Light Gauge Steel Construction Concepts

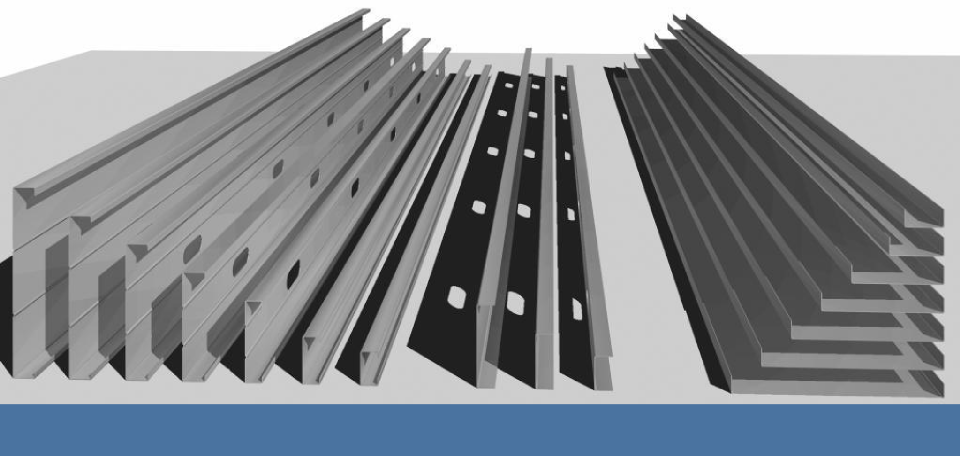

Light Gauge Steel Framing Members

Steel components are cold-rolled from steel sheet.

Light Gauge Steel Construction Concepts

C-Studs and Joists

Wall studs, floor joists, roof rafters, etc.

Depth 1-5/8 to 12 in. Width 1-1/4 to 2-1/2 in. Metal thickness 0.018 to

0.097 in. (18 to 97

mils)

Fundamentals of Building

Light Gauge Steel Construction Concepts

Example designation: 600S162-54

600: 6.00 inches deep S: c-shaped Stud or joist

162: 1.625 (1-5/8)

inches wide

54: 54 mils metal thickness

Fundamentals

Light Gauge Steel Construction Concepts

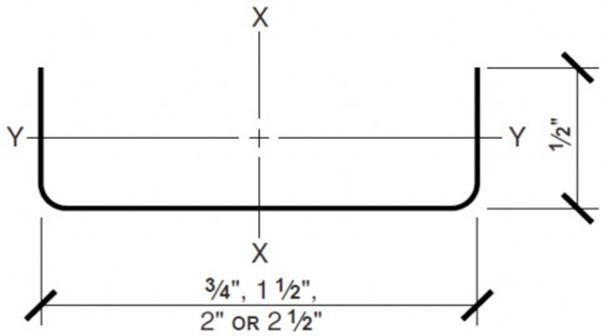

Tracks

Top and bottom of wall framing; ends of floor framing

Analogous to wall plates and rim joists in light wood frame construction

Fundamentals

Light Gauge Steel Construction Concepts

Depth to match studs or joists

Width 1-1/4 to 2 in. Example 600T125-33:6.00 inches deep track,

1.25 in. wide, 33 mils metal thickness

Fundamentals of Building Construction, Materials & Methods, 6th Edition

Copyright ©

Light Gauge Steel Construction Concepts

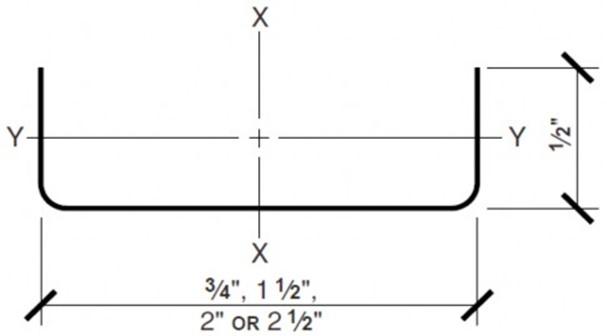

Channels

Bridgng, blocking, and other reinforcing and bracing

Also called cold- formed channels Standard sizes

Depth ¾ to 2-1/2 in. Width ½ in.

