Portland Cement Concrete

BUILDING MATERIALS

Portland Cement Concrete

-

Portland cement concrete is a “concrete”, or artificial rock composed of aggregates, water, and a cementing agent.

-

Portland cement=(Limestone +Silica

+Alumina +Iron) are mixed

- Burned

- Ground (grind)

- Main component is Lime (60%-75%)

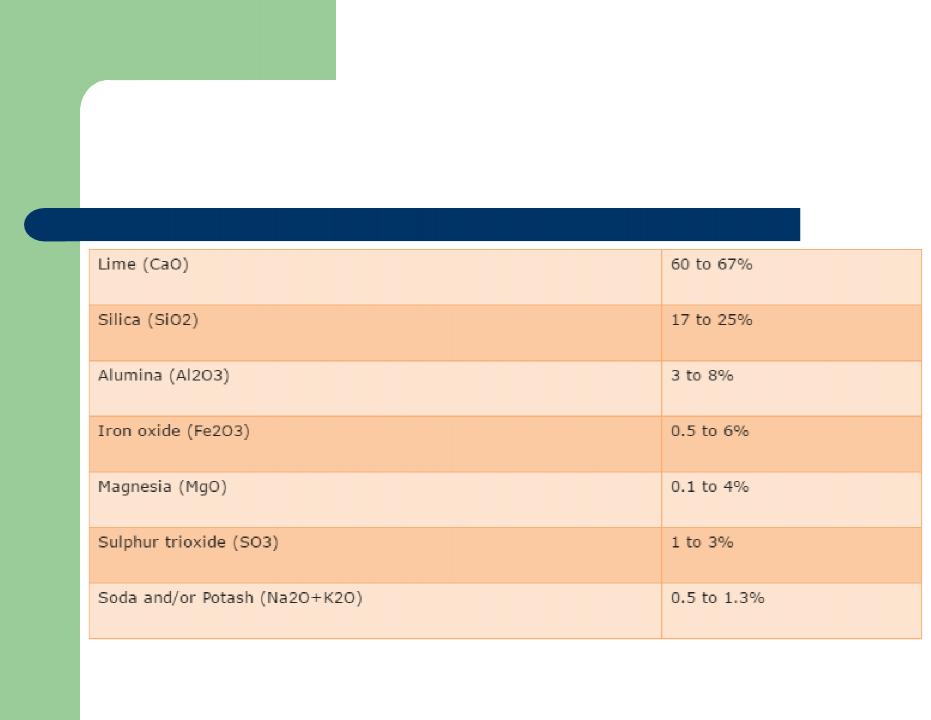

The major constituents of Portland cement are as follows

The above constituents chemical reactions during burning and fusion, combine to form the following compounds are

The cement compounds produced are:

- C3S

- C2S

- C3A

-

C4AF

Percentage of each depends on required properties:

