Design Principles of Concrete Structures

Lecture 15

Two way slab design

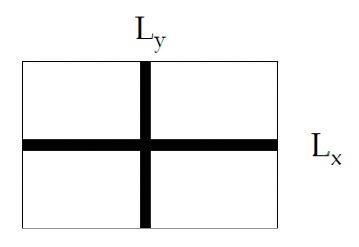

Two-Way Edge Supported Slabs

Two-Way Slabs

Slab resting on walls or sufficiently deep and rigid beams on all sides. Other options are column supported slab e.g. Flat slab, waffle slab.

Isolated Two Way Slab

Design Methods

- ACI co-efficient method

- Direct design method

- Equivalent frame method

- Finite element method

Notes

-

In two-way slabs shorter direction strip carry greater

%age of load.

- Steel will be more in shorter direction.

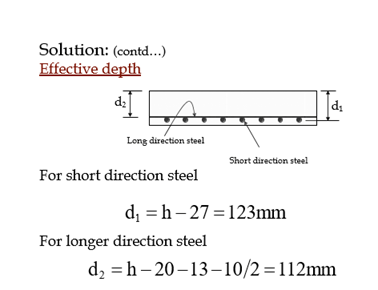

- Shorter direction steel will be placed near the outer edge to get more “d” means more lever arm to get more flexural capacity.

ACI Co-efficient Method

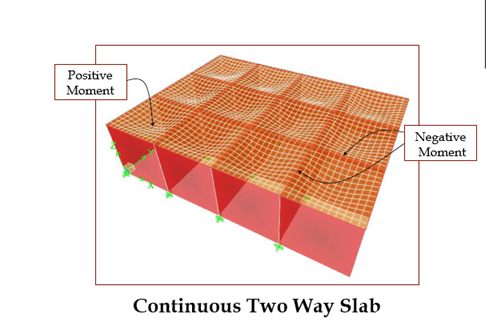

Unit width strip is taken in both directions. The strip is

designed separately for +ve and –ve moment.

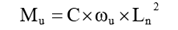

C = ACI co-efficient

ωu = Slab load

“C” depends upon the end conditions of slab and the aspect ratio.

Three tables are available for “C”

- Dead load positive moment

- Live load positive moment

- -ve moment

M+ coefficients are increased by 25 % and M– coefficients are reduced by 10 % to get the result more closer to accurate solution.

Minimum Depth of 2-Way Slab for Deflection

Control

According to ACI-318

hmin = (inner perimeter of slab panel)/180

≥ 90 mm

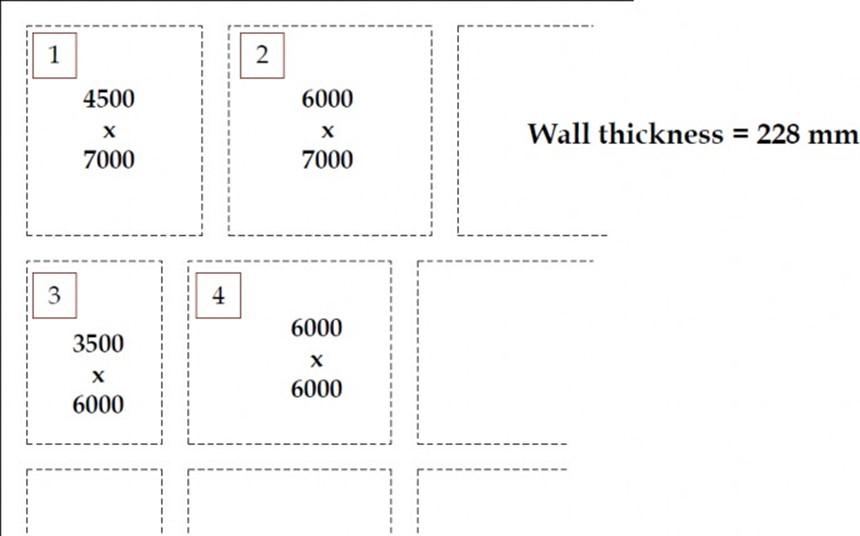

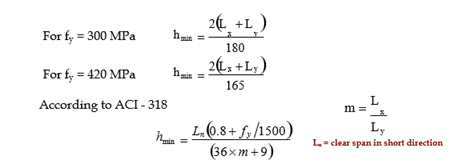

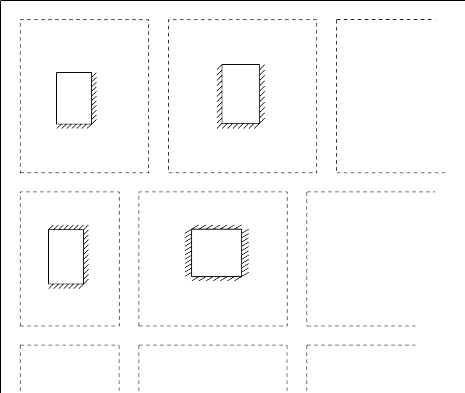

Example: Design the 4 marked slab panels of an ordinary house. Use US customary bars. fc’= 17.25 MPa fy = 300 MPa

Solution: Panel Edge Conditions

Panel # 1

Lx = 4.5m , Ly = 7.0m

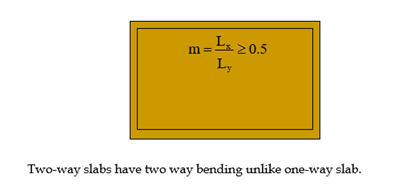

m = 0.64 > 0.5, 2-way slab

Panel # 2

Lx = 6.0m , Ly = 7.0m

m = 0.86> 0.5, 2-way slab

Panel # 3

Lx = 3.5m , Ly = 6.0m

m = 0.58 > 0.5, 2-way slab

Panel # 4

Lx = 6.0m , Ly = 6.0m

m = 1 > 0.5, 2-way slab

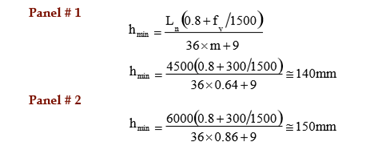

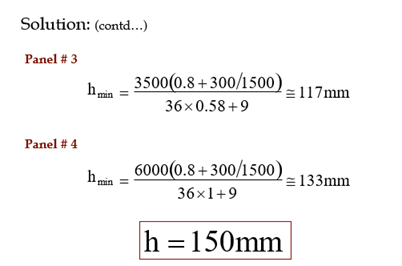

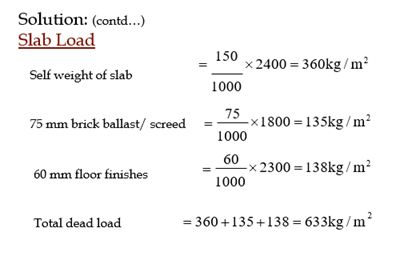

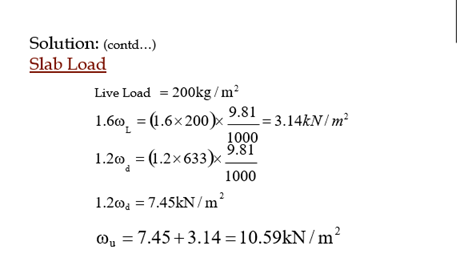

Solution: (contd…)

Slab Thickness

Generally same depth is preferred for one monolith slab. Calculate hmin for all the

panels and select the largest value.

Solution: (contd…)

Minimum Steel

As min= 0.002bh

As min= 0.002 ´1000 ´150

As min= 300mm2For a unit strip

Concluded