FORMWORK

What is Formwork?

-

Formwork is a mould including all supporting structures, used to shape and support the concrete until it attains sufficient strength to carry its own weight.

-

It should be capable of carrying all imposed dead and live loads apart from its own weight.

Formwork is commonly made of

- Steel

- Timber

- Steel

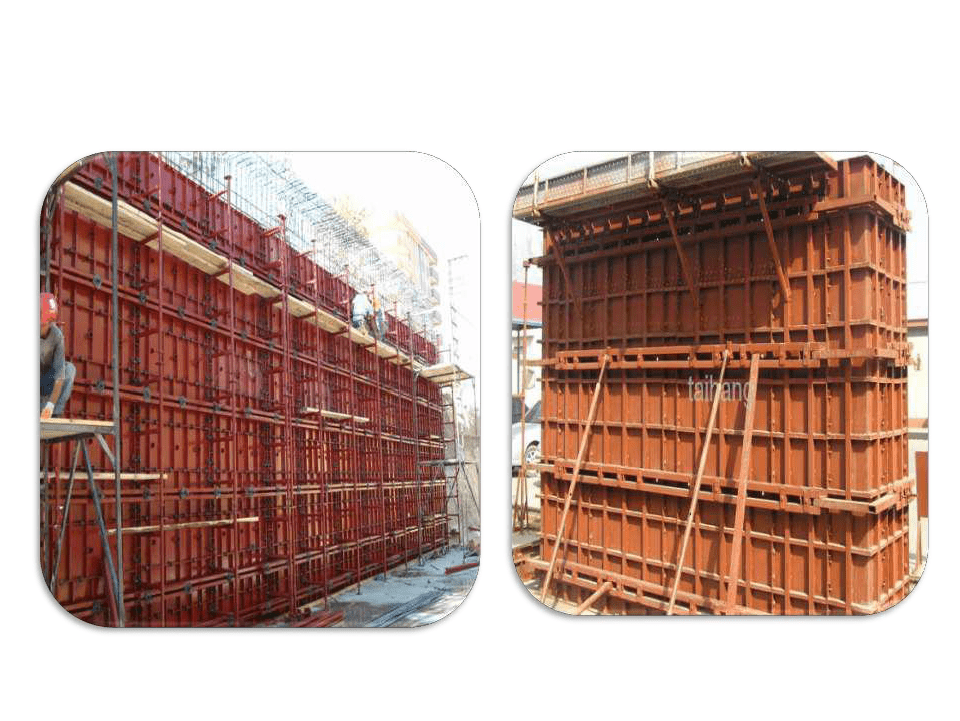

TIMBER FORMWORK

STEEL FORMWORK

- Formwork has been in use since the beginning of concrete construction.

- New materials such as steel, plastics and fibreglass are used in formwork.

- Greater attention is being given to the design, fabrication, erection and dismantling of formwork

- Formwork is designed according to The ACI document SP-4.

Qualities of Formwork

- It should be water tight.

- It should be strong.

- It can be reusable.

- Its contact surface should be uniform.

- It should be according to the size of member.

-

In order to successfully carry out its function, formwork must achieve a balance of following requirements:

- Containment

- Strength

- Resistance To Leakage

- Accuracy

- Ease Of Handling

- Finish And Reuse Potential

- Access For Concrete

- Economy

- Containment

-

Containment: formwork must be capable of shaping and supporting the fluid concrete until it cures.

-

Strength: formwork must be capable of safely withstanding without distortion or danger the dead weight of the fluid concrete is placed on it, labour weight, equipment weight and any environmental loadings.

-

Ease of Handling: form panels and units should be designed so that their maximum size does not exceed that which can be easily handled by hand or mechanical means.

-

In addition all formwork must also be designed and constructed to include facilities for adjustments, levelling, easing and striking without damage to the form work or concrete.

-

-

Economy: all the formwork is very expensive. On average about 35% of the total cost of any finished concrete unit or element can be attributed to its formwork; of this just over 40% can be taken for material for formwork and 60% for labour.

-

The formwork designer must therefore not only consider the maximum number of times that any form can be reused, but also produce a design that will minimize the time taken for erection and striking.

-

-

Major objectives considered in formwork:

Quality

Safety

Economy

-

Quality:

Forms must be designed and built with sufficient stiffness and accuracy so that the size, shape, position, and finish of the cast concrete are maintained.

