Design Principles of Concrete Structures

Lecture 7

Capacity Analysis & Rebar Guidelines

Capacity Analysis of Singly Reinforced Rectangular Beam by Strength Design method

Data

-

Dimensions, b, h, d and L (span)

- fc’, fy, Ec, Es

- As

Required

- ΦbMn

- Load Carrying Capacity

Capacity Analysis of Singly Reinforced Rectangular Beam by Strength Design method (contd…)

Solution

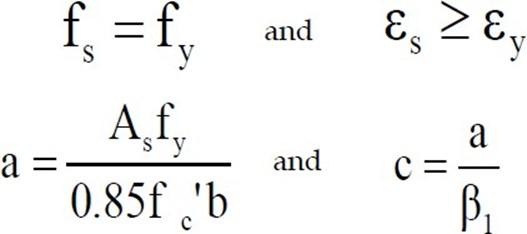

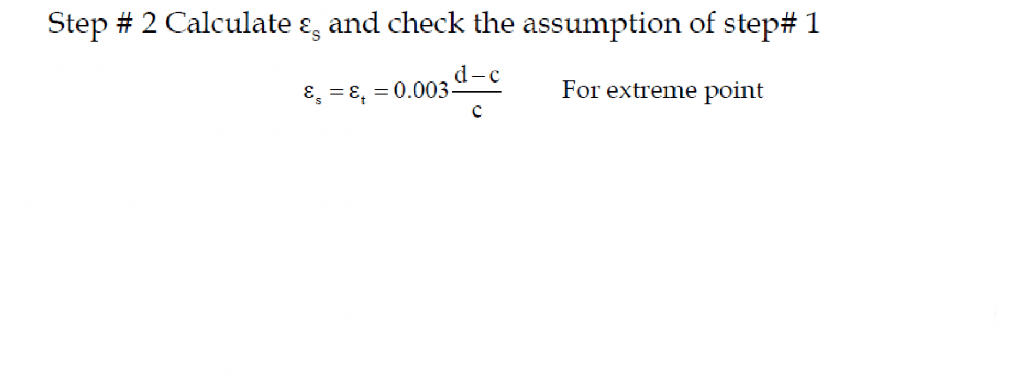

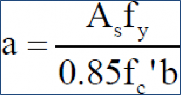

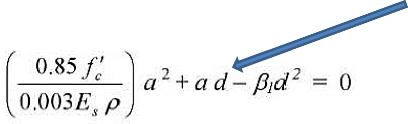

Step # 1 Calculate the depth of N.A assuming the section as under-reinforced

Capacity Analysis of Singly Reinforced Rectangular Beam by Strength Design method

Solution

Step # 3 Decide Φ factor

For εs ≥ 0.005, Φ = 0.9 (Tension controlled section)

For εs ≤ εy, Φ = 0.65 (Compression controlled section)

For εy ≤ εs ≤ 0.005, Interpolate value of Φ (Transition Section)

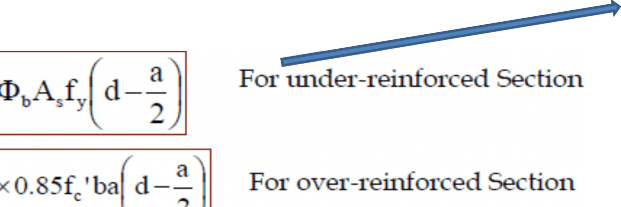

Step # 4 Calculate ΦbMn

Capacity Analysis of Singly Reinforced Rectangular Beam by Strength Design method

