Masonry structures are those structures which are built from individual units laid in and bound together by mortar. The common materials of masonry construction are bricks, stones, marble, granite, limestone, concrete block, glass block and tiles etc.

Constructing with building stones is the simplest and one of the oldest building methods in the world.

Today masonry is still the most used building material. The earliest masonry structures were constructed using primitive form of raw materials such as stone units, rammed earth. The structures often were built by placing blocks together without any bonding.

The evolution of masonry structures has resulted in development of not only more robust materials over the years but also more robust technology. The masonry structures are well known for their simplicity in

construction and economy compared to steel and reinforced concrete structures.

Use of Masonry Structures

Masonry is commonly used building material for structural and non-structural purposes. Additionally, there is growing interest for masonry structures because of its 3-phase efficiency – in production phase, in construction phase and in operation phase. Masonry structures provide more comfortable living environment inside which will ultimately reduce the amount of energy spent to improve comfort condition of houses built with other materials such as steel.

Moreover, the appeal of masonry structures for their user comfortability, aesthetic beauty and closeness to the nature has attracted many for masonry buildings.

- Other uses of masonry structures are in arches, partition walls, retaining walls, dams, coffer dams, etc.

- Masonry is also used for finishing works in buildings and also for cladding and roofing.

- The Hanging Garden, one of the Seven Wonders of the World, is a typical example of masonry

structure.

- The Great Wall of China, the largest man-made object on earth;

- The Great Medieval Castle of Marlboro, Portland, which is the size of a small town;

- The Taj Mahal, India;

-

The 1200 miles of sewers which the Victorians built under the city of London are some other

examples of masonry structures.

-

The oldest serving masonry structure is said to be an arch bridge over Meles River at Smyrna,

Turkey.

Advantages of Masonry Structures

- The use of materials such as bricks and stones can increase the thermal mass of the buildings.

- Most types of masonry typically will not require painting and so can provide a structure with reduced life-cycle costs.

- Masonry structures are heat resistant and thus provide good fire protection.

- Masonry walls are also good sound and noise resistant.

- Masonry structures built in compression preferably with lime mortars can have a useful life of more than 500 years as compared to 30 to 100 for structures of steel or reinforced concrete.

Disadvantages of Masonry Structures

- Extreme weather causes degradation of masonry wall surfaces due to frost damage. This type of damage is common with certain types of bricks, though rare with concrete blocks.

- Masonry tends to be heavy and must be built upon a strong foundation, such as reinforced concrete, to avoid settlement and cracking.

- Masonry construction does not lend itself well to mechanization and requires more skilled labour than stick-framing.

Structural Limitation

Masonry units have impressive compressive strength (vertical loads) but is much lower in tensile strength (twisting or stretching). The tensile strength of masonry walls can be strengthened by thickening the wall, or by building masonry piers (vertical column or ribs) at intervals where practical, steel reinforcement can be added.

Construction Technology, Hollow Block and Compressed Earth Block

Hollow Blocks

Hollow Blocks

Hollow Blocks are precast concrete units made of appropriate mixture of cement and aggregates such as sand, river bed gravel, crushed stone etc. It can be produced in different shape and sizes for all construction to fit different construction needs and designs. Most of them are made in full and half length units as per modular design. These hollow blocks are prepared by concrete block technology.

Concrete Masonry Unit (CMU)

Concrete Block Technology:

It is based on the principle of densification of a lean concrete mix to make regular shaped, uniform, high performance masonry units. Concrete Block Technology can be easily adopted to suit special needs of users by modifying design parameters such as mix proportion, water/cement ratio and type of production system. It is an effective means of utilizing wastes generated by stone crushers, quarrying and stone processing units. The technology has high performance in areas where raw materials are easily available.

Advantages of Hollow Concrete Blocks:

- Reduces cost investment at least 30% compared to fired clay brick masonry.

- Reduces more than 50% energy (MJ/m2) compared to fired clay brick masonry.

- Easy and speedy construction.

- Have good thermal and sound insulation.

- It can be produced in different shapes and sizes to fit different construction needs and designs.

- National and international standards are available and hollow concrete block technology is accepted by the building code.

- Reduces dead load.

- Reduces maintenance cost as there is no salt efflorescence.

- Reduces the thickness of plaster due to size accuracy and less cement consumption due to fewer joints.

- Makes environment friendly as fly ash used as one of the raw materials.

- These are durable and maintenance free.

-

It acts as damp-proof as it has low water absorption. Technical Specifications of Concrete Block:

i. Typical Size = 406 x 203 x 203 mm (16″ x 8″ x 8″) or 300 x 200 x 150 mm (12″ x 8″ x 6″)

- Average compressive strength at 28 days = 5 MPa to 10 MPa

- Mix Proportion = 1:12-14 (1 part cement: 12-14 part sum graded aggregates)

- Water absorption in 24 hours: < 10% by weight of block

Compressed Earth Blocks (CEB)

The compressed earth blocks are masonry units of cuboidal shape and are manufactured by compacting raw material earth mixed with a stabilizer such as cement or lime under a pressure of 2 to 4 MPa using manual soil press such as Ball ram. It is also termed as stabilized compressed earth block.