Light Gauge Steel Construction Concepts

Example 075U50-54:

0.75 in. deep, U- channel, 0.50 inches wide, 54 mils metalthickness

Fundamentals of Building Construction, Materials & Methods, 6th Edition

Copyright © 2013 J.

Light Gauge Steel Construction Concepts

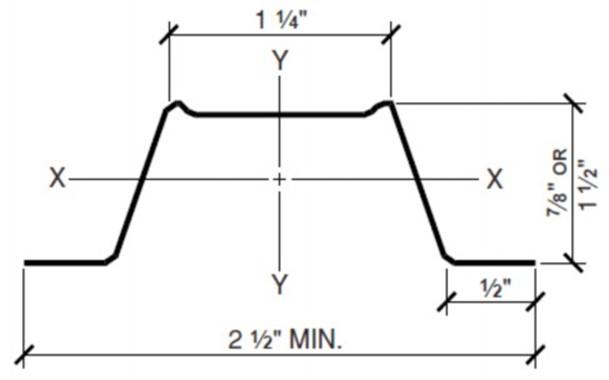

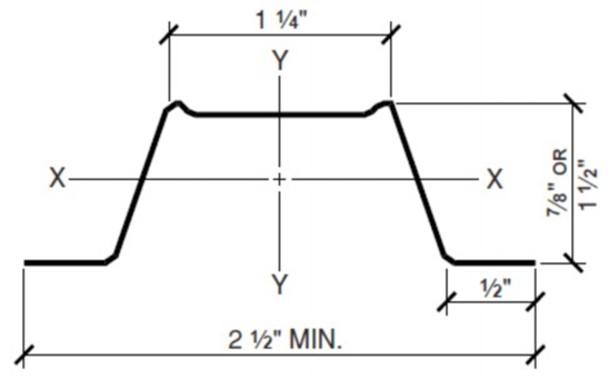

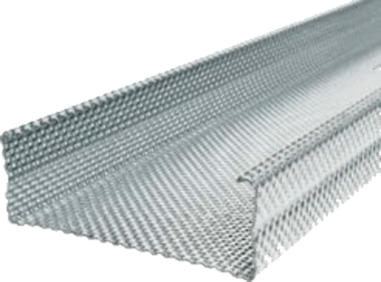

Furring

Used for bridging, backing, furring Also called hat

channels

Standard sizes

Depth 7/8 or 1-1/2 in. Width 1¼ in. at raised surface, 2½ in. at

base

Fundamentals of Building Construction, Materials & Methods, 6th Edition

Light Gauge Steel Construction Concepts

Example

087F125-30: 0.875

in. deep furring channel, 1.25 inches wide at raised surface, 30 mils metal thickness

Fundamentals of Building Construction, Materials & Methods, 6th Edition

Copyright © 2013 J.

Light Gauge Steel Construction Concepts

L-Headers

Used for simplified header construction in bearing wall openings.

Break-formed angles (sheet metal bent in fabricator’s shop to the specified size)

Fundamentals of Building Construction, Materials & Methods, 6th

Light Gauge Steel Construction Concepts

Section View

Long leg 6 to 10 in. Short leg 1½ in.

Example

2-800L150-43:

