Shrinkage & Creep Concrete Testing Criteria

Shrinkage

“Shrinkage is reduction in volume of concrete due to loss of water”

Coefficient of shrinkage varies with time. Coefficient of shortening is:

• 0.00025 at 28 days

-

0.00035 at 3 months

-

0.0005 at 12 months

Shrinkage = Shrinkage coefficient x Length

Excessive shrinkage can be avoided by proper curing during first 28 days because half of the total shrinkage takes place during this period

Creep

“creep is the slow deformation of material over considerable lengths of time at constant stress or load”

|

Compressive strength |

Specific Creep |

|

(MPa) |

10-6 per MPa |

|

20 |

145 |

|

30 |

116 |

|

40 |

80 |

|

55 |

58 |

Creep deformations for a given concrete are practically proportional to

the magnitude of the applied stress; at any given stress, high strength concrete show less creep than lower strength concrete.

How to calculate shortenings due to creep? Consider a column of 3m which is under sustained load for several years.

Compressive strength, fc’ = 30 MPa Sustained stress due to load = 10 MPa

Specific creep for 28 MPa fc’ = 116 x 10-6 per MPa Creep Strain = 10 x 116 x 10-6 = 116 x 10-5 Shortening due to creep = 3000 x 116 x 10-5

= 3.48 mm

Specified Compressive Strength Concrete, fc’

“28 days cylinder strength of concrete”

-

The cylinder has 150mm dia (6″) and 300mm (12″) length.

-

According to ASTM standards at least two cylinders should be tested and their average is to be taken.

ACI 318 code:

For concrete designed and constructed in accordance with ACI code, fc’ shall not be less than 17 Mpa (2500 psi)

-

Specified Concrete Compressive Strength, fc’

-

BS specifies the compressive strength in terms of cube strength.

- Standard size of cube is 6″x6″x6″

-

BS recommends testing three cubes and taking their average as the compressive strength of concrete

Cylinder Strength = (0.75 to 0.8) times Cube Strength

Relevant ASTM Standards

“Methods of Sampling Freshly Mixed Concrete” (ASTM C 172)

Practice for Making and Curing Concrete Test Specimens in Field” (ASTM C 31)

“Test Methods for Compressive Strength of Cylindrical Concrete Specimen” (ASTM C 39)

Testing of Samples for Compressive Strength

Cylinders should be tested in moist condition because in dry state it gives more strength.

ACI 26.12.2: Samples for strength tests of each class of concrete placed

each day shall be taken :

-

Not less than once a day

-

Not less than once for each 110 m3 of concrete.

-

Not less than once for each 460 m2 of concrete area for slabs or walls..

Code allows the site engineer to ask for casting the test sample if he regards it necessary.

Acceptance Criteria for Concrete Quality

ACI 26.12.3: Strength level of an individual class of concrete shall be considered satisfactory if

both of the following requirements are met:

- Every arithmetic average of any three consecutive strength tests equals or exceeds fc’.

- No individual strength test (average of two cylinders) falls below fc’

-

by more than 3.5 MPa (500 psi) when fc’ is 35 MPa

(5000 psi) or less; or

- by more than 0.10fc’ when fc’ is more than 35 MPa

Example

For Required fc’ = 20 MPa, if following are the test results of 7 samples

• 19,20, 22, 23, 19, 18, 24 MPa

Mean 1 = (19 + 20 + 22) / 3 = 20.33 MPa

Mean 2 = (20 + 22 + 23) / 3 = 21.67 MPa

Mean 3 = (22 + 23 + 19) / 3 = 21.33 MPa

Mean 4 = (23 + 19 + 18) / 3 = 20.00 MPa

Mean 5 = (19 + 18 + 24) / 3 = 20.33 MPa

- Every arithmetic average of any three consecutive strength tests equals or exceeds fc’.

- Non of the test results fall below required fc’ by 3.5 MPa.

Considering these two point the quality of concrete is acceptable

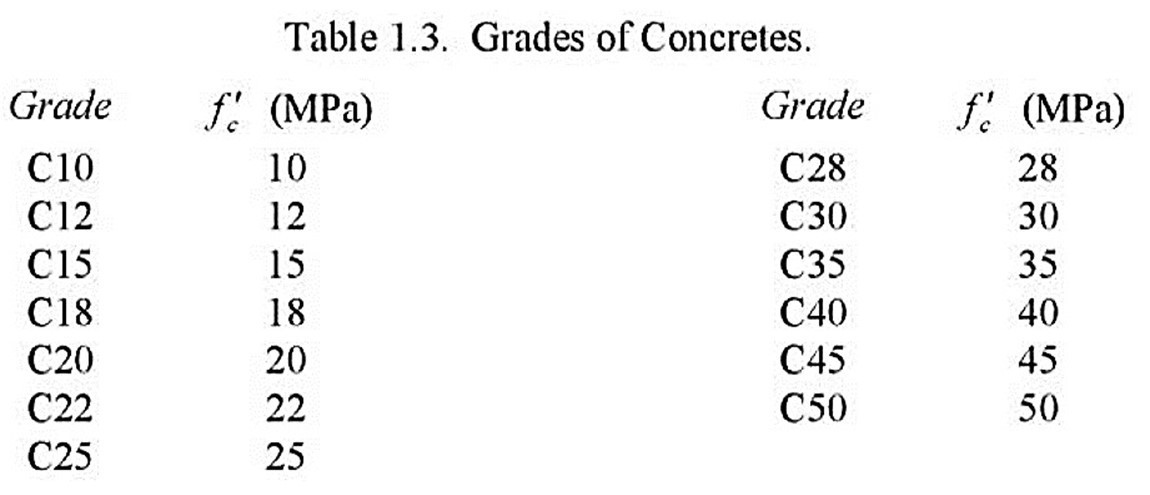

The following grades of concrete may be defined based on the

minimum concrete compressive strength:

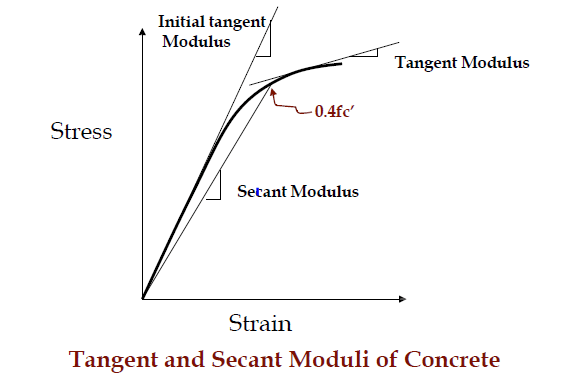

Stress Strain Curve of Concrete

Modulus of Elasticity

Concrete is not an elastic material therefore it does not have a fixed value of modulus of elasticity

Modulus of Elasticity (contd…)

Secant modulus (Ec) is the one which is being used in design.

Ec = 0.043 wc1.5√fc’

wc = density of concrete in kg/m3

fc’ = specified cylinder strength in MPa

For normal weight concrete, say wc = 2300 kg/m3

Ec = 4700√fc’

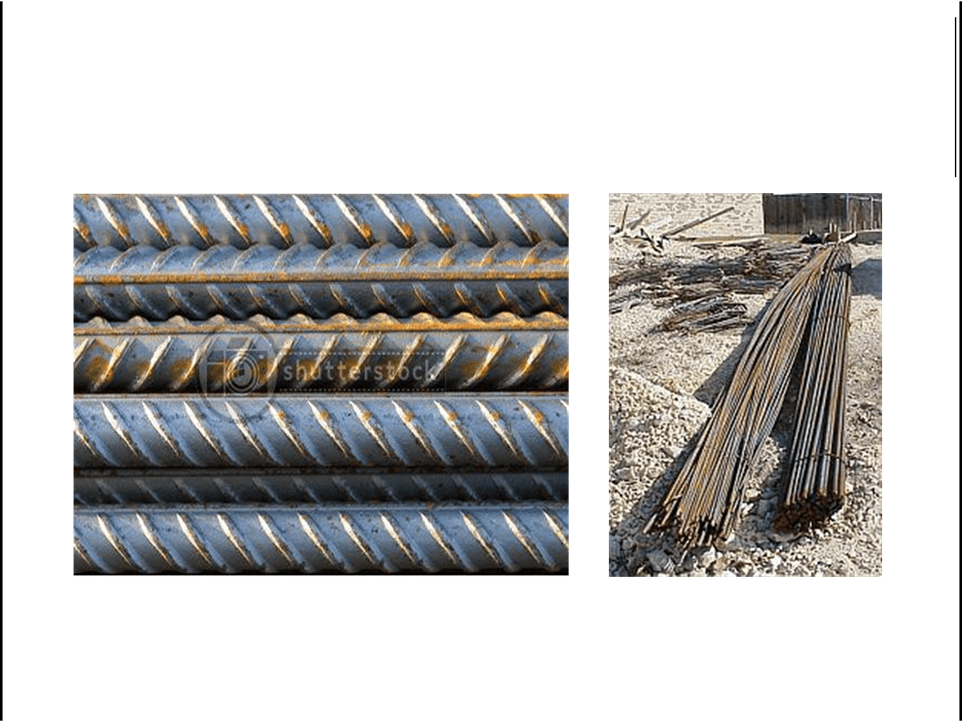

Reinforcing Steel

Steel bars are:

Plain

Deformed (currently in use)

Deformed bars have longitudinal and transverse ribs. Ribs provide a good bond between steel and concrete. If this bond fails steel becomes in effective.

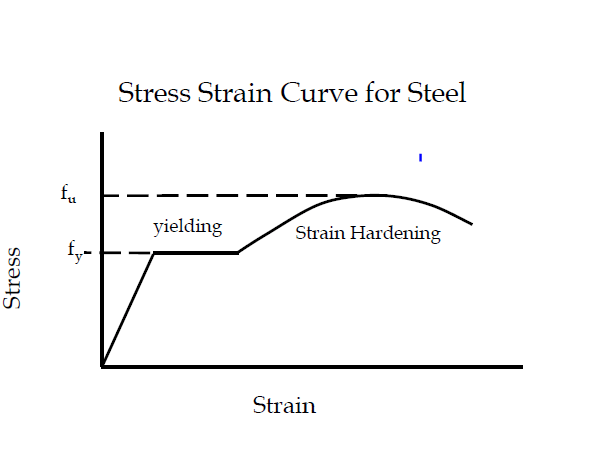

The most important properties for reinforcing steel are:

Young’s modulus, E (200 GPa)

Yield strength, fy Ultimate strength, fu Size and diameter of bar

Reinforcing Steel

Steel Grade Designation

- Grade 300, fy = 300 MPa

- Grade 420, fy = 420 MPa

- Grade 520, fy = 520 MPa

THANK YOU