- Rate of hydration

- Amount of heat given off

- Chemical attack

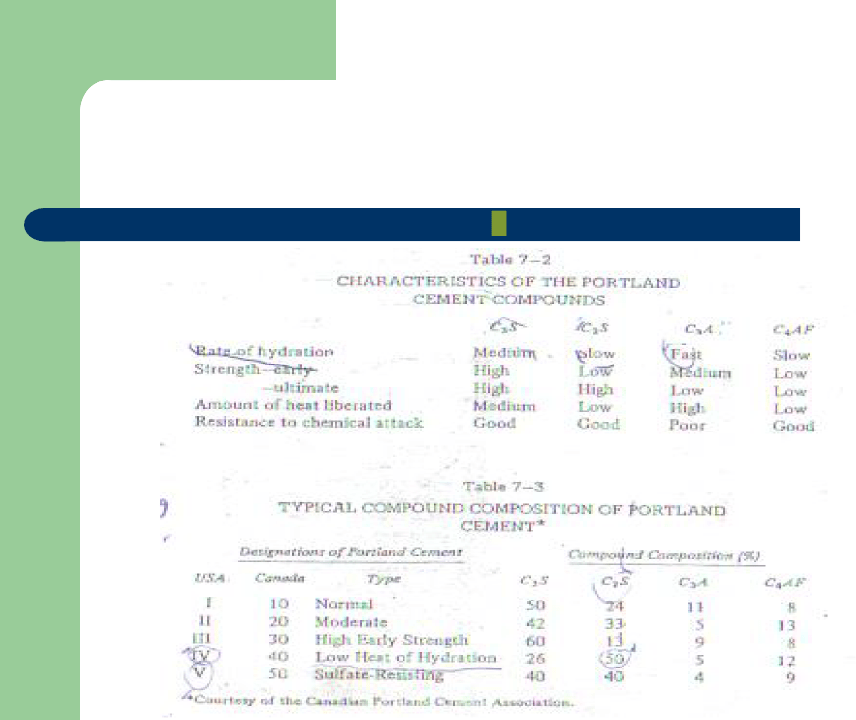

Characteristics of the Portland cement compounds

- C3S: hardness rapidly, responsible for the initial set & early strength.

- C2S: hydrates slowly, low heat of hydration

- C3S + C2S: responsible for the strength of concrete

- C3A: reacts very quickly

- C4AF: reduce temperature required during burning in the kiln

-

C3A&C3S: rate of release of heat is greatest

Types of Portland cement

- I : Normal

- II: Moderate, moderate resistance to sulfate

- III: High early strength, in case where early high strength is required.

- IV: Low heat of hydration, (slow reacting)

-

V: Sulfate resisting

Types of Portland cement

Properties of Portland cement

- Fineness: govern rate of hydration

- Setting

- Compressive strength

- Tensile strength=10% of compressive strength

Properties of Portland cement concrete

- Fineness: govern rate of hydration

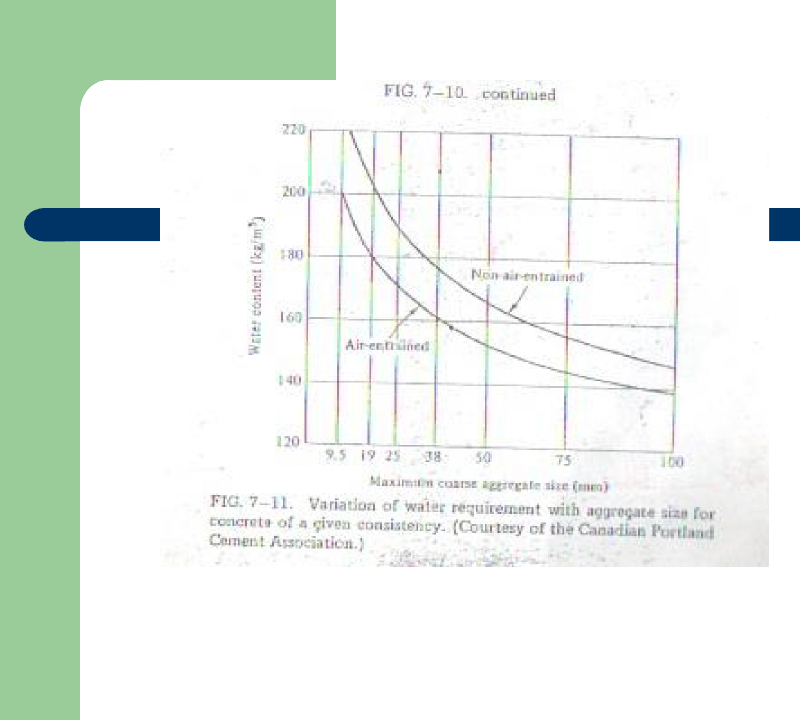

- W/C ratio (w/c=0.4-0.7)

-

Water is required in the mixture for two purposes:

- Hydration

- Workability

Properties of Portland cement concrete

- Compressive strength

- Hydration

-

The strength at 3,7,and 14 days is about 40%,60%, and 75% respectively of 28 day strength.

- tensile strength= 10% compressive strength.

Materials

- tensile strength= 10% compressive strength.

- Concrete composed of:

- cement

- water

- fine aggregate

- coarse aggregate

- admixtures.

Materials

Water

- Drinkable

- No definite taste or odor

- Municipal Water Supply

- Ice can be used in hot weather but during mixing it

should fully melted.