2 (doubled) angles,

-

in. long leg L- Header, 1.5 in. short leg, 43 mils metal thickness

Light Gauge Steel Construction Concepts

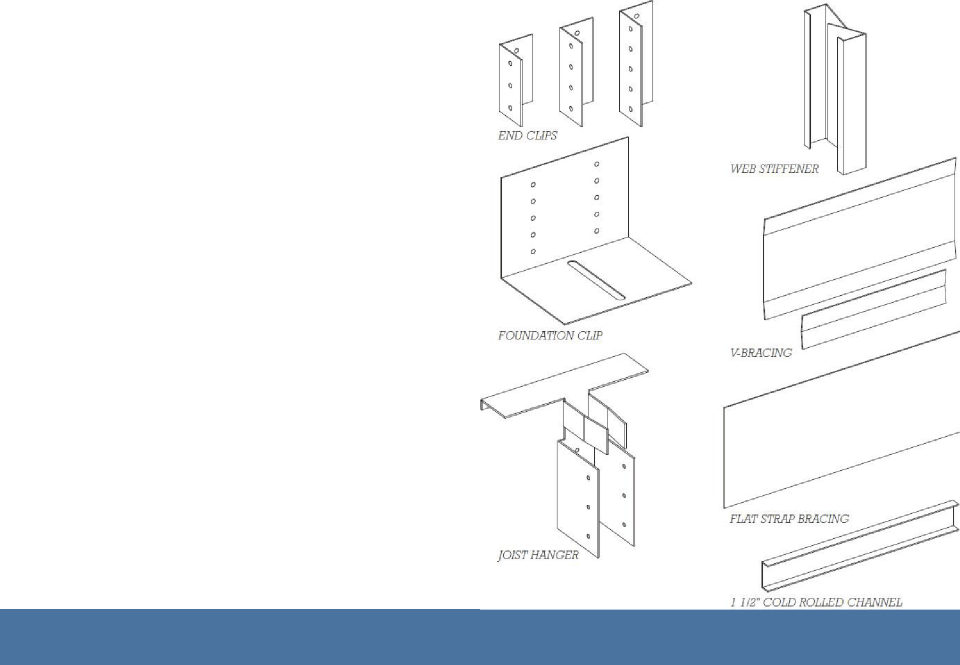

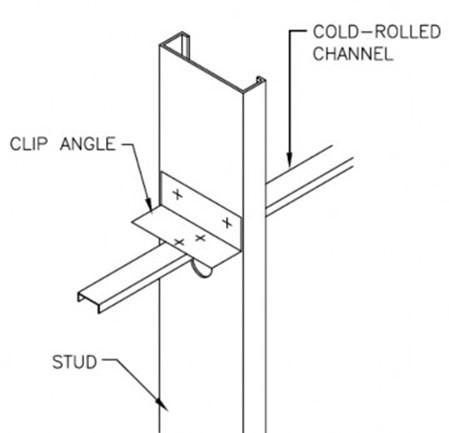

Framing Accessories

Various sheet metal clips, stiffeners, bracing, and hangers are used to make connections and reinforce framing.

Light Gauge Steel Construction Concepts

Special Products

Proprietary shapes or products that are stiffer or stronger, compared to conventional members of the same metal thickness.

right: Heavily folded or specially shaped member members

Light Gauge Steel Construction Concepts

Heavily dimpling metal results in a stiffer framing member.

Fundamentals of Building Construction, Materials & Methods, 6th Edition

Copyright © 2013 J. Iano. All rights reserved.

