaces are then rapidly cooled while the inner portion of the glass remains hotter. The different cooling rates between the surface and the inside of the glass produces different physical properties, resulting in compressive stresses in the surface balanced by tensile stresses in the body of the glass.)

Toughened glass

-

-

Toughened glass is treated to be far more resistant to breakage than simple annealed glass due to counteracting stresses and to break in a more predictable way when it does break, thus providing a major safety advantage in almost all of its applications.

-

Car windshields and windows, glass portions of building facades, glass sliding doors and partitions in houses and offices, glass furniture such as table tops, and many other products typically use toughened glass.

- Annealed glass

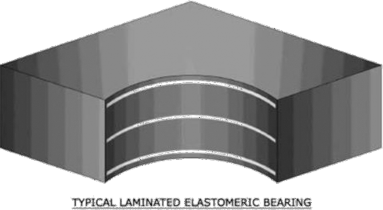

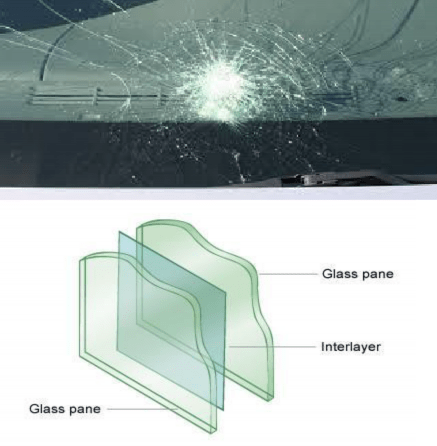

Laminated glass

-

Laminated glass is made of two or more layers of glass with one or more “interlayers” of polymeric material bonded between the glass layers.

-

Rather than shattering on impact, laminated glass is held together by the interlayer giving more safety as well as, to some degree, reducing the security risks associated with easy penetration.

Laminated glass

The interlayer also provides a way to apply several other technologies and benefits, such as colouring, sound dampening, resistance to fire, ultraviolet filtering and other technologies that can be embedded in or with the interlayer.

Coated glass

Surface coatings can be applied to glass to modify its appearance and give it many of the advanced characteristics and functions available in today’s flat glass products, such as low maintenance, special reflection/ transmission/ absorption properties, scratch resistance, corrosion resistance, etc.

Coated glass

Coatings are usually applied by controlled exposure of the glass surface to vapors, which bind to the glass forming a permanent coating.

The coating process can be applied while the glass is still in the float line with the glass still warm, producing what is known as “hard- coated” glass.

Mirrored glass

-

To produce mirrored glass, a metal coating is applied to one side of the glass. The coating is generally made of silver, aluminum and gold etc.

-

For simple mirrored glass, a fully reflective metal coating is applied and then sealed with a protective layer.

Mirrored glass

To produce “one-way” mirrors, a much thinner metal coating is used, with no additional sealing or otherwise opaque layer.

Mirrored glass is gaining a more prominent place in architecture, for important functional reasons as well as for the aesthetic effect.

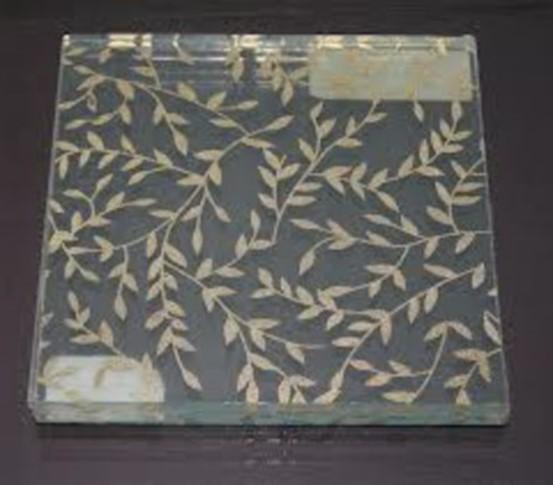

Patterned glass

Patterned glass is flat glass whose surfaces display a regular pattern.

The most common method for producing patterned glass is to pass heated glass (usually just after it exits the furnace where it is made) between rollers whose surfaces contain the negative relief of the desired pattern(s).

Patterned glass is mostly used in internal decoration and internal architecture.

Different uses

- Object and personal protection

- Fire protection

- Temporary heat and solar protection

- Use of solar energy

- Means of design

- Electromagnetic dampening.

- Supply of natural daylight

- Protection from rain, wind, and cold

- Transparency

- Means of communication

- Heat protection

-

Sound protection

Structural glass systems

Structural glass facades are most easily

categorized by the structure types that support them.

- Mullion

- Truss Systems

- Cable Truss

- Grid shells

- Cable Net

- Glass Fins

- Mullion

- Object and personal protection

- Mullion glass structure

The simplest form includes a steel or aluminum section positioned at every vertical joint in the glazing grid. These steel and aluminum sections can be designed in open or closed positions.

