Plastic roads

Initial Development

The technology was initially developed and patented by Rajagopalan Vasudevan of the Thiagarajar College of Engineering. He developed an innovative method to reuse plastic waste to construct better, more durable and very cost-effective roads. This method will help in making roads much faster and also will save the environment from dangerous plastic waste. The roads also show greater resistance to damages caused by heavy rains. In an interview with The Better India, he explained, “The advantages of using waste plastics for road construction are many. The process is easy and does not need any new machinery. For every kilo of stone, 50 gms of bitumen are used and 1/10th of this is plastic waste; this reduces the amount of bitumen being used. Plastic increases the aggregate impact value and improves the quality of flexible pavements. Wear and tear of the roads has decreased to a large extent.”

The plastic-bitumen road-laying technique covered under a patent held by the Thiagarajar College of Engineering in 2006. Dr Vasudevan has since made it free to use for the greater good. The technology is simple and is described in a dedicated TCE website.

Plastic roads Definitions

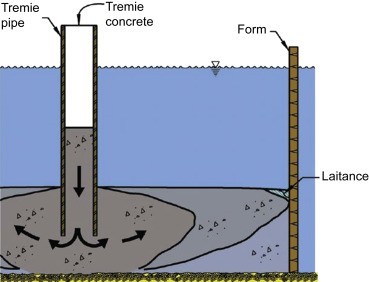

It involves

a) collecting waste plastics, including plastic carry bags, cups, soft and hard foams, and laminated plastics;

b) cleaning it by washing;

c) shredding it to a uniform size;

d) melting the waste plastics at 165 °C, and blending it with hot aggregates and bitumen and using this mixture to lay the road

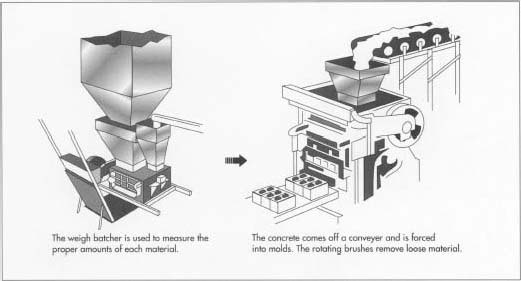

Plastic Road mixture Combination

Plastic roads developed by Rajagopalan Vasudevan consist of an asphalt mix with plastic waste incorporated into the asphalt mixture. The implementation of plastics in roads also opens a new option for recycling post consumer plastics.

Discussion

Although the concept of using waste plastic in roads is still in its early stages, with very few plastic roads currently existing in the Western world, civil engineering researchers in countries like the United Kingdom and the United States are working to design new technologies to support the safe implementation of waste plastic in road construction. One such development involves converting waste plastics into small balls that, when combined with asphalt or other common road components, create a strong, permeable surface that features hollow spaces that allow stormwater to seep through the road and more effectively recharge groundwater.

Transitioning to the use of plastic roads will lead to more manageable plastic waste and potentially, safer roads, but there are still some concerns regarding hazards that

Accompany plastic roads as they age. As these roads gradually deteriorate due to heat and light, they may dissolve into micro-plastics that give off harmful pollutants, affecting the functionality and biodiversity of soil and water resources. Creative civil engineers play a significant role in ensuring that the science behind using waste plastic for roads is accurate, and that future iterations of this concept are carried out with consideration for environmental health and safety.