Light Gauge Steel Construction Concepts

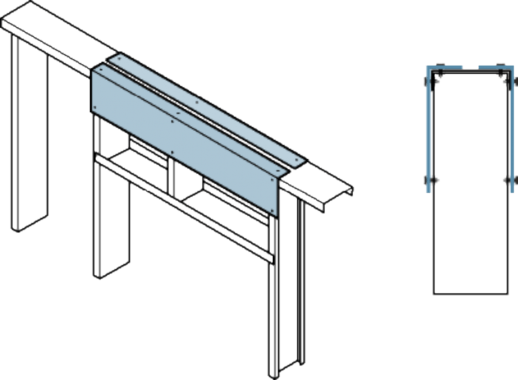

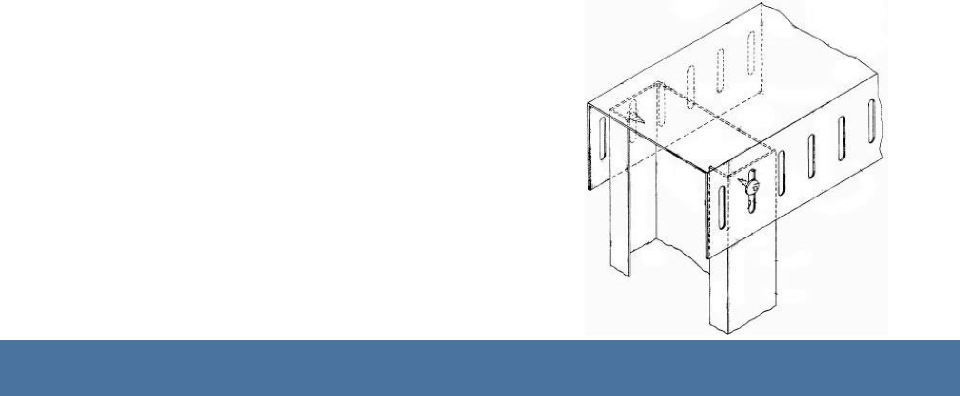

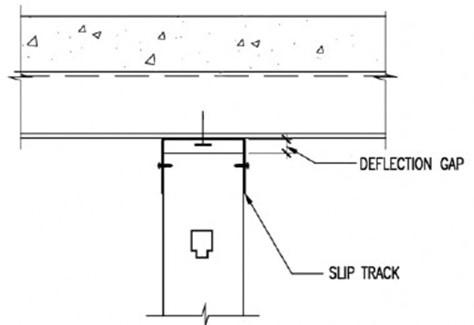

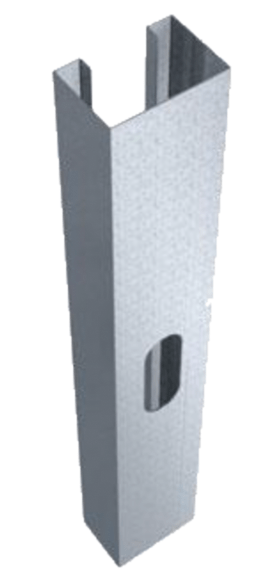

Slip Track

Top track with extra deep legs and slotted holes

Allows fastening of nonloadbearing studs to track while permitting deflection in the track

Light Gauge Steel Construction Concepts

Studs are cut short to maintain deflection gap.

Deflection in the slab above does not impart unintended loads into the wall framing.

Fundamentals of Building Construction, Materials &

Light Gauge Steel Construction Concepts

Jamb Stud

Single, deeper framing member designed to replace two conventional studs at either side of a framed rough opening

Fundamentals of Building Construction, Materials &

Light Gauge Steel Construction Concepts

Sheet Metal Thickness

Minimum thickness of steel sheet Gauge

Loadbearing

framing

Nonloadbearing

framing

12

0.097 in. (2.46 mm) 14

0.068 in. (1.73 mm) 16

0.054 in. (1.37 mm) 0.054 in. (1.37 mm) 18

0.043 in. (1.09 mm) 0.043 in. (1.09 mm) 20

0.033 in. (0.84 mm) 0.030 in. (0.75 mm) 22

0.027 in. (0.69 mm) 25

0.018 in. (0.45 mm) Thicker members are stronger and stiffer, but also heavier and more expensive.

Fundamentals of Building Construction, Materials & Methods

Light Gauge Steel Construction Concepts

Minimum thickness of steel sheet

GaugeLoadbearing

framingNonloadbearing

framing

12

0.097 in. (2.46 mm)

14

0.068 in. (1.73 mm)

16

0.054 in. (1.37 mm)

0.054 in. (1.37 mm)

18

0.043 in. (1.09 mm)

0.043 in. (1.09 mm)

20

0.033 in. (0.84 mm)

0.030 in. (0.75 mm)

22

0.027 in. (0.69 mm)

25

0.018 in. (0.45 mm)Traditionally expressed as gauge (or gage), with lower numbers corresponding to thicker metal.