Mullion components often consist of built up custom structural sections capable of accommodating long spans in both vertical and horizontal positions (vertical being the most common)

Truss system

Truss systems employ a planar truss design, often in a hierarchical system that may combine other element types including tension components.

Truss designs vary widely, with an emphasis on fine detailing and draftsmanship.

Rod or cable elements may be incorporated into the truss design, and lateral tensile systems are often used to stabilize the facade structure.

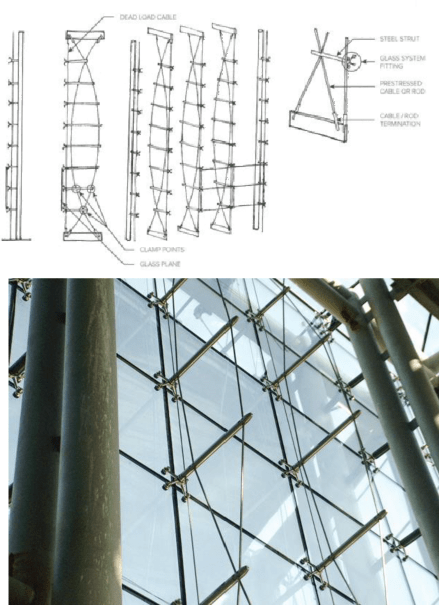

Cable truss

One type of truss system utilizes a minimalist structural form called a cable truss.

The main spinal compression element is removed, leaving the spreader struts as the sole compression elements in this truss type.

As with cable nets, these systems rely on the pre-tensioning of truss elements to provide stability, and thus benefit significantly from the early involvement of the facade design/build team.

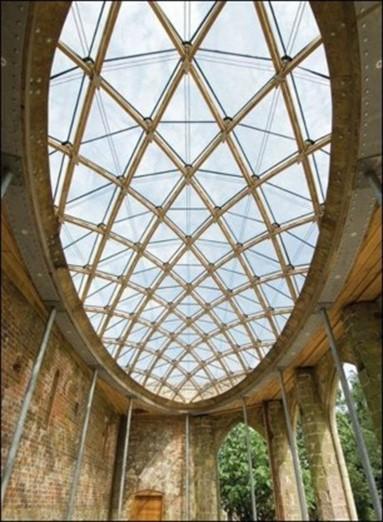

Grid shells

Grid shell structural systems are another means to minimize the visual mass of structure.

Configurations can be vaulted, domed and double-curved.

Systems can be welded, bolt-up, or some combination of each.

Grid shell structures with integrated cable bracing can produce a highly efficient structure with a refined aesthetic.

Grid shells can be used in vertical and overhead applications, as well as to form complete building enclosures.

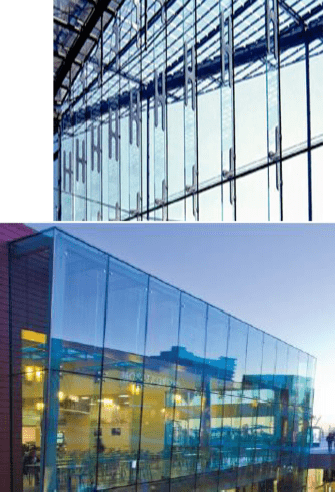

Cable net

-

This new generation of glass walls allows for the design of highly transparent facades and blast resistant applications.

-

The glass is supported by a net geometry of pre-tensioned cables.

-

A clamping component locks the cables together at their vertices and fixes the glass to the net.

Glass fins

This technology was popularized by the Willis Faber & Dumas Building, Ipswich, England circa 1972.

In this glass plates are suspended and laterally stiffened by the use of glass fins set perpendicular to the plates at the vertical joints between them.

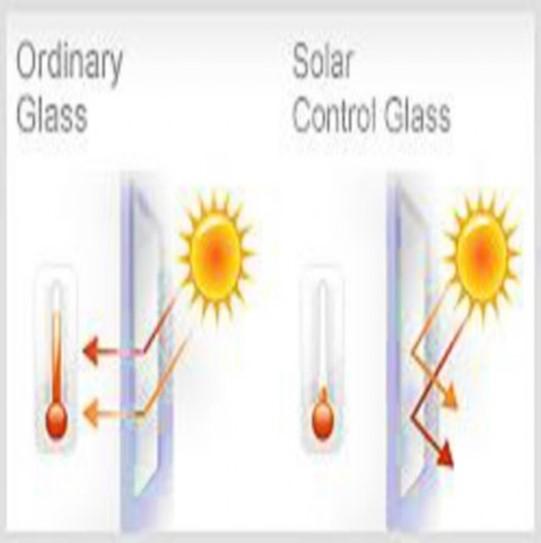

Glass for green buildings

Reflective glasses come with reflective coating that filters heat and let optimum light into the building.

Reduce the heat gain inside the building, and thus reduces electricity and cooling costs

Allow optimum light (natural daylighting) inside the building, and thus reduces the cost for artificial lighting