Design Principles of Concrete Structures

Lecture 9

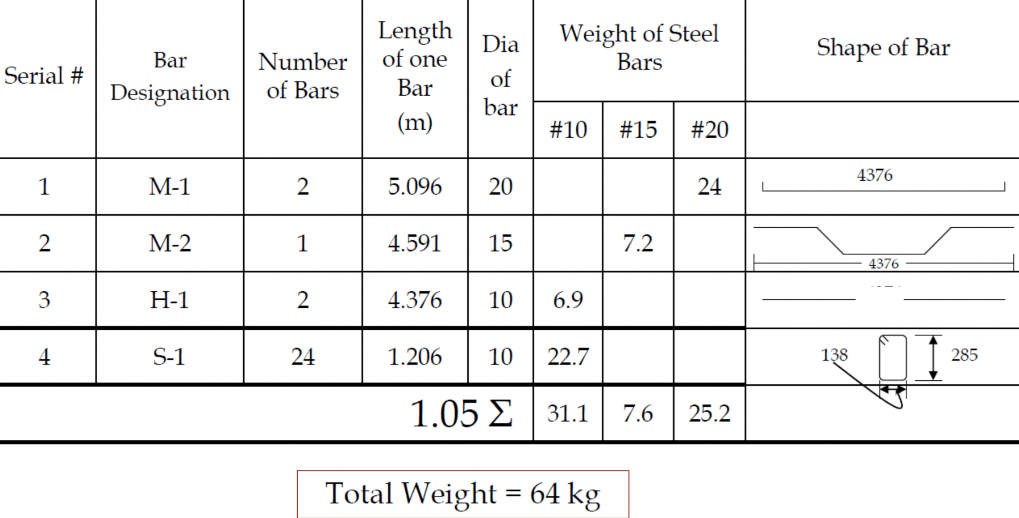

Bar Bending Schedule

Bar Bending Schedule

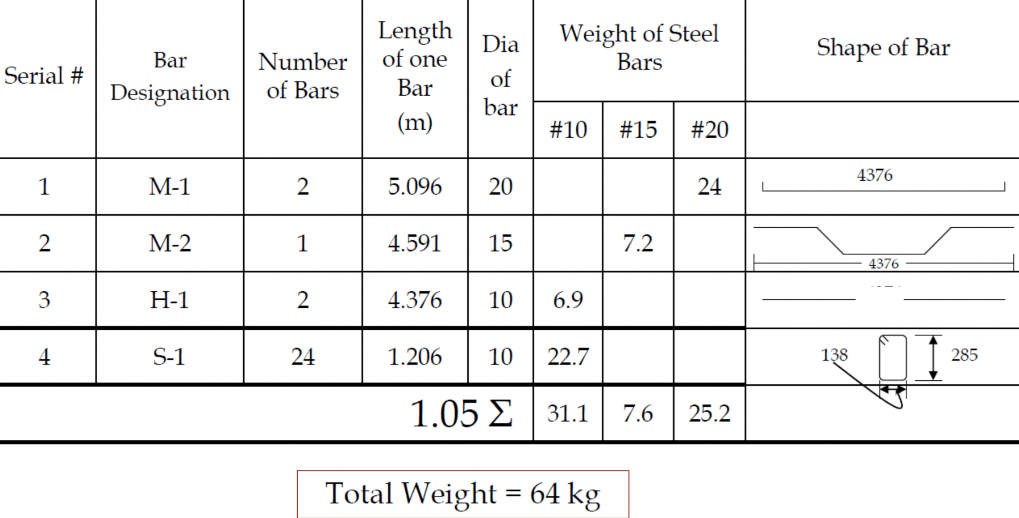

| Serial # | Bar Designation | Number of Bars |

Length of one Bar |

Dia of bar |

Weight of Steel Required |

Shape of Bar |

||||

| #10 | #13 | #15 | #19 | #25 | ||||||

|

1 |

M-1 |

#25 |  |

|

||||||

|

2 |

S-1 |

#10 |  |

|

||||||

|

3 |

H-1 |

#15 |  |

|

||||||

Σ

Total weight of steel = 1.05Σ , 5% increase, for wastage during cutting and bending

Bar Bending Schedule (contd…)

Bar Bending Schedule (contd…)

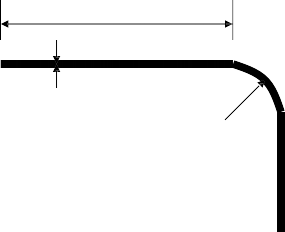

90o-Standard Hooks (ACI)