Fundamentals of Building Construction, Materials & Methods, 6th Edition

Light Gauge Steel Construction ConceptsMinimum thickness of steel sheet

GaugeLoadbearing

framingNonloadbearing

framing

12

0.097 in. (2.46 mm)

14

0.068 in. (1.73 mm)

16

0.054 in. (1.37 mm)

0.054 in. (1.37 mm)

18

0.043 in. (1.09 mm)

0.043 in. (1.09 mm)

20

0.033 in. (0.84 mm)

0.030 in. (0.75 mm)

22

0.027 in. (0.69 mm)

25

0.018 in. (0.45 mm)Gauge numbers still used in common parlance but, contemporary standards specify metal thickness in decimal inches.

Fundamentals of Building Construction, Materials & Methods, 6th EditionCutting Light Gauge Sheet Metal

Tin snips (aviator’s snips): quiet, clean, slower than power methods

Power shears Power saw with abrasive or carbide-

toothed blade

Torch cutting

Light Gauge Steel Construction ConceptsFastening

Self-drilling, self-tapping screws are most common. Crimping tools mutually

deform parts to be joined.

Nail-like pins are power- driven.

Light Gauge Steel Construction ConceptsWelded joints can achieve higher strengths but are more labor intensive to make than mechanically fastened joints.

Welding is best suited to thicker sheets that are less susceptible to melt-through (burn through) than thinner sheets.

Fundamentals of Building Construction, Materials & Methods, 6th Edition

Copyright © 2013 J. Iano. All rights reserved.

Light Gauge Steel Construction ConceptsTop: Plug welds Middle: Slot welds

Bottom: Flare vee weldFundamentals of Building Construction, Materials & Methods, 6th EditionCopyright © 2013 J. Iano. All rights reserved.

12 LIGHT GAUGE STEEL FRAME CONSTRUCTIONLIGHT GAUGE STEEL FRAMING

Fundamentals of Building Construction, Materials & Methods, 6th Edition

Copyright © 2013 J. Iano. All rights reserved.