ASTM C1602, Standard Specification for Mixing Water Used in the Production of Hydraulic Cement Concrete

Normal-Weight Aggregate

ASTM C 33

Most common aggregates

Sand Gravel

Crushed stone

Produce normal-weight concrete 2200 to 2400 kg/m3

According to Size:

Fine aggregate: d ≤ 5 mm

Coarse aggregate: d > 5 mm

Fine Aggregate

-

Sand and/or crushed stone dust

-

< 5 mm

-

F.A. content usually 35% to 45% by mass or volume of total aggregate

Coarse Aggregate

- Gravel and crushed stone

- > 5 mm

-

typically between

-

and 37.5 mm

Aggregate Characteristics and Tests

-

- Gravel and crushed stone

| Characteristic |

Test |

| Abrasion resistance | ASTM C 131 (AASHTO T 96), ASTM C 535, ASTM C 779 |

| Freeze-thaw resistance | ASTM C 666 (AASHTO T 161), ASTM C 682, AASHTO T 103 |

| Sulfate resistance | ASTM C 88 (AASHTO T 104) |

| Particle shape and surface texture |

ASTM C 295, ASTM D 3398 |

| Grading | ASTM C 117 (AASHTO T 11), ASTM C 136 (AASHTO T 27) |

| Fine aggregate degradation | ASTM C 1137 |

| Void content | ASTM C 1252 (AASHTO T 304) |

| Bulk density | ASTM C 29 (AASHTO T 19) |

Aggregate Characteristics and Tests

| Characteristic |

Test |

| Relative density | ASTM C 127 (AASHTO T 85)—fine aggregate ASTM C 128 (AASHTO T 84)—coarse aggregate |

| Absorption and surface moisture |

ASTM C 70, ASTM C 127 (AASHTO T 85), ASTM C 128 (AASHTO T 84), ASTM C 566 (AASHTO T 255) |

| Strength | ASTM C 39 (AASHTO T 22), ASTM C 78 (AASHTO T 97) |

| Def. of constituents | ASTM C 125, ASTM C 294 |

| Aggregate constituents | ASTM C 40 (AASHTO T 21), ASTM C 87 (AASHTO T 71), ASTM C 117 (AASHTO T 11), ASTM C 123 (AASHTO T 113), ASTM C 142 (AASHTO T 112), ASTM C 295 |

| Alkali Resistance | ASTM C 227, ASTM C 289, ASTM C 295, ASTM C 342, ASTM C 586, ASTM C 1260 (AASHTO T 303), ASTM C 1293 |

Aggregates

Minimum amount of fine aggregates passing 300 micro m and 150 micro m 10% & 20% respectively is required to insure smoothness

Aggregates

-

Cement paste must cover each particle

-

The larger size of aggregate, the more economical the concrete is. This is because there will be less voids space between aggregates to be filled with expensive paste concrete.

Aggregates

-

The larger of size aggregates the less need of water, so the more strength of concrete, or the less amount of needed cement.

Aggregates

-

Fineness Modulus:

Sum. of accumulative %retained or 9.5mm, 4.75mm, 2.36mm, 1.18mm, 6.00micro m, 300micro m and 150 micro m sieves divided by 100.

- To ensure that an aggregate does not fall beyond to the coarse or fine side of the limits for sieves sizes.

-

Useful in choosing proportions in trial mixes.

-

According to Unit Weight:

Heavy weight agg.: Hematite, Magnetite Specific Gravity, Gs > 2.8

Normal weight agg.:Gravel, sand, crushed stone 2.8 < Gs < 2.4

Light weight agg.:Expanded perlite, burned clay Gs < 2.4

Uses Of Aggregates

Concrete

Roads

Railway

Additive and Admixtures

Any chemical / substance added to cement during its manufacture to improve the quality of concrete or to obtain any desired effect on concrete is called Additive.

Any substance added to concrete during its mixing to improve its quality in a desired way is called Admixture.

Reference: Additive and Admixtures from Concrete.