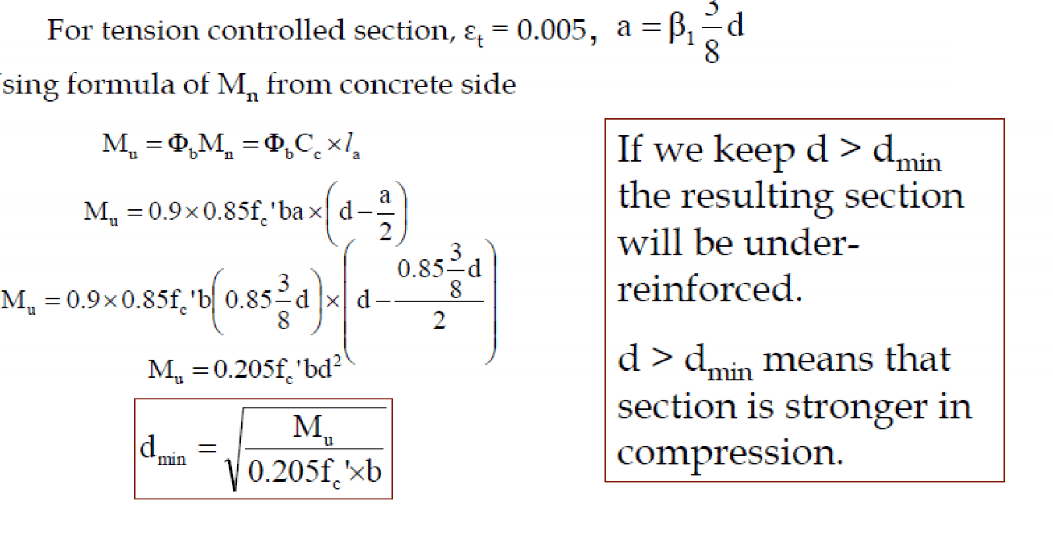

Alternate Method

Step # 1 to step # 3 are for deciding whether the section is

over reinforced or under-reinforced. Alternatively it can be done in the following manner.

- Calculate ρ and ρmax if ρ < ρmax section is under- reinforced.

-

Calculate dmin, if d ≥ dmin, section is tension controlled

Selection of Steel Bars for Beams

- When different diameters are selected the maximum difference can be a gap of one size.

- Minimum number of bars must be at least two, one in each corner.

- Always Place the steel symmetrically.

-

Preferably steel may be placed in a single layer but it is

allowed to use 2 to 3 layers.

- Selected sizes should be easily available in market.

- Small diameter (as far as possible) bars are easy to cut and bend and place.

Selection of Steel Bars for Beams (contd…)

-

ACI Code Requirements

There must be a minimum clearance between bars.

- Concrete must be able to flow through the reinforcement.

-

Bond strength between concrete and steel must be fully developed.

Minimum spacing must be lesser of the following

- Nominal diameter of bars

- 25mm in beams & 40mm in columns

-

1.33 times the maximum size of aggregate used.

We can also give an additional margin of 5 mm.

Selection of Steel Bars for Beams (contd…)

- Nominal diameter of bars

- Concrete must be able to flow through the reinforcement.

- A minimum clear gap of 25 mm is to be provided between different layers of steel

- The spacing between bars must not exceed a maximum value for crack width control, usually applicable for slabs

What is Detailing?

- Deciding diameter of bars

- Deciding no. of bars

- Deciding location of bent-up and curtailment of bars

- Making sketches of reinforcements.

Concrete Cover to Reinforcement

Measured as clear thickness outside the outer most steel bar.

Purpose

- To prevent corrosion of steel

- To improve the bond strength

- To improve the fire rating of a building

- It reduces the wear of steel and attack of chemicals specially in factories.

Concrete Cover to Reinforcement (contd…)

ACI Code, Minimum Clear Cover Requirements

| 1. | Concrete permanently exposed to earth, |

75 mm |

| 2. | Concrete occasionally exposed to earth or weather, | |

|

50 mm |

|

|

40 mm |

|

| 3. | Sheltered Concrete | |

|

20 mm |

|

|

40 mm |

|

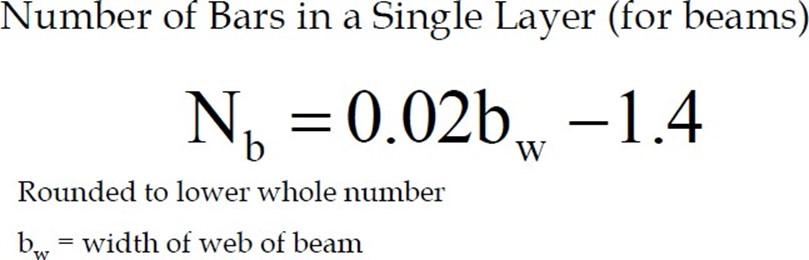

For Example

Beam with width 300 mm

Number of bars in single layer = 0.02 (300) -1.4

= 4.6 ≈ 4

Example

A singly reinforced rectangular beam has a width of 228 mm and effective depth of 450 mm. fc’ = 17.25 MPa, fy = 420 MPa. Calculate flexural capacity for the following three cases.

1. 2 # 25 bars (SI size)

2. 3 # 25 + 2 # 15 (SI)

3. Capacity for balanced steel

Concluded