What is a Chemical Anchor?

And Why Use Them?

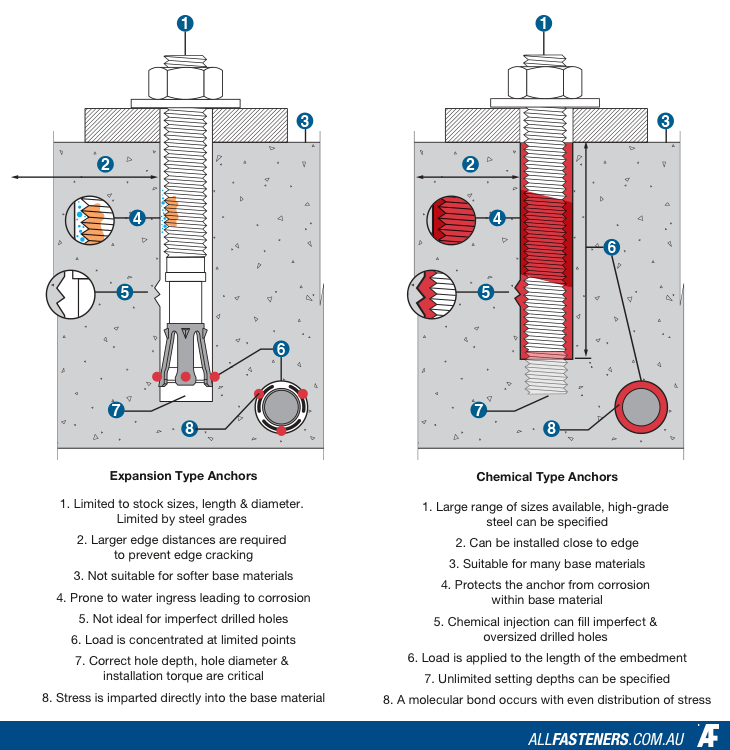

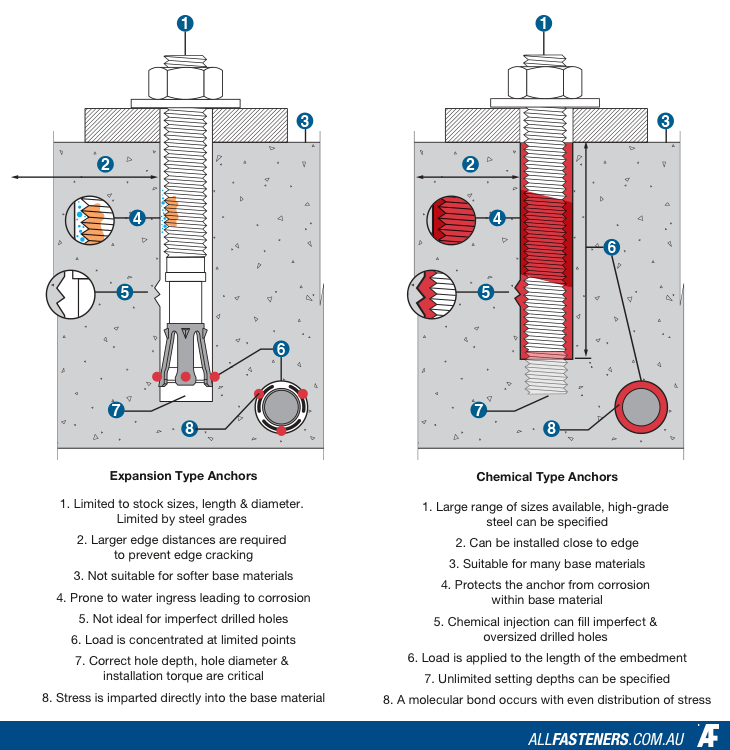

Chemical anchoring is a technique for fastening to concrete and similar substrates that provides more flexibility than mechanical anchoring.

A mechanical anchor, such as a sleeve anchor, Dynabolt®, wedge anchor or drop-in anchor, is inserted in the concrete and expands upon tightening. This expansion causes the anchor to grip the wall of the hole and provide an extremely strong hold. Whilst being a very popular and economical option, there are, however, some limitations.

So, what is a chemical anchor’s advantage? With chemical anchoring, a resin is injected into the hole prior to insertion of the stud. With this, the chemical naturally fills in all irregularities and therefore makes the hole airtight and water proof, with 100% adhesion.

And with mechanical anchors, each predetermined size—length (embedment) and diameter—has its own load capacity limits. Chemical anchors have virtually unlimited embedment depth, so you can embed any length of rod into the hole to increase the load capacity. And if you choose to use a larger-diameter hole with a thicker rod, you increase load capacity again.

Chemical anchors —also known as chemical studs—can also be placed towards the edge of concrete substrates and through masonry block. The non-expanding nature of a chemically-held rod drastically reduces the chance of the surrounding concrete cracking. This is very good for securing railings close to edge, or concrete stairs, and similar applications. Finally, chemical anchoring gives you the opportunity to make slight adjustments to the stud’s alignment during the chemicals open working time, whereas a mechanical anchor needs a hole to be drilled millimetre-perfect every time to correct depth and angle, and if it isn’t, it cannot be used.

The downside of chemical anchors, to some contractors, are that they are more complicated to install, and incorrect installation habits can jeopardize the anchor’s capacity. Following correct installation methods are critical, Allfasteners offers training and instruction in this. They may also be considered more expensive than mechanical anchors. However, apples should be compared to apples in this instance, as both fasteners are often used for very different things, especially when satisfying engineers’ requirements. Seek advice on this, if there is ever any doubt with what to choose.

Glass Capsule Chemical Adhesive Anchor

Product Description

The resin capsule RSB is a system component of the fischer Superbond-System FSB for the introduction of high loads in cracked and non-cracked concrete. European Technical Approval Option 1 for cracked concrete including seismic loads in performance category C1 and classification into fire resistance class R120 offer added safety. Heavy steel constructions, sound barriers, and tall shelving are secured with the resin capsules, for example. The fixtures are secured with the fischer threaded rod RG M and the fischer internal threaded anchor RG MI. fischer offers a standard capsule and a short capsule. To introduce higher loads, two short capsules can be placed into the drill hole. The short hardening time means that fast work progress is still possible

Advantages

- The pre-portioned resin capsule RSB is especially cost-effective for individual applications and overhead installations.

- The ideal solution for difficult conditions and installations with no waiting time due to fast hardening: Approval-compliant processing down to -30°C, also approved for water-filled and diamond-drilled holes as well as for seismic applications in performance category C1 (only in conjunction with RG M).

- For each diameter, up to three anchorage depths can be realised with the threaded rod RG M through a combination of the resin capsules RSB mini.

- The use of the internal threaded anchor RG M I enables the surface-flush removal of the fixture and the reuse of the fixing point.

Chemical fixings

Chemical fixing solutions for heavy-duty fixings in concrete and masonry.

Chemical fixings are the fixing solution for transferring extreme loads in concrete, aerated concrete or masonry expansion-free. fischer has a unique competence in developing and manufacturing chemical fixing solutions. This allows an optimum and secure solution to be offered for all applications, even under extreme construction site conditions such as wet, cold or heat: approved systems with resin capsules, injection mortars, threaded rods, internal threaded rods, anchor sleeves, accessories and processing equipment.