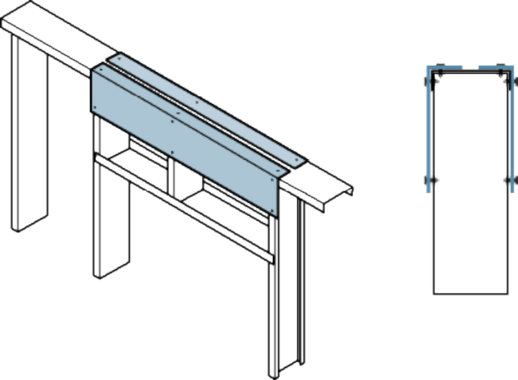

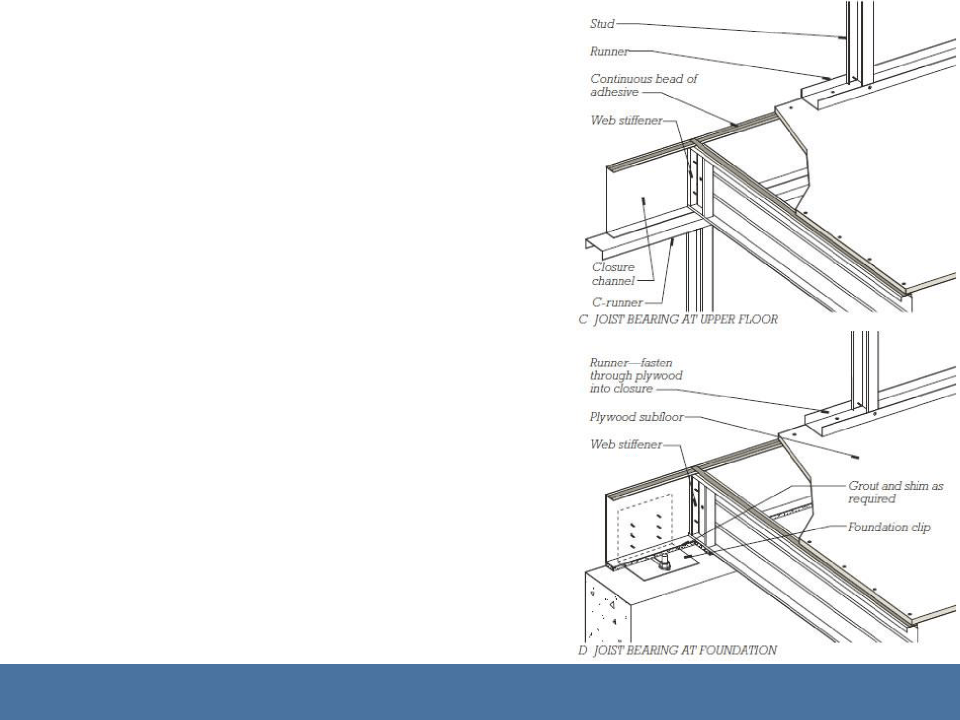

Light Gauge Steel FramingFraming

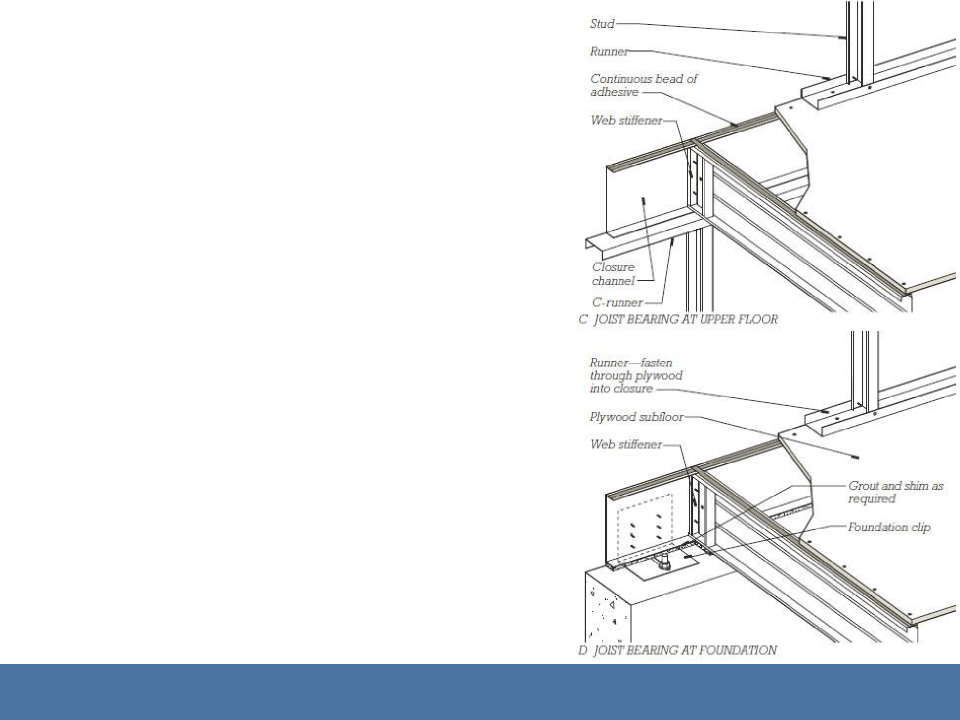

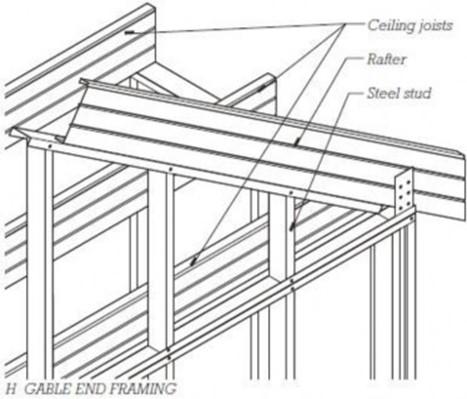

Framing methods parallel wood light frame platform construction.

Steel joists spaced from 12 to 24 in. o.c. are framed into tracks or channels.

Copyright © 2013 J. Iano. All rights reserved.

Light Gauge Steel FramingWeb stiffeners or reinforcing are inserted where concentrated might buckle the thin joist webs.

Construction panels are fastened with mastic adhesive and self- drilling screws.

Light Gauge Steel Framing

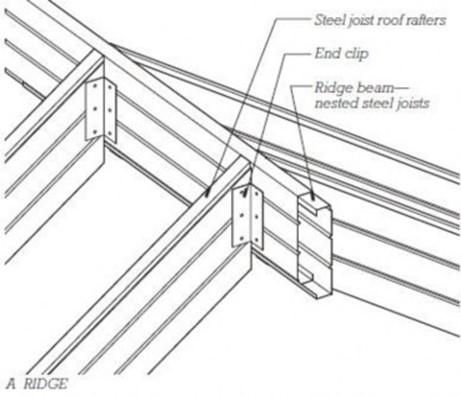

Heavier beam equivalents, such as the ridge beam in the top illustration, can be constructed by nesting standard joists.

Simple angles or end clips facilitate joining of perpendicular members.

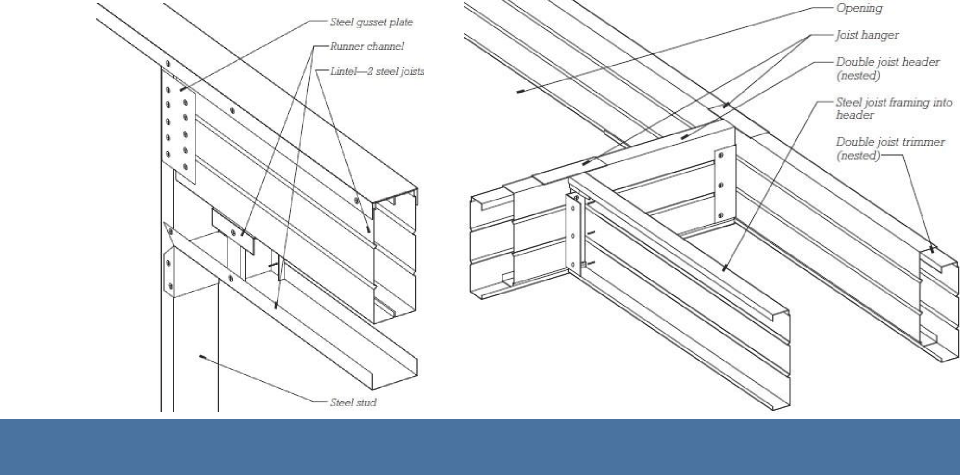

Light Gauge Steel FramingJoist hangers, gusset plates, and folded track ends are other connection methods.

Copyright © 2013 J. Iano. All rights reserved.

Light Gauge Steel FramingWindow header connection to supporting studs

Light Gauge Steel FramingBracing

The slender steel members require bracing at regularly spaced intervals to reduce the tendency to buckle.

Light Gauge Steel FramingSpecifying Light Gauge Steel Framing

Two distinct trades: Division 5 Metals,

Section 05 40 00—Cold-

Formed Metal Framing For structural, loadbearing framing

and exterior wall

framing (subject to wind loads)

Fundamentals of Building Construction, Materials &

Light Gauge Steel Framing

Division 9 Finishes

Section 09 22 16— Non-Structural Metal Framing

For interior nonloadbearing framing

Light Gauge Steel Framing

Compared to Light Wood Framing

Advantages

Versatile, flexible, simple to construct

Noncombustible and immune to insect attack- Dimensionally stable, with consistent material properties

-

Lighter weight

Fundamentals of Building Construction, Materials & Methods, 6th Edition

Copyright © 2013 J. Iano. All rights reserved.

Light Gauge Steel Framing

Compared to Light Wood Framing

Disadvantages

- Members require more frequent bracing

- Readily conducts heat and requires extra attention to eliminating thermal bridging effects

- Susceptible to corrosion

- Dimensionally stable, with consistent material properties

Fundamentals of Building Construction, Materials & Methods, 6th Edition