Structures byZ.A Siddiqi

Admixtures

Purposes:

- To improve the concrete properties

- To aid in construction procedures

- To provide economy

The admixtures may be of the following general types:

z Accelerators.

z Set-retarders.

z Plasticizers or water-reducers.

z Super-plasticizers.

z Cementing admixtures.

z Gas forming or air-entraining agents.

z Bonding admixtures.

z Sealing agents.

-

Accelerators

z The admixtures that accelerate the hardening of concrete in order to get development of

early strength are called accelerators.

z Quick-setting admixtures are also available which cause flash set, such as washing soda or sodium carbonate.

-

Set-Retarders

z These admixtures cause delay in setting of concrete.

z These are useful for mass concreting, concreting in hot weather, improving the construction joints and for obtaining special architectural surface finishes.

-

Plasticizers Or Water- Reducers

z These admixtures reduce the amount of water required for a desired workability.

z This reduction in the water-cement ratio increases the strength of concrete.

-

Super-Plasticizers

z These are used to make flowing concrete that can be compacted into difficult places without any vibrations.

These are helpful in maintaining very low water / cement ratios and to achieve very high strength

concrete.

-

Cementing Admixtures

Pozzolans are the materials that provide cementitious properties and may replace cement up to about 40 per cent.

Volcanic ash, pumicite, opaline shales, calcined diatomaceous earth, burnt clay, fly ash and pulverized fuel ash (PFA) may act as pozzolanas.

-

Gas Forming Or Air Entraining Admixtures

z Gas forming admixtures are used to liberate gas in fresh concrete so as to form aerated or foam concrete, which is lightweight and provides

better thermal insulation.

z To improve resistance against frost action

-

Bonding Admixtures

These admixtures improve the bond of fresh concrete with the already hardened concrete.

-

Sealing Agents

These admixtures reduce the capillary absorption of water by the concrete.

Curing

Curing is the process in which the concrete is protected from loss of moisture and kept within a reasonable temperature range

- To ensure the quality of the finished product

- Low temperature slow the rate of hydration

-

Excessive evaporation of water = surface shrinkage =

cracks.

Methods of curing

- Ponding

- Sprinkling

- Wet covering (burlap; made of jute plant)

- Water proof paper

- Plastic film

- Membrane

- Steam curing

- To ensure the quality of the finished product

A period of 7 days is often specified

Mixing & transporting of concrete

- Generally 70-100 revolutions at the mixing speed (6-8 rpm) are required.

- Concrete must discharged from ready mixed trucks

| within 1 1/2 hours | or |

300 drum |

revolutions |

| (whichever comes | first) |

according |

to ATSM |

| requirement. |

- Concrete should poured closer to its final position and not allowed to fall freely to avoid segregation.

- Vibration: consolidate the concrete and fill all voids.

-

Over vibration: for about 15 seconds will cause segregation in concrete.

Concrete Vibrator

A vibrator is a mechanical device to generate vibrations.

It is used to liberate voids from the concrete and densify the concrete.

Types

- Needle Vibrator

- Surface Vibrator

- Vibrating Table

Joints

- Needle Vibrator

-

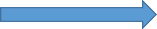

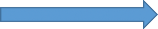

Expansion Joints: The joints provided to accommodate the expansion of adjacent parts in a building are known as expansion joints.

-

Contraction joints The joints introduced in concrete structures to localize shrinkage movements are known as contraction joints.

-

Construction joints are placed at stopping places in the process of construction.

Lime

Lime is one of the most important and largely used building materials. In fact, it used to be the main cementing material before the advent of Portland cement.

Its proportion in cement is used in the production of cement carefully.

It is used to reduce acidity in water.

It is also used in agriculture to remove soil acidity

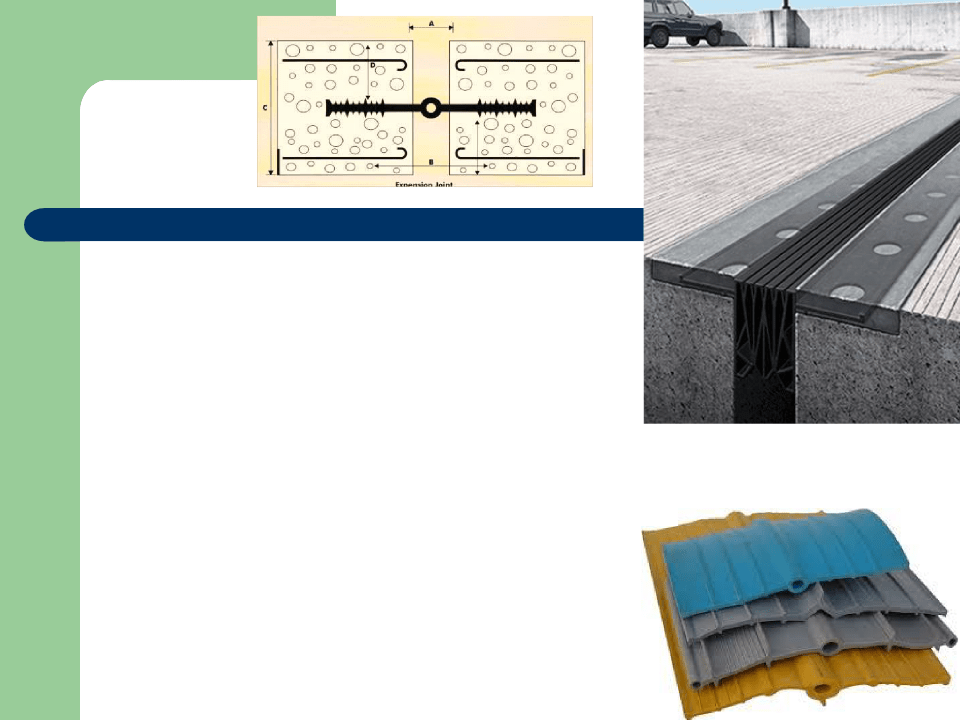

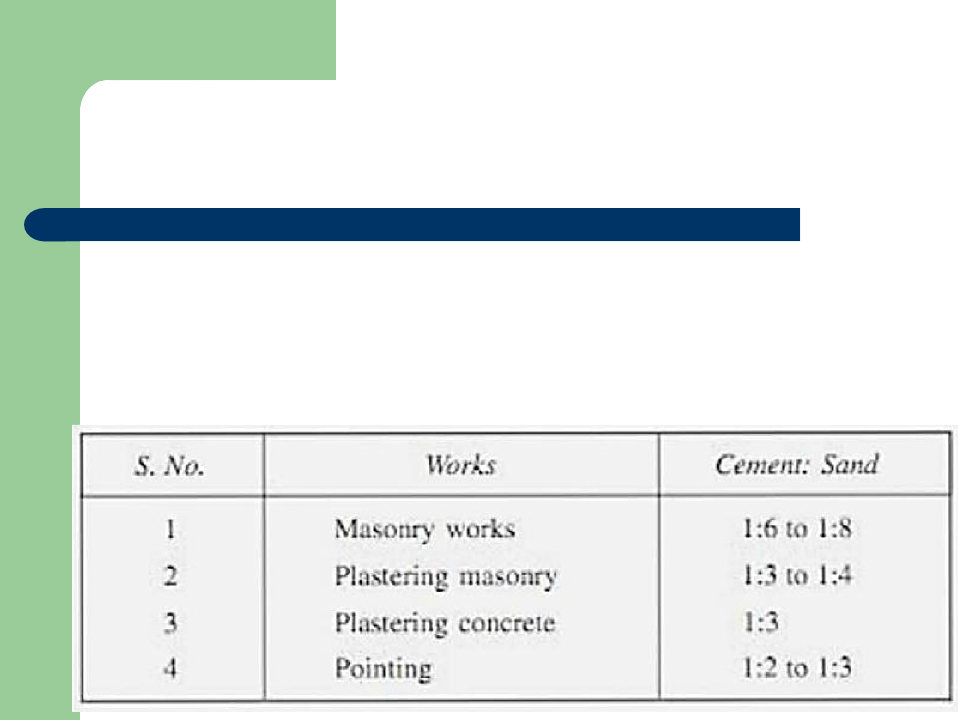

Mortar

Mortar is a workable paste used to bind construction blocks together and fill the gaps between them.