The basic principle of all the machines is the compaction of raw earth to attain dense, even sized masonry. Some of the hydraulic machines can even manufacture interlocking blocks. These interlocking blocks are highly suitable for speedy and mortar less construction.

Advantages of Compressed Earth Blocks:

- A Local Material: The production is made on the site itself or in the near areas. Thus, it will save transportation, fuel, time and money.

- An Adapted Material: Being produced locally, it is easily adapted to various needs: technical, social and cultural habits.

3. A job creation opportunity: CEBs allow unskilled and unemployed people to learn a skill, get a job and rise in social status.

- Limiting Deforestation: Firewood is not needed to produce CEBs; so, it will save the forests.

- It has high strength and durability and needs minimum maintenance.

- A Transferable Technology: It is a simple technology requiring semi-skills, easy to get. Simple villagers will be able to learn how to prepare it in a few weeks. Efficient training centre will transfer the technology in a week time.

- Market Opportunity: According to the local context (material, labour, equipment, etc.), the final price will vary, but in most of the cases it will be cheaper than fired bricks.

- Reducing Imports: As it is locally produced, there is no need to import heavy and expensive building materials from far away.

- Energy efficient and Eco-friendly: It requires less energy than fired bricks. The pollution emission will be thus less.

- Fire resistance, thermal and sound insulation is good. Disadvantages of Compressed Earth Block:

- Proper soil identification is required or lack of soil.

- Ignorance of the basics of production and use.

- Low technical performances compared to concrete.

- Untrained teams producing bad quality products.

- Low social acceptance due to counter examples (by unskilled people, or bad soil and equipment).

- Over-stabilization through fear or ignorance, implying outrageous costs.

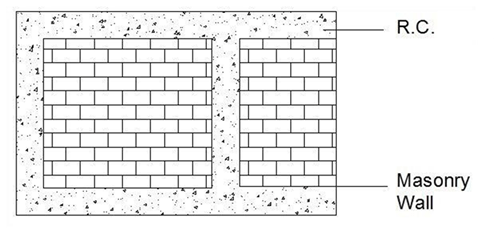

Masonry as Infill Walls

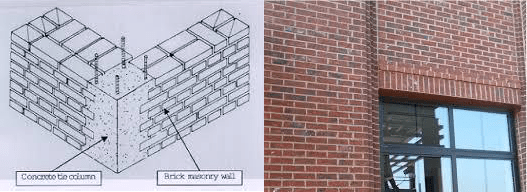

Infill walls are the walls which are confined on all four sides with reinforced concrete or reinforced masonry as vertical and horizontal confining element, which are not intended to carry either vertical or horizontal loads and are consequently not designed to perform as moment-resisting frames. Masonry is usually used as infill wall, and is also known as confined masonry.

In the case of masonry-infilled frames, the R.C. frame structure, which is designed to resist vertical and seismic loads without infill, is constructed first. Masonry filler walls are very often constructed as non- structural elements after the completion of the main R.C. structure.

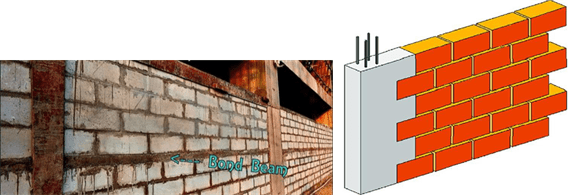

As the experimental investigations and the experiences obtained after earthquakes have shown, confining the masonry walls with bond-beam and tie column results in:

- Improvement in connection between structural walls.

- Improvement in the stability of slender structural walls.

- Improvement in strength and ductility of masonry panels.

- Reduction in the risk of disintegration of masonry panels damaged by the earthquake.

In order to ensure structural integrity, vertical confining elements should be located at all corners and recess of the building and at all joints and wall intersections. In addition, they should be placed at both sides of any wall opening. Vertical confining elements should also be placed at all free ends of structural walls.

Reinforced and Un–reinforced Masonry

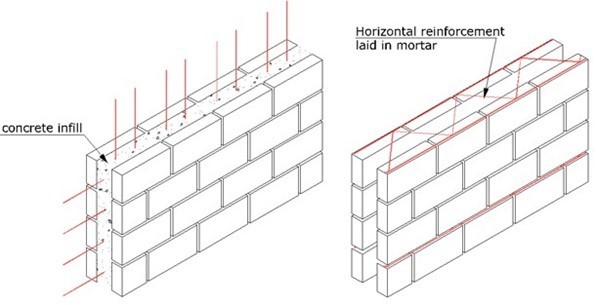

Reinforced Masonry

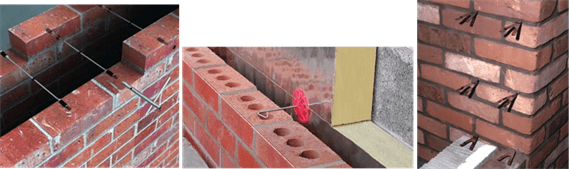

Reinforced masonry is a construction system, where steel reinforcement in the form of reinforcing bars or mesh is embedded in the mortar or placed in the holes and filled with concrete or grout. Reinforcement increases the tensile as well as compressive strength of wall. By reinforcing the masonry with steel reinforcement, the resistance to seismic loads and energy dissipation capacity may be improved significantly. To achieve this, the reinforcement should be integrated with masonry so that all materials of reinforced masonry system act monolithically when resisting gravity and seismic loading.

There are various ways in which steel reinforcement can be used in Reinforced masonry structural system. Basically, reinforced masonry system can be classified in:

- Reinforced Hollow Unit Masonry

- Reinforced Grouted Cavity Masonry

- Reinforced Pocket-type Walls

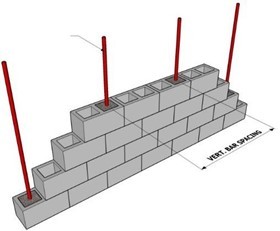

– Reinforced Hollow Unit Masonry

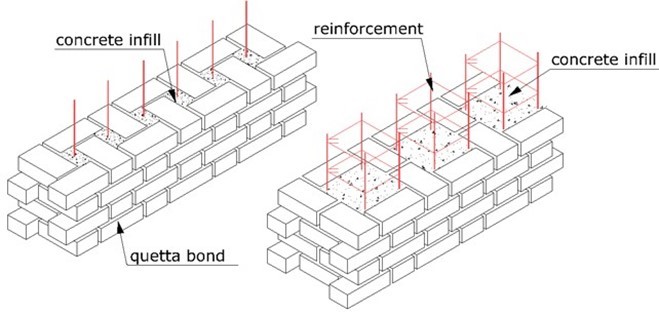

Reinforced Hollow Unit Masonry represents the basic form of reinforced masonry construction, special shaped units with vertical holes where vertical reinforcement is placed and filled with infill concrete or grout, with or without groves to accommodate horizontal, bed joint reinforcement, are used for the construction of masonry walls. Before laying the masonry units, vertical reinforcement is placed in position. Then the first course of units is laid in the mortars and horizontal bars or bed joint reinforcements are placed in the grooves or in the mortar joints. The holes containing the vertical bars are filled with either concrete or grout, and the grooves containing the horizontal steels are filled with either grout or mortar, as the construction of the wall progresses. In order to improve the resistance and depending on the shape of the units, all holes in the hollow blocks are often grouted or filled with concrete infill.

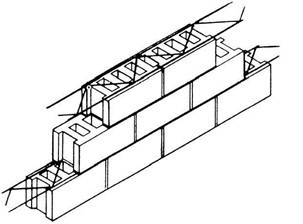

– Reinforced Cavity Masonry

It consists of two leaves (wythes) of masonry units, separated by a cavity into which the vertical and horizontal reinforcements are placed and grouted with either concrete infill or grout. The two leaves of a cavity wall are tied together with wall ties or connectors, which should be designed to carry lateral loads, induced by earthquake.

The masonry units should be laid in running or stretcher bond: vertical stacked bond is not allowed in seismic zones. The grout can be poured either as the work progresses or after the masonry units in the whole story have been laid.

In the first case, vertical reinforcing bars are placed first into position. Then, the horizontal bars and wall ties are placed and grouted as laying of courses of masonry progresses.

In the second case, the mesh of vertical and horizontal is placed first in position. Then, the masonry units are laid on each side of the mesh, connected together with wall ties. The ties should be laid in the bed joints along the same vertical line in order to facilitate the vibrating of the grout pours.

Note:

After the masonry is built to a full storey height, the cavity is filled with grout. Before grouting, all mortar droppings should be removed from the foundation or other bearing surfaces and reinforcement.

Cleanout openings should be provided to allow flushing away of mortar droppings and debris at the bottom of each pour.

- – Reinforced Pocket type Walls

Sometimes, vertical reinforcement is placed in the pockets formed in the wall by special bonding arrangement. As in the case of reinforced hollow unit masonry units, vertical reinforcing bars are placed into position before the laying of masonry units. Depending on the units used, horizontal bed joint reinforcement is placed in the mortar joints at vertical spacing not exceeding 600 mm. The pockets containing vertical bars are filled with either concrete or grout, as the construction of the wall progresses.

Un-reinforced Masonry

An unreinforced masonry is a construction system where load bearing walls, non-load bearing walls or other structures, such as dams, retaining walls etc. are made of bricks, concrete masonry units, tiles, or other masonry units that is not braced by reinforced bars or beams.

Unreinforced masonry structures are vulnerable to collapse in earthquake. One problem is that most mortars used to hold bricks together are not strong enough.

Additionally, masonry elements may ‘peel’ from the building, and fall on to occupants outside.

Hey There. I found your blog using msn. This is a very well written article.

I will make sure to bookmark it and return to read more of your useful info.

Thanks for the post. I’ll certainly comeback.