-

Safety:

Forms must be built sufficient strength and factor of safety the capable of all supporting loads.

-

Economy:

Forms must be built efficiently, minimizing time and cost.

so that they have

Requirements of formwork:

- Material should be cheap and re usable,

- It should be practically water proof, so that it should not absorb water from concrete,

- Swelling and shrinkage should be minimum,

- Strong enough to with stand all external loads,

- Deflection should be minimum,

- Surface should be smooth

- Light in weight, so that easy to transfer,

- Joints should be stiff, so that lateral deformation and leak

- Material should be cheap and re usable,

is minimum .

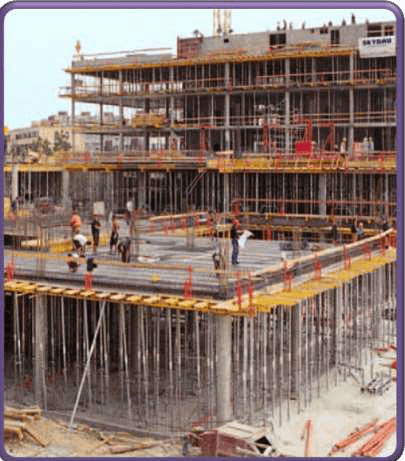

Three stages in the process :

-

Assembly and erection .

-

Concrete placement.

-

Stripping and dismantling.

-

Formwork detail for different

structural members

In concrete construction formwork is commonly provided for the following structural members.

- Wall

- Column

- Slabs & Beams

- Stairs

- Chimneys

-

Water tanks

-

Formwork for Wall

-

It consists of

- Timber sheeting

- Vertical posts

- Horizontal members

-

Rackers

- Timber sheeting

- After completing one side of formwork reinforcement is provided at the place then the second side formwork is provided.

-

-

- Wall

-

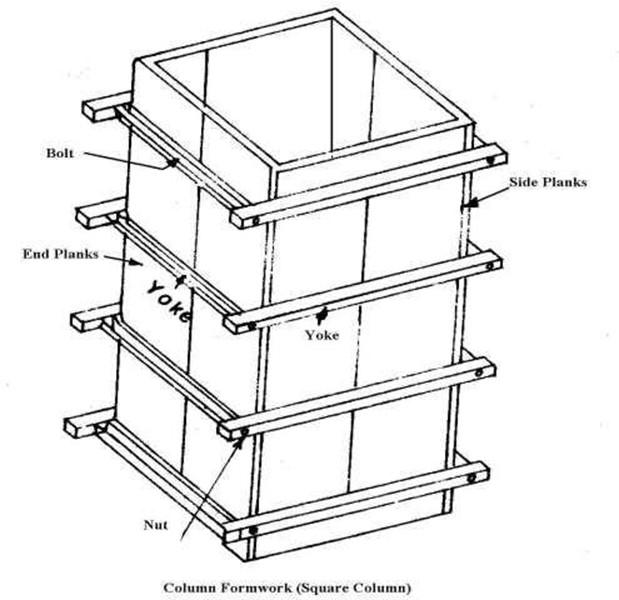

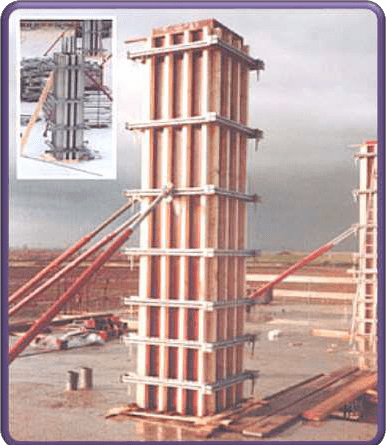

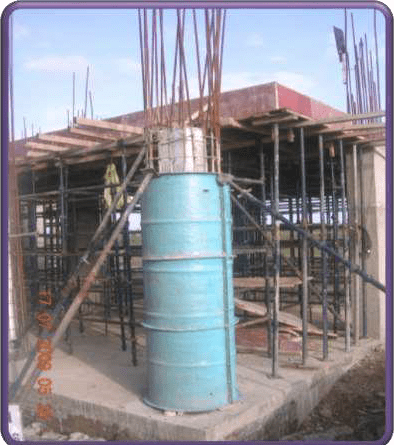

Formwork for Column

-

It consists of the following

- Side & End Planks

- Yoke

- Nut & Bolts

- Side & End Planks

-

Two end & two side planks are joined by the yokes and bolts.