Total Length = L + 18db For R 6db

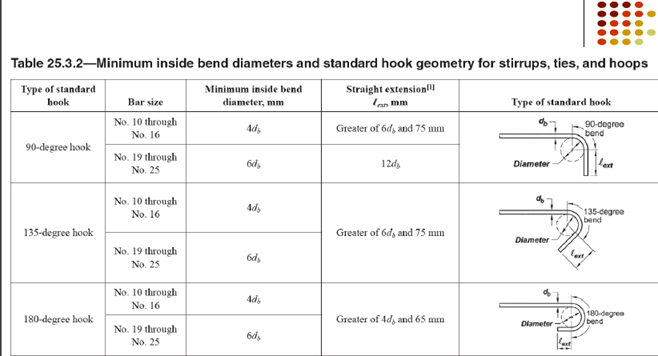

Table 25.3.2-Minimum inside bend diameters and standard hook geometry for stirrups, ties, and hoops

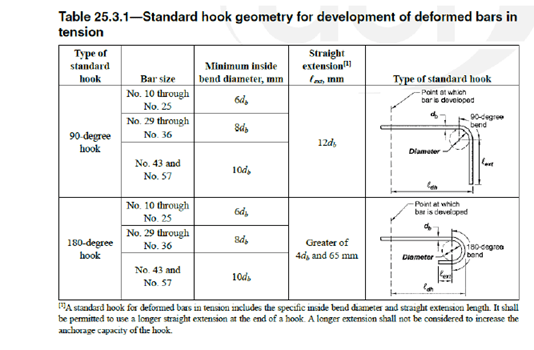

Table 25.:3.1I – Standard hook geometry for Development

of deformed bars in tension

Bar Bending Schedule (contd…)

Bar Bending Schedule (contd….)

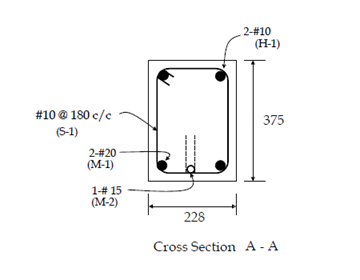

M-1 = 4000 + 2 x 228 – 2 x 40 + 2 x (18 x 20)= 5096

h = 375 – 2 x 40 – 2 x 10 – 2 (15/2) = 260

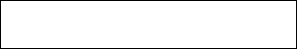

M-2 = 4000 + 2 x 228 – 2 x 40 + (0.414 x 260) x 2= 5091

H-1 = 4000 + 2 x 228 – 2 x 40= 4376

Bar Bending Schedule (contd….)

Shear stirrups

Number of Bars = 4000 /180 +1 = 24

a = 375 – 2 x 40 – 10 = 285 mm

b = 228– 2 x 40 – 10 =138 mm

Total length of S-1 = 2 (138 + 285 + (4×10 + 75)) = 1076 mm

Bar Bending Schedule

Design of Singly Reinforced Beam by Strength Method

(for flexure only)

Data:

Load, Span (SFD, BMD)

fc’, fy, Es

Architectural depth, if any Required:

Dimensions, b & h

Area of steel

Detailing (bar bending schedule)

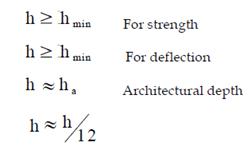

Design of Singly Reinforced Beam by Strength Method

Procedure:

-

Select reasonable steel ratio between ρmin and ρmax. Then find b, h and As.

- Select reasonable values of b, h and then calculate ρ and As.

-

Using Trial Dimensions

-

Calculate loads acting on the beam.

-

Calculate total factored loads and plot SFD and BMD. Determine Vumax and Mumax.

-

Select suitable value of beam width ‘b’. Usually between L/20 to L/15. preferably a multiple of 75mm or 114 mm.

Round to upper 75 mm

-

- Decide the final depth.

Preferably “h” should be multiple of 75mm. Recalculate “d” for the new value of “h”

-

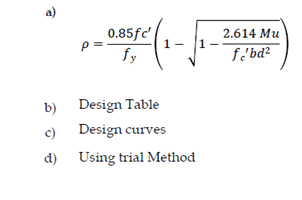

Calculate “ρ” and “As”.

Four methods

-

Check As ≥ As min.

As min = ρmin bd (ρmin = 1.4/fy to fc’ ≤ 30 MPa)

7.Carry out detailing

8.Prepare detailed sketches/drawings.

9.Prepare bar bending schedule.

Concluded