Description

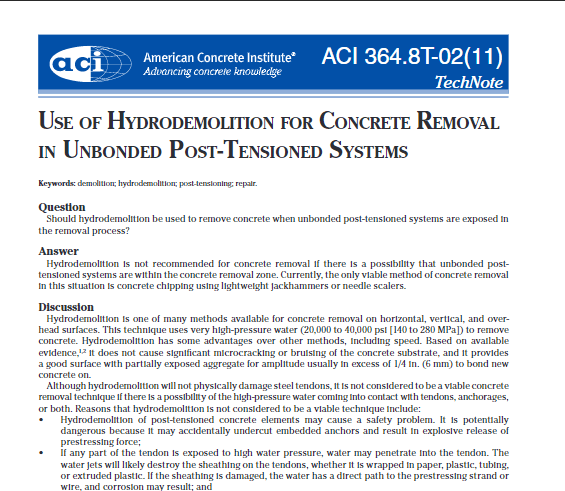

Hydro demolition is one of many methods available for concrete removal on horizontal, vertical, and over-head surfaces. This technique uses very high-pressure water (20,000 to 40,000 psi [140 to 280 MPa]) to remove concrete. Hydrodemolition has some advantages over other methods, including speed. Based on available evidence,1,2 it does not cause significant microcracking or bruising of the concrete substrate, and it provides a good surface with partially exposed aggregate for amplitude usually in excess of 1/4 in. (6 mm) to bond new concrete on.Although hydrodemolition will not physically damage steel tendons, it is not considered to be a viable concrete removal technique if there is a possibility of the high-pressure water coming into contact with tendons, anchorages, or both. Reasons that hydrodemolition is not considered to be a viable technique include:

• Hydrodemolition of post-tensioned concrete elements may cause a safety problem. It is potentially dangerous because it may accidentally undercut embedded anchors and result in explosive release of prestressing force;

• If any part of the tendon is exposed to high water pressure, water may penetrate into the tendon. The water jets will likely destroy the sheathing on the tendons, whether it is wrapped in paper, plastic, tubing, or extruded plastic. If the sheathing is damaged, the water has a direct path to the prestressing strand or wire, and corrosion may result; and

• Concrete repair projects commonly include replacement of post-tensioning strand. The water pressure used in hydrodemolition equipment can force slurry into the sheathing. When slurry and other debris exist within the sheathing, installation of a new strand becomes very difficult. When the new strand is pushed into the existing sheathing, debris within the sheathing builds up ahead of the advancing strand. This buildup of debris can cause the sheathing to rip and “ball up” in front of the leading edge of the strand. This scenario makes strand replacement very difficult and compromises the corrosion protection or sheathing over the prestressing steel.More information can be found in ACI 423.4R

-

Turnitin Instructor with AI Detection$60.00 – $110.00

Turnitin Instructor with AI Detection$60.00 – $110.00 -

SmartPLS 4.1 Processional | Lifetime activation$60.00

SmartPLS 4.1 Processional | Lifetime activation$60.00 -

EndNote Lifetime for Windows /Mac Software Full Version$8.00 – $10.00

EndNote Lifetime for Windows /Mac Software Full Version$8.00 – $10.00 -

![Use of Hydro demolition for Concrete removal in Unbonded Post-tensioned systems (ACI 364.8T-02(11)) 11 IBM SPSS Statistics [Lifetime]](https://civilmdc.com/wp-content/uploads/2022/11/IBM-SPSS-V-29-300x300.jpg) IBM SPSS Statistics [Lifetime]$10.00 – $25.00

IBM SPSS Statistics [Lifetime]$10.00 – $25.00 -

LinkedIn ALL COURSES LIFETIME Warranty$40.00

LinkedIn ALL COURSES LIFETIME Warranty$40.00 -

Product on sale

REF-N-WRITE | Premium Account Lifetime Activation$22.00

REF-N-WRITE | Premium Account Lifetime Activation$22.00 -

QuillBot’s paraphrasing tool | Premium Account 6 month | + WARRANTY$12.00

QuillBot’s paraphrasing tool | Premium Account 6 month | + WARRANTY$12.00 -

Grammarly Premium Account 6 Month |12 month$20.00 – $35.00

Grammarly Premium Account 6 Month |12 month$20.00 – $35.00 -

TURNIT1N Student (Plagiarism Checker) – 6 Month | 1 Year | 2 Years | 3 Years | 4 Years | LifeTime$9.00 – $100.00

TURNIT1N Student (Plagiarism Checker) – 6 Month | 1 Year | 2 Years | 3 Years | 4 Years | LifeTime$9.00 – $100.00