- Formwork for columns

-

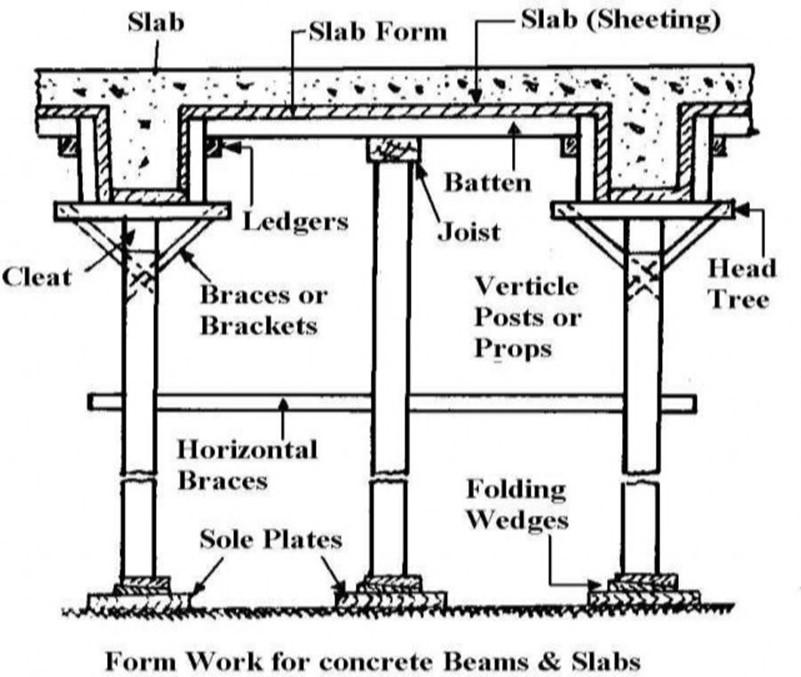

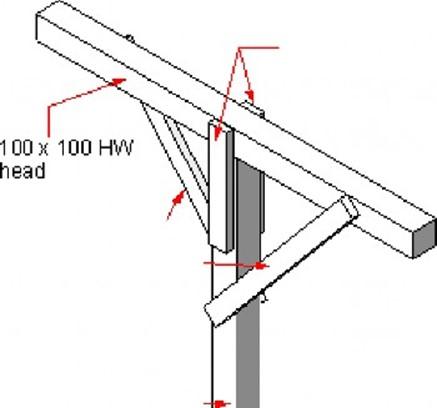

Formwork for Slabs & beams•:

It consists of

- Sole plates

- Wedges

- Props

- Head tree

- Planks

- Batten

-

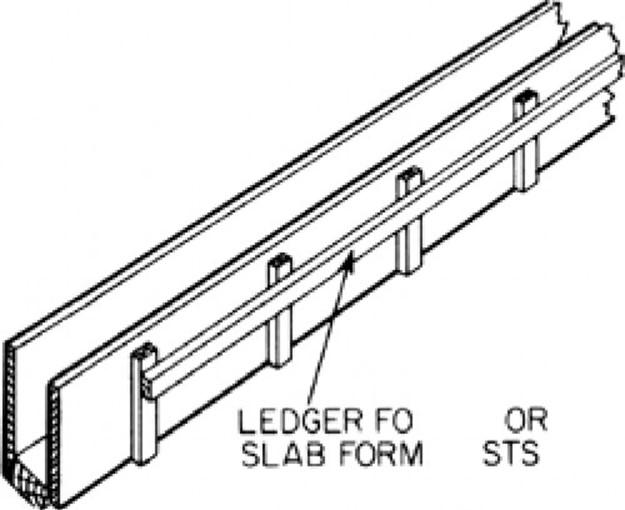

Ledgers

- Beam formwork rests on head tree

-

Slab form work rests on

battens and joists

- If prop height are more than 8′ provide horizontal braces.

- Beam formwork rests on head tree

- Sole plates

-

-

FORMWORK FOR SLAB:

-

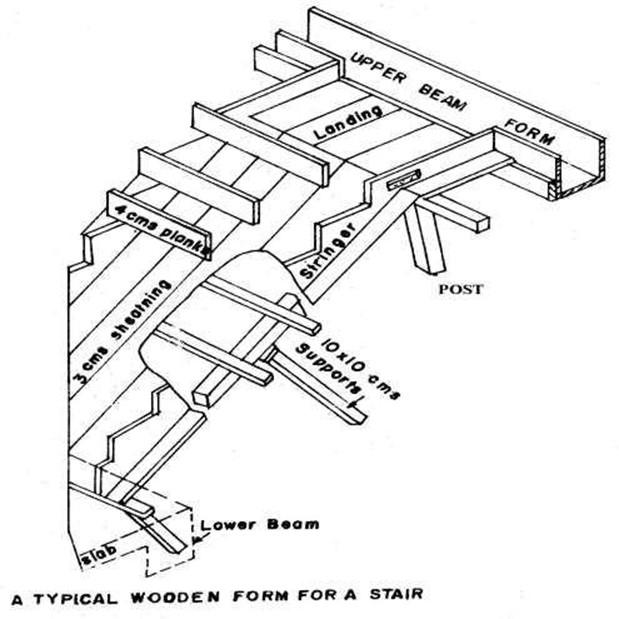

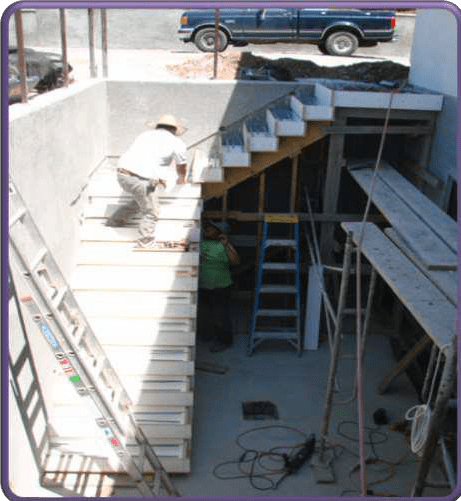

FORMWORK FOR STAIRS:

-

It consists of

- Vertical & inclined posts

-

Inclined members

— Wooden Planks or sheeting

- Stringer

- Riser Planks

- Vertical & inclined posts

- FORMWORK FOR STAIRS:

-

-

-

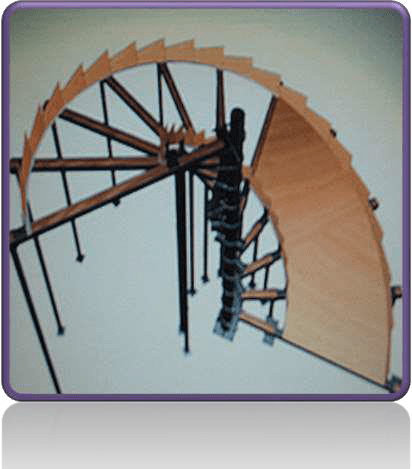

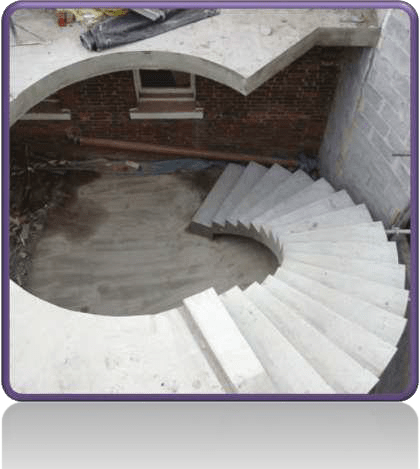

FORMWORK FOR SPIRAL STAIRS :

-

FORMWORK FOR CHIMNEYS:

For tall chimneys two types of forms techniques are in generally use in our country

- Jump form

- Slip form

- Jump form

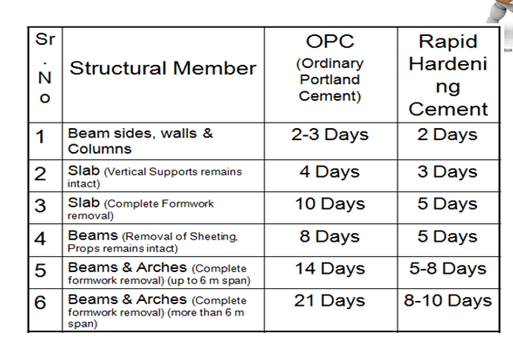

- Removal of formwork:

- Time of formwork removal depends on the following factors

-

Type of Cement

- Rapid hardening cements require lesser time as compared to OPC (Ordinary Portland Cement)

-

Ratio of concrete mix

- Rich ratio concrete gain strength earlier as compared to weak ratio concrete.

- Rich ratio concrete gain strength earlier as compared to weak ratio concrete.

-

Weather condition

- Hydration process accelerates in hot weather conditions as compared to cold and humid weather conditions.

- Hydration process accelerates in hot weather conditions as compared to cold and humid weather conditions.

- Rapid hardening cements require lesser time as compared to OPC (Ordinary Portland Cement)

Time of Removal of formwork:

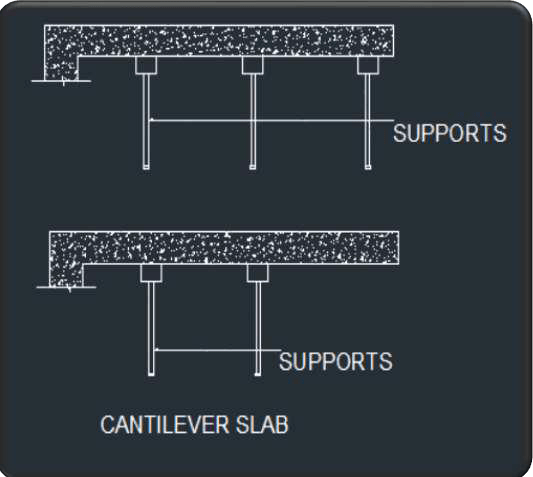

Cantilever slab

-

First free end’s support should be removed.

-

And then from right to left it

should be proceed.

-

If we are removing from the mid span then it will act as a prop cantilever.

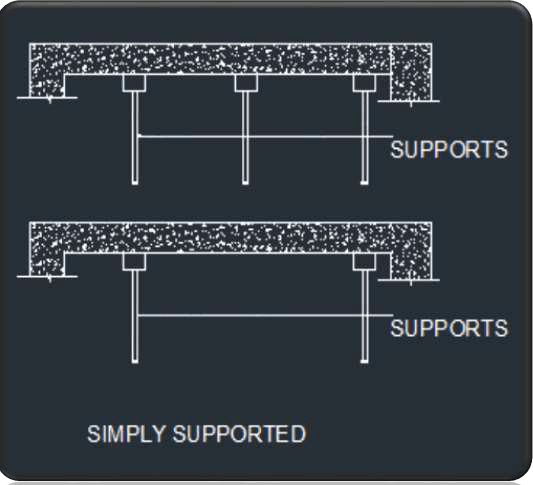

Simply supported slab

-

In simply supported we

have to remove the support from the mid span to the ends.

- To meet the design behavior.

-

-

Maintenance of formwork:

- Due to continuous use wooden planks & steel plates surfaces become uneven and require maintenance.

- For wooden formwork use cardboard or plastic fiber board. Bolt hole places must also be repaired.

-

For steel formwork plates must be leveled by mallet and loose corners must be welded.

-

Cost of formwork

-

For normal works cost of formwork is about 30%-40%

of the concrete cost.

-

For special works cost of formwork is about 50%-60%

of the concrete cost.

-

Formwork cost is controlled by the following factors

- Formwork Material cost

- Formwork erecting cost

- Formwork removal cost

- Formwork jointing cost (Nails and Cables)

- Labor charges.

- Formwork Material cost

-

-

- Due to continuous use wooden planks & steel plates surfaces become uneven and require maintenance.

-

Advantages of steel form work:

- It can be used for a no. of times.

- It is non absorbent.

- Smooth finish surface obtained.

- No shrinkage of formwork occurs.

- Easy to use.

- Its volume is less

- Its strength is more.

- LOADS ON FORMWORK:

- It can be used for a no. of times.

-

Dead load

- Self weight of formwork

- Pressure and loads from fresh concrete

- Reinforcement

- Self weight of formwork

-

Imposed load

-

Construction workers

- Stacking of materials

-

- Horizontal loads

-

Environmental loads

- Accidental loads

- Wind loads

- Accidental loads

Thank you